| Lost Technologies of Ancient Egypt | Source |

|

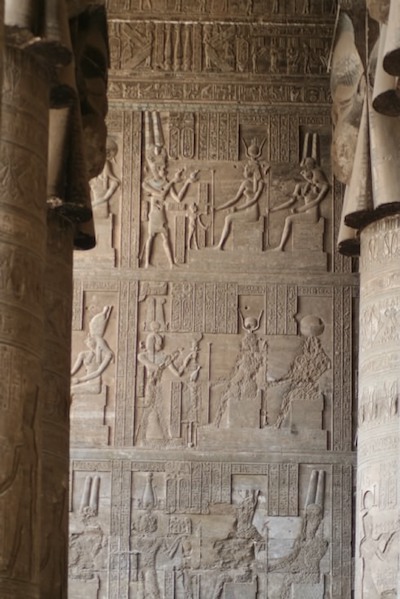

From the pyramids in the north to the temples in the south, ancient artisans left their marks all over Egypt, unique marks that reveal craftsmanship we would be hard pressed to duplicate today. Drawing together the results of more than 30 years of research and nine field study journeys to Egypt, Christopher Dunn presents a stunning stone-by-stone analysis of key Egyptian monuments, including the statue of Ramses II at Luxor and the fallen crowns that lay at its feet. His modern-day engineering expertise provides a unique view into the sophisticated technology used to create these famous monuments in prehistoric times.

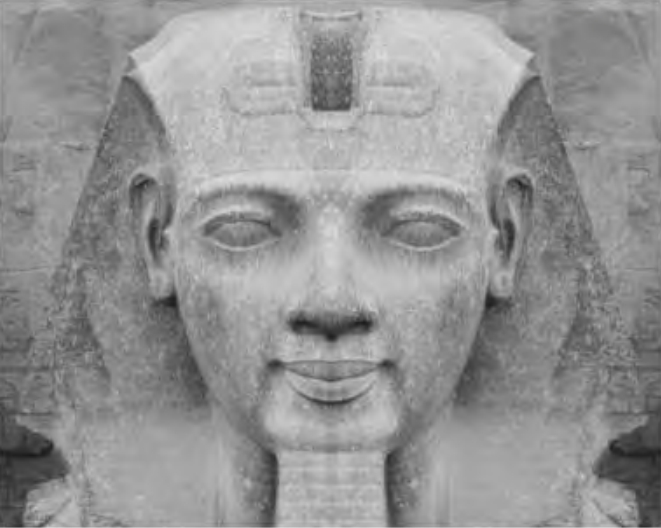

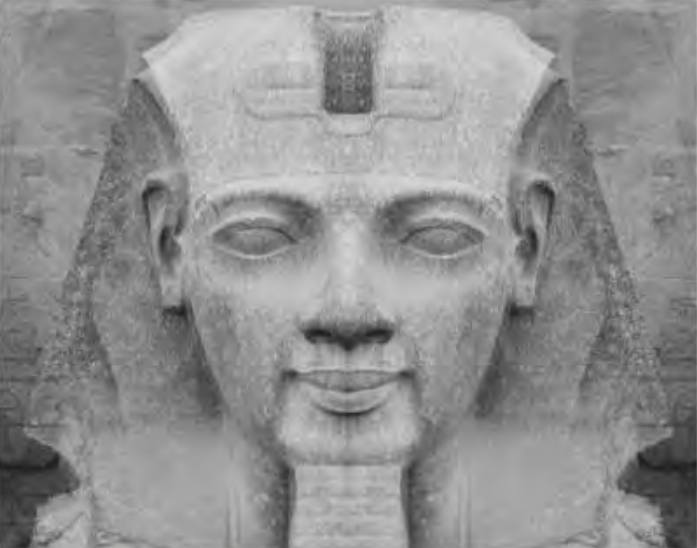

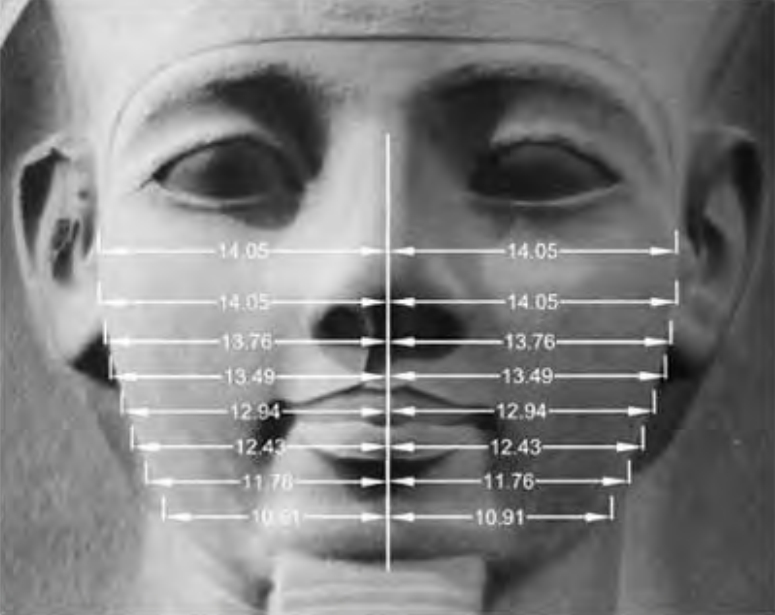

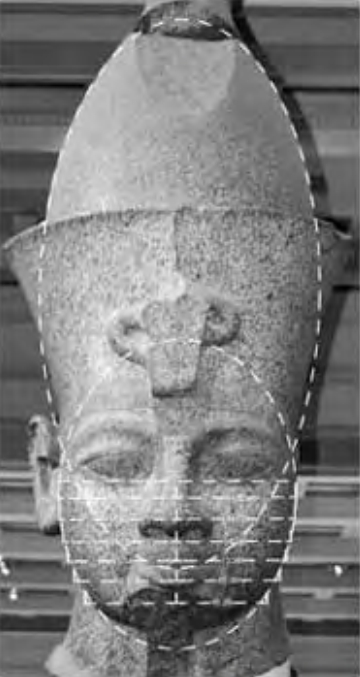

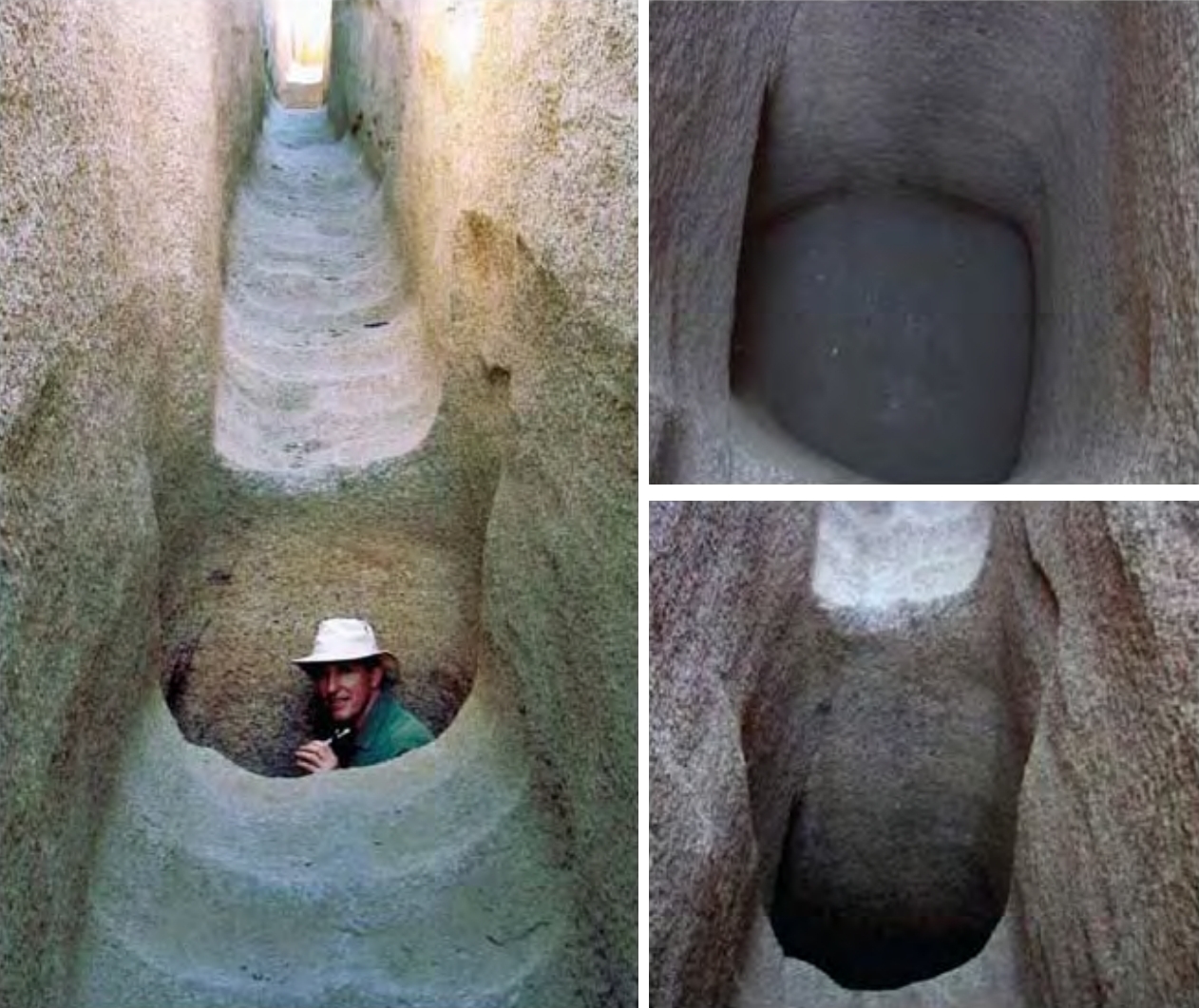

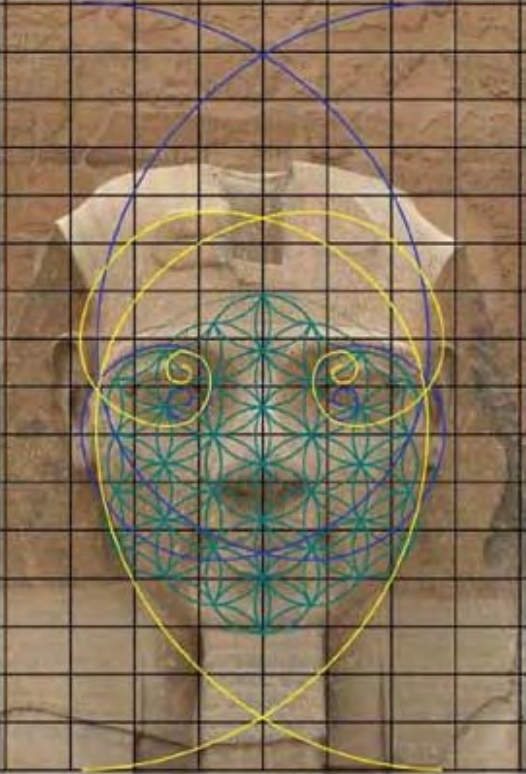

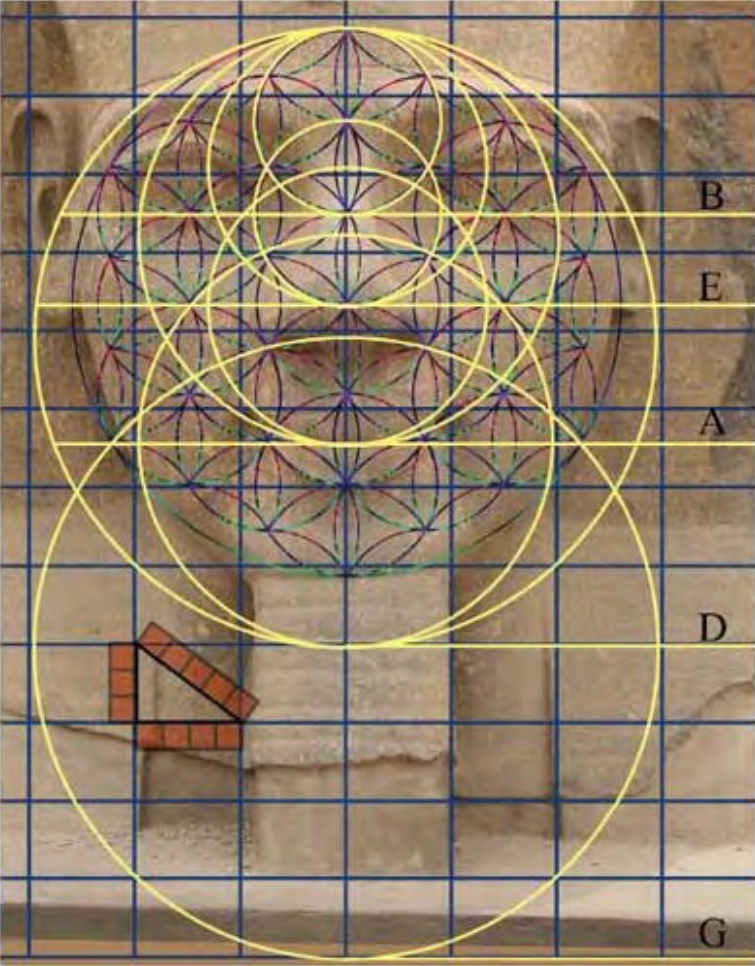

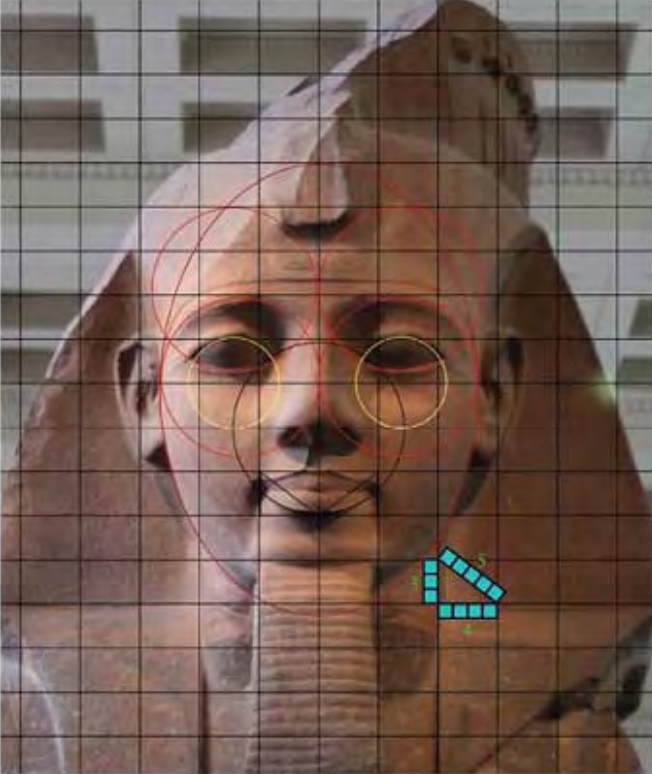

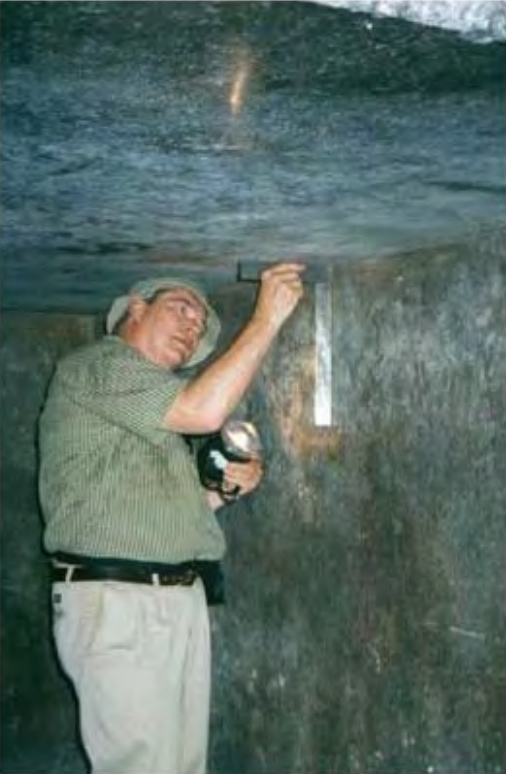

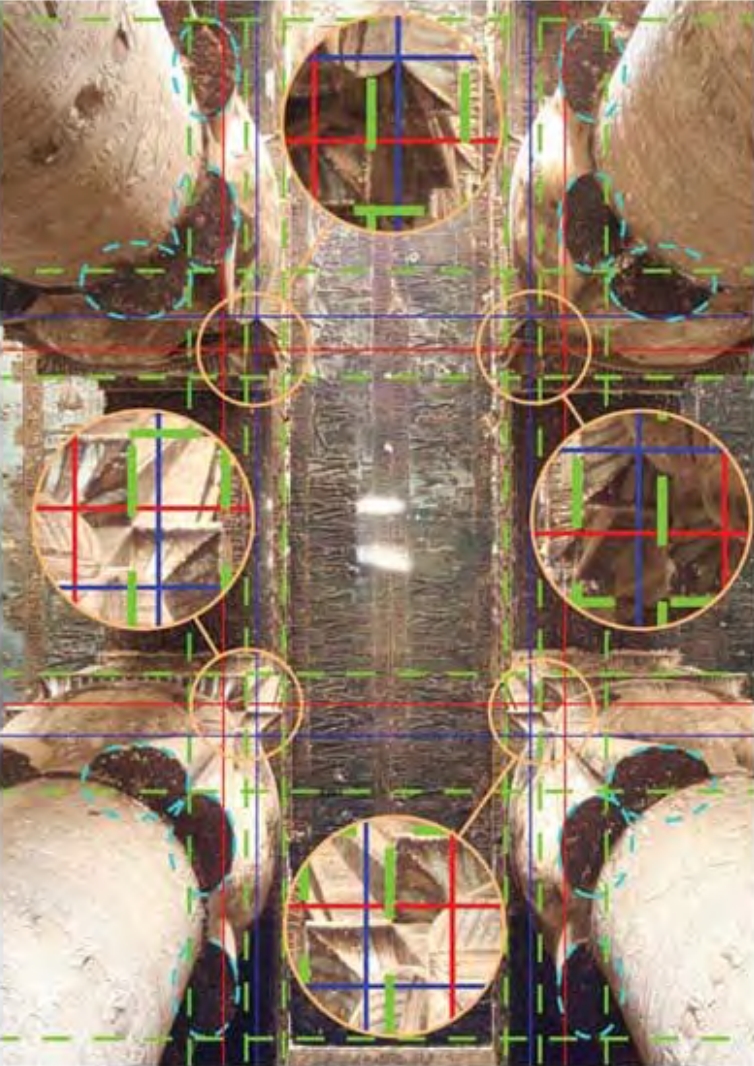

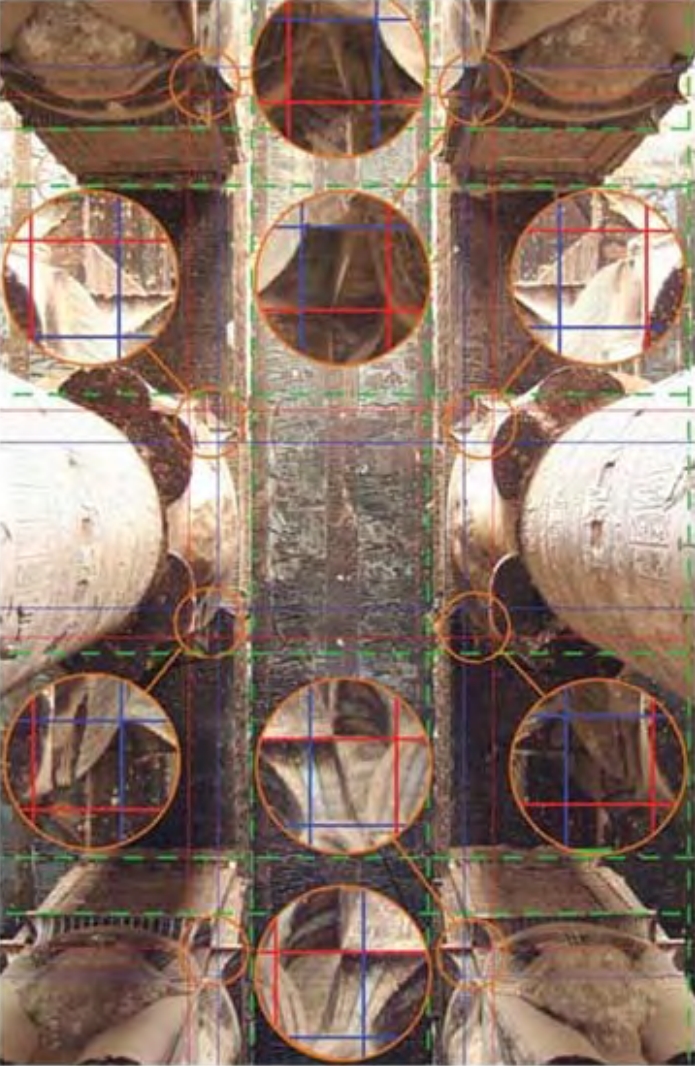

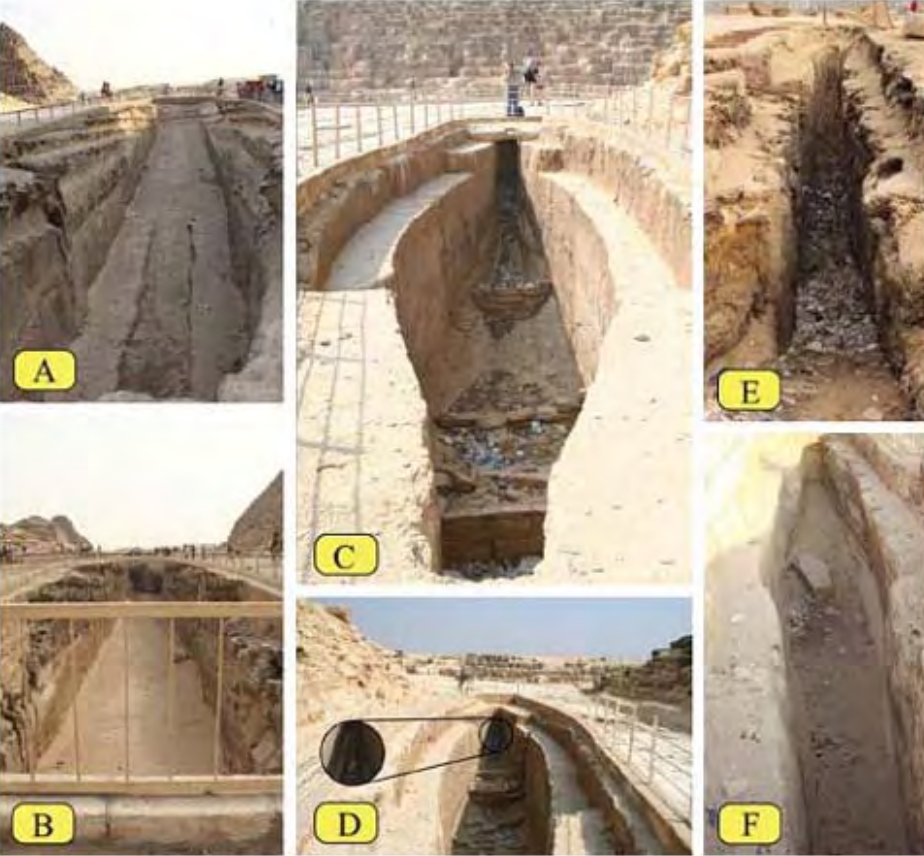

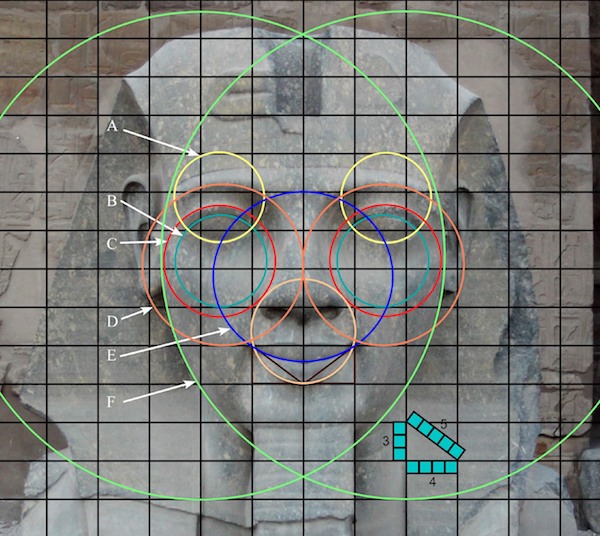

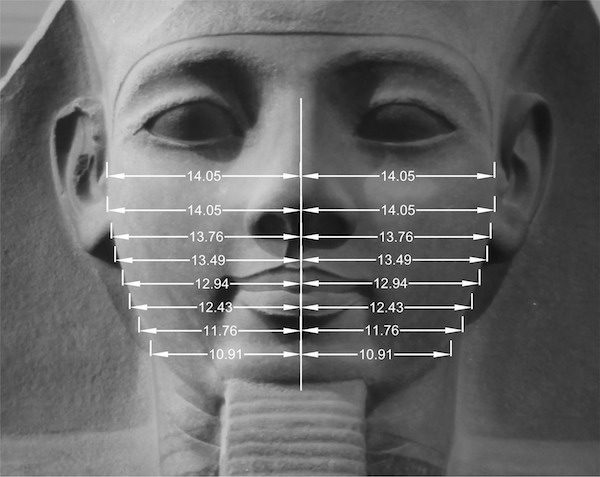

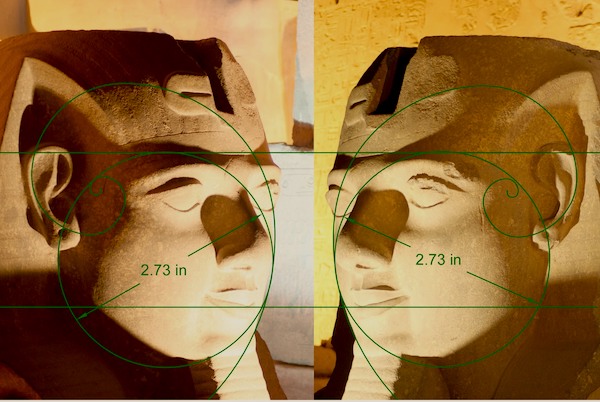

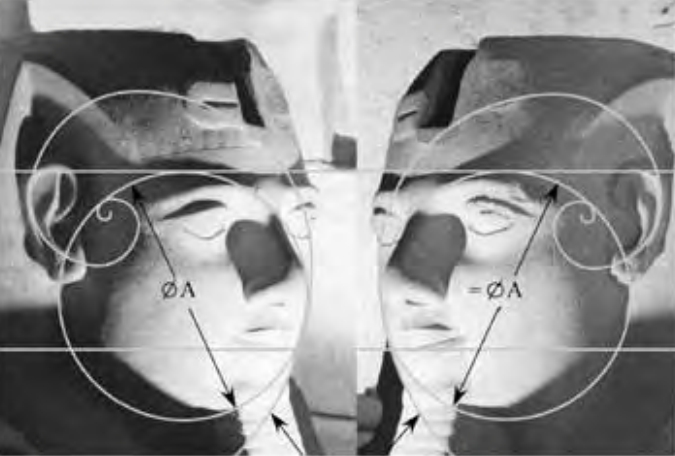

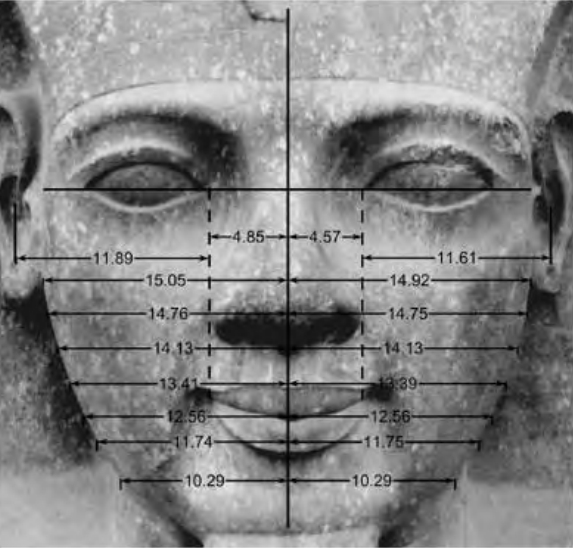

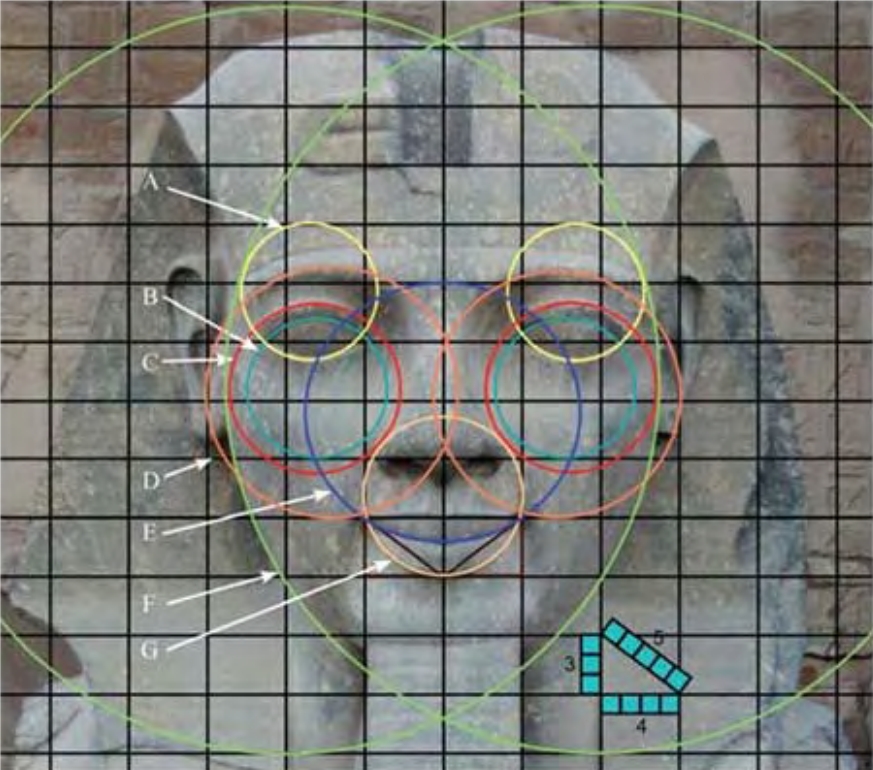

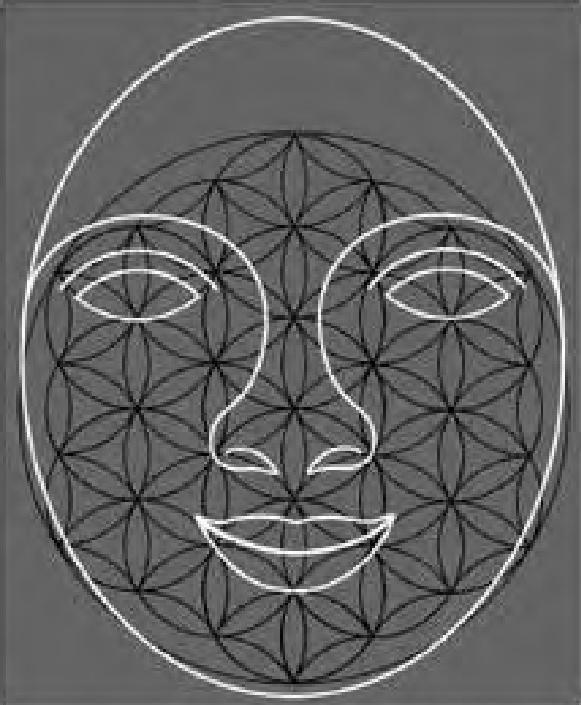

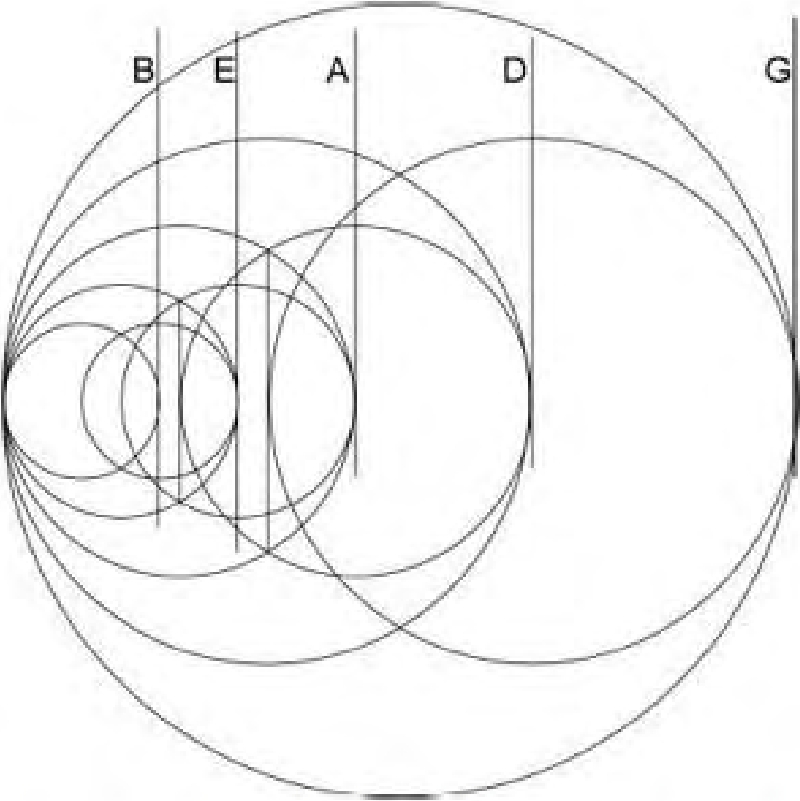

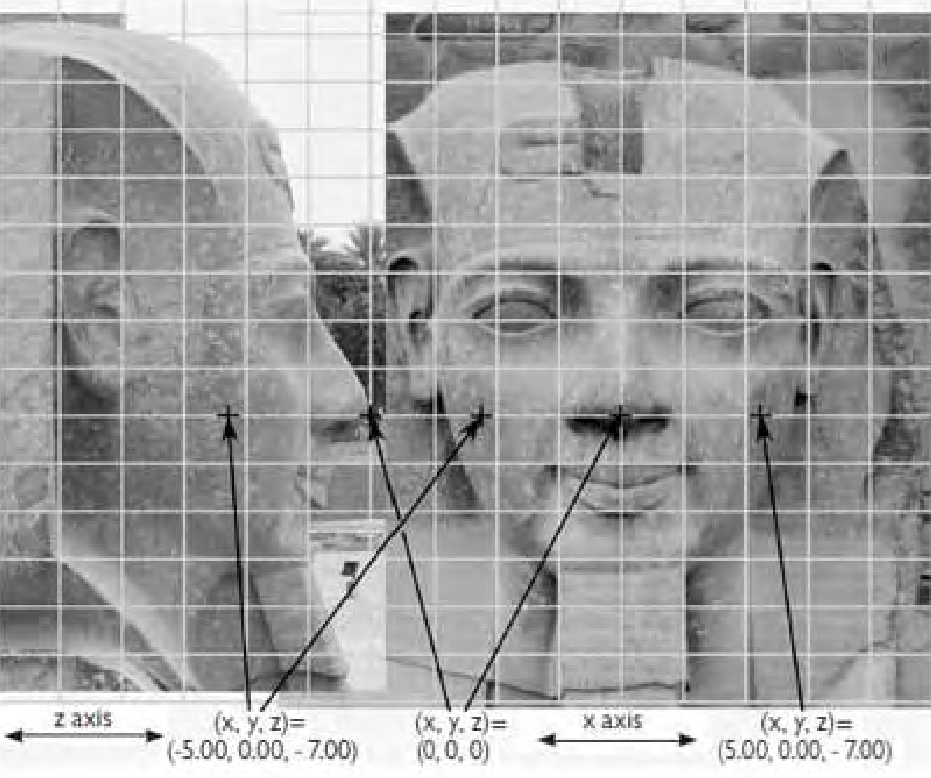

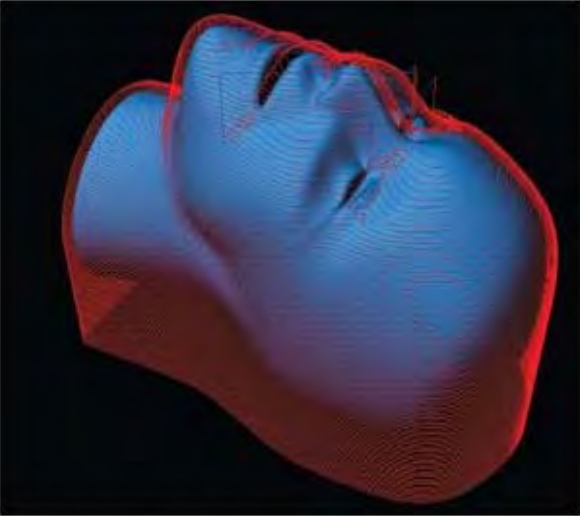

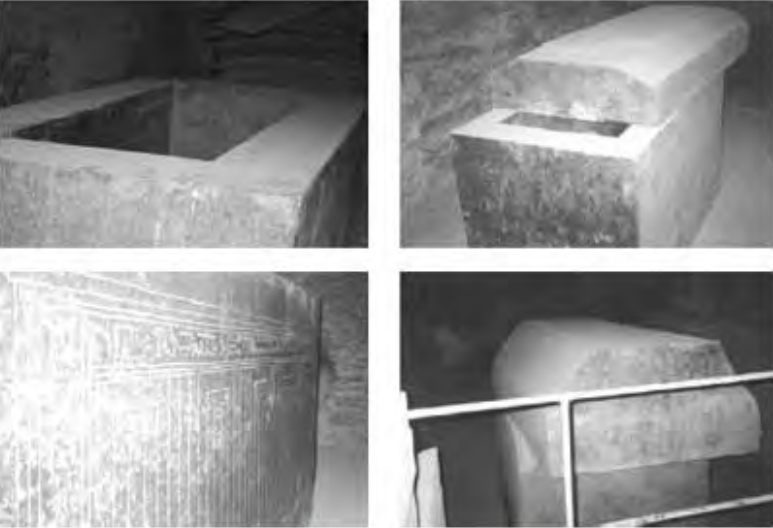

Using digital photography, computer-aided design software, and metrology instruments, Dunn exposes the extreme precision of these monuments and the type of advanced manufacturing expertise necessary to produce them. His computer analysis of the many statues of Ramses II reveals that the left and right sides of the faces are precise mirror images of each other, and his examination of the mysterious underground tunnels of the Serapeum illuminates the finest examples of precision engineering on the planet. Providing never-before-seen evidence in the form of more than 280 photographs, Dunn's research shows that while absent from the archaeological record, highly refined tools, techniques, and even megamachines must have been used in ancient Egypt.

CHRISTOPHER DUNN is a manufacturing engineer with 50 years of experience. He has worked primarily in aerospace with an emphasis on precision and laser application. He has published a dozen articles on his theories about ancient technology and is the author of The Giza Power Plant. He lives in Illinois.

| Reviews Forward Acknowledgments Introduction Chapter 1 ♦ The Shadows of Luxor Chapter 2 ♦ The Shadows of Ramses Chapter 3 ♦ The Ramses Challenge Chapter 4 ♦ The Shadows of Karnak Chapter 5 ♦ The Shadows of the Serapeum Chapter 6 ♦ The Shadow of the Sphinx Chapter 7 ♦ The Shadows of Denderah Chapter 8 ♦ Sticks and Stones: Tools of the Trade Chapter 9 ♦ In the Shadow of an Obelisk Chapter 10 ♦ In the Shadow of Egyptian Megamachines Chapter 11 ♦ Walking in the Shadow of William F. Petrie Chapter 12 ♦ Suspending Disbelief Bibliography |

iii iv v vi 1 12 22 32 40 49 58 69 72 82 97 107 117 |

“Christopher Dunn is an expert in his field. He knows a great deal about stone-cutting tools and has spent many years studying the ancient Egyptian monuments, sculptures, and artifacts. His findings are revolutionary. His word carries weight. If he is right, our perception of who the ancient Egyptians were may completely change. Read this book!”

— ROBERT BAUVAL, AUTHOR OF THE ORION MYSTERY, MESSAGE OF THE SPHINX AND THE EGYPT CODE

“Christopher Dunn’s painstaking work, literally, makes the ‘stones’ of the Egyptian gods speak. He provides profound archaeological evidence that shows an engineering consistency, suggesting an advanced intelligence, which understood the supreme science of sacred geometry. A must-read book for those who wish to understand the advancement of Egyptology in the world of today.”

– J. J. HURTAK, PH. D., AUTHOR OF THE BOOK OF KNOWLEDGE: THE KEYS OF ENOCH

“Utilizing almost 50 years of professional experience in engineering, manufacturing, tool-making, and space-age precision, Chris Dunn has provided an in-depth analysis of ancient Egyptian statuary, temples, and manufactured artifacts that has never been presented previously. This outstanding book, supremely well researched, amply illustrated, and complete with detailed photographs, will be cited as a major paradigm shift and reference source in the field for many years to come.”

– STEPHEN S. MEHLER, M. A., DIRECTOR OF RESEARCH, GREAT PYRAMID OF GIZA RESEARCH ASSOCIATION

“Admirers of Egyptian art and architecture are most fortunate that Christopher Dunn directs his experienced engineer’s eye toward the Egyptians’ ancient stonework. By noticing the most minute details he reveals sophisticated craftsmanship and immense significance for all areas of Egyptology. Mathematicians will appreciate the amazing three-dimensional geometry made manifest in very hard stone. Dunn points the way for geometers to uncover sharper, more accurate analyses of the proportions of Egyptian design. This book is an important contribution to scientific scholarship by showing how archaeology can firmly rest on a measurable foundation.”

– MICHAEL S. SCHNEIDER, AUTHOR OF A BEGINNERS GUIDE TO CONSTRUCTING THE UNIVERSE

“In this book, Christopher Dunn has brought to the field of Egyptology a new approach, which has been needed for decades. His ability as an engineer and master craftsman has given him the insight to discover ancient technologies and techniques that have been missed by traditional Egyptologists. This book is a paradigm change for the way of thinking about our ancient history and ancestors. I highly recommend this beautiful illustrated book to both academic and alternative researchers and for anyone interested in new ways of thinking about our ancient past.”

– JOHN DESALVO, PH.D., AUTHOR OF THE LOST ART OF ENOCHIAN MAGIC AND DIRECTOR OF THE GREAT PYRAMID OF GIZA RESEARCH ASSOCIATION

“As with Newton and the apple, Chris Dunn got a vision when visiting Egypt. His engineering background allowed him to unleash incredible facts, and thanks to this highly detailed book, we can now share the same marvels.”

– ALAIN HUBRECHT, ARCHITECT, WRITER, PROFESSOR, AND FOUNDER OF THE ASSOCIATION TRANSPERSONNELLE BELGE (ATB)

“If you want to see the precise high technologies ancient Egyptians really had, read this book. It is a serious donation to Egyptian legacy and an opus for the future of this planet.”

– ANTOINE GIGAL, AUTHOR, RESEARCHER, AND PRESIDENT OF GlZA FOR HUMANITY

“I believe, as Chris Dunn superbly details in this book, that ancient Egyptian sculptors and architects were so precise and their works so monumental that they must have used sophisticated technology, probably hidden in their time and now lost to ours.”

– MIKE LECKIE, STONE SCULPTOR

In the mid-1990s I was co-founder of a NASDAQ-listed software company in Albuquerque, New Mexico, which specialized in presenting digital data in a unique 3D immersive graphical environment (also called virtual reality, or VR). One particular time, we showed the results of our VR work to an undersecretary of the US Department of Transportation — an abstract presentation of rather mundane DOT traffic data from various road intersections around the nation. Because of the intuitive display system, without any interpretation training at all, the undersecretary was able to see patterns, anomalies, and trends in his data, striking evidence of unexpectedly massive distortions and errors, perhaps even fraud, resident in his measurements but unseen before.

So shocked was the bureaucrat that he told the audience of several hundred technophiles, “I will never be able to look at my new data the same way again. Not only that, I wont even be able to look at my old data the same way.” From this honest and open spontaneous reaction, I coined the saying, “A paradigm shift not only changes the future, it changes the past!”

What researcher Christopher Dunn has accomplished in Lost Technologies of Ancient Egypt and in his previous work, The Giza Power Plant, is more than a paradigm shift; it is more of a paradigm seismic event. Because once a person with a manufacturing or machining background — engineer, technician, machinist, artisan — reads and understands what Dunn has discovered and analyzed in ancient Egyptian stonework, that person will never look at ancient Egyptians the same way ever again. That reader will become skeptical of portrayals of ancient Egyptians as primitives in any sense. That reader will begin to analyze every new Egyptian archaeological discovery, to see what else conventional Egyptologists have overlooked. That reader will become part of the new paradigm.

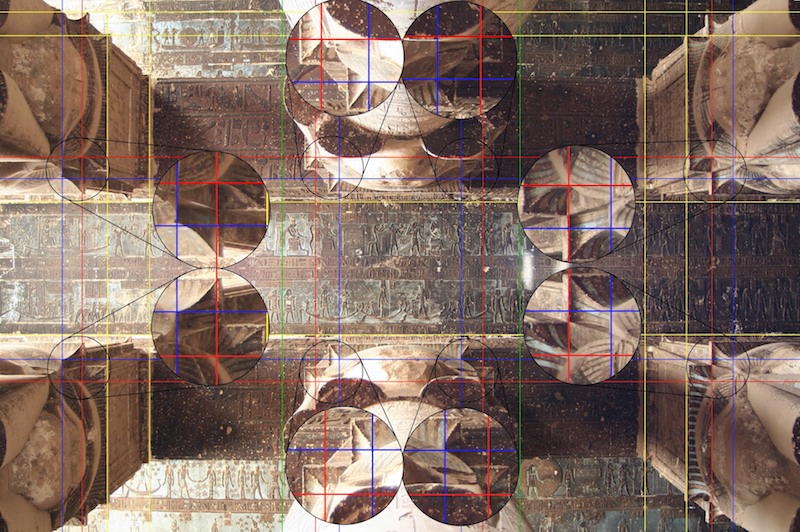

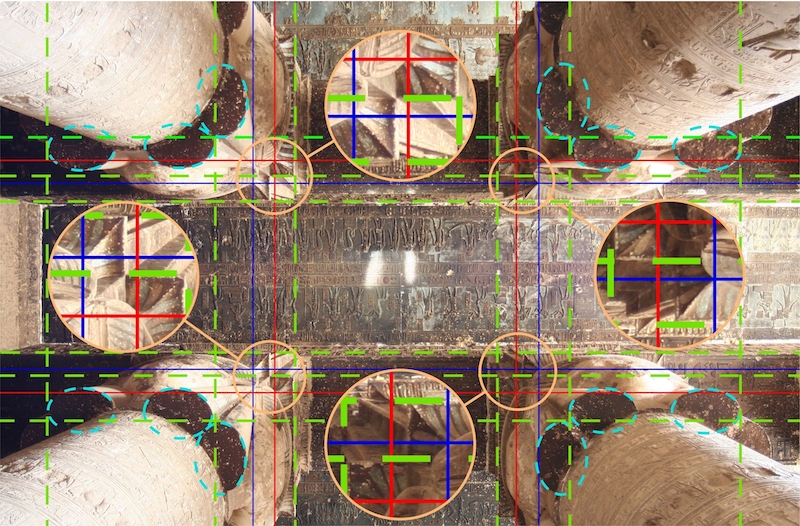

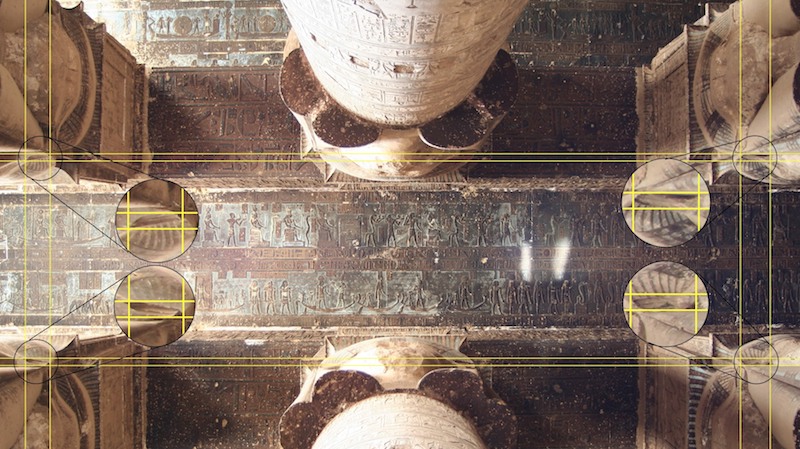

In these pages, Chris Dunn demonstrates an underlying system of incredible precision in the machining, layout, and positioning of both individual objects and groups of features, ranging from the toolmark details in the “Rose Red Rosetta Stone of Abu Roash” to the symmetries of the giant heads of Ramses at the temples in Luxor, to the layout of the column capitals of the Great Hypostyle Hall at Denderah, to the base of the Great Pyramid itself. Thanks to this work, the modern reader sits back in awe and admiration of the Egyptian geniuses of five thousand years ago. The ancient artifacts contain amazing messages, but the stones cannot speak for themselves. This book speaks for them.

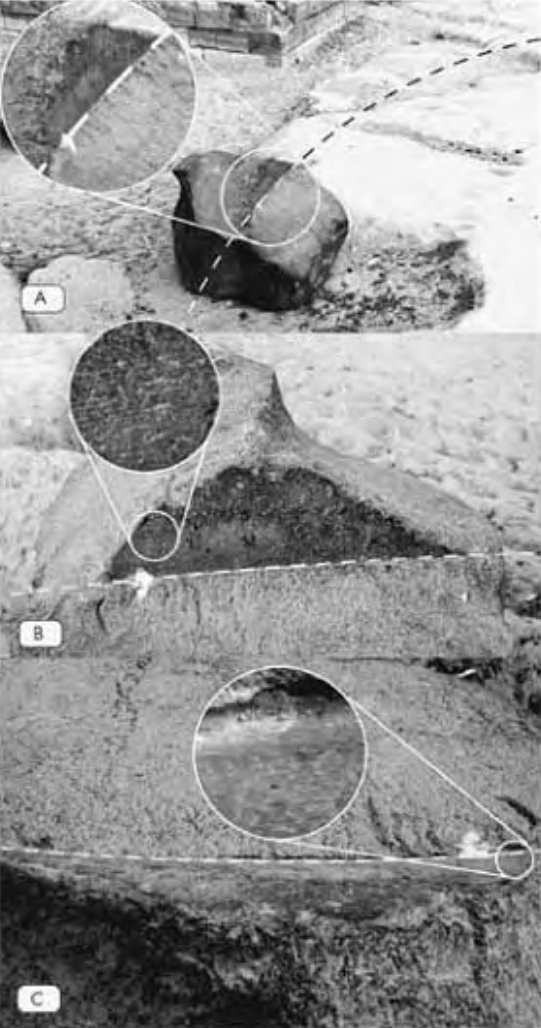

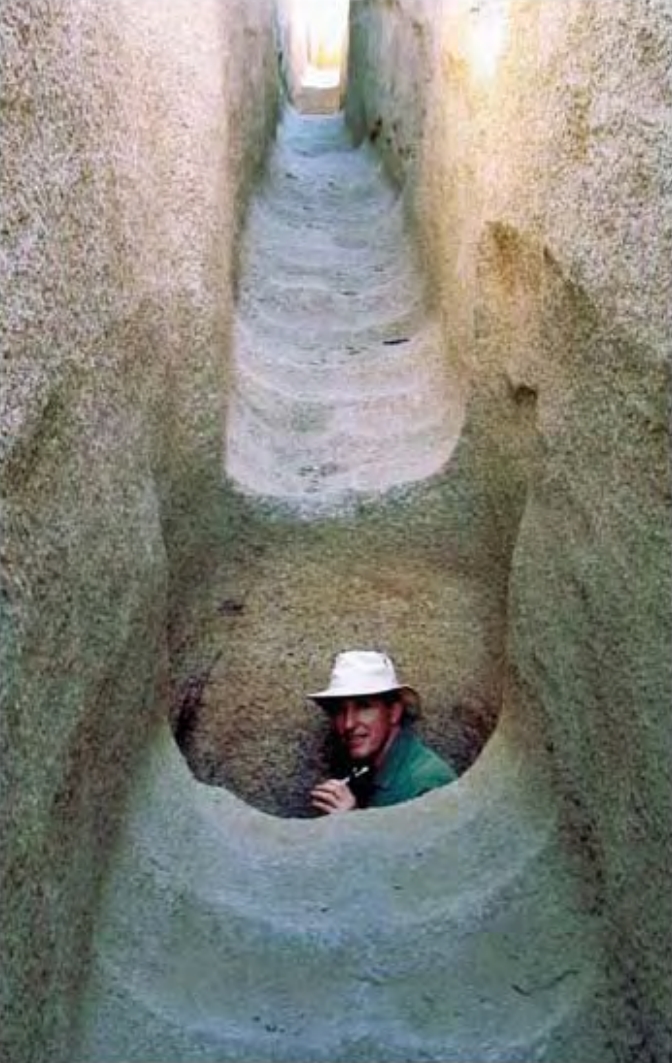

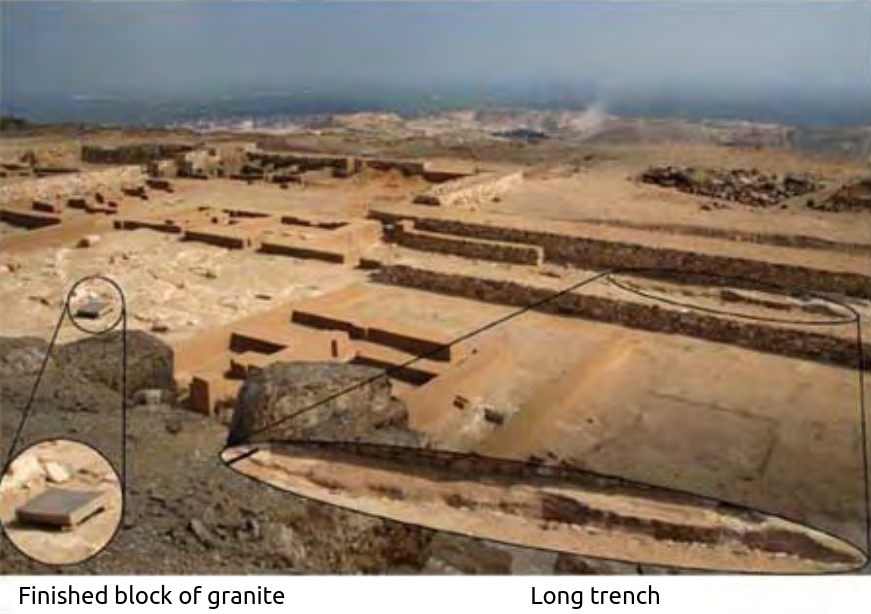

In November 2008, I accompanied Mr. Dunn and others to what some have called “the Lost Pyramid” at Abu Roash, some ten kilometers northwest of Giza. I was anxious to see the rose-colored granite piece that the author had described to me years before, anticipating seeing the compound radial cuts and distinguishing toolmarks. I was not disappointed. To any technophile, this one cut stone exhibits mute arguments against primitive tools and primitive peoples. More than any other artifact, it embodies an ancient “language” that still speaks to modern engineers. I immediately dubbed it the "Rose Red Rosetta Stone of Abu Roash.”

I called the stone a “Rosetta” because its discovery reminded me of another paradigm-changing artifact: in 1799, Napoleons soldiers found a curious object embedded in a wall of an Egyptian village. Their original report, “A Report on a Stone Found in the Village of Rosetta,” describes a black rock slab inscribed with three languages, one of them being ancient Greek, the others the unknown Egyptian hieroglyphic writing and the cursive or “demotic” Egyptian writing. Reading the Greek portion, the antiquarian Champollion was able to translate the names of the Pharaohs — written within cartouches — and thence the rest of the hieroglyphic writing itself. He opened up an eventual understanding of the millions of carved figures decorating the ancient temples and tombs of the Nile. Nobody would ever again look at the hieroglyphic carvings as mere magical, mystical figures, but would read the translations of experts who deciphered those cuts and reliefs, uncovering the lost history of Egypt.

The Rosetta stone thus facilitated a change in the worldview of moderns who looked back at ancient Egyptians. Nothing would ever be the same. I maintain that this book has accomplished a similar feat, every bit as meaningful to an understanding of ancient Egypt, if not more so. Once understood, Dunn’s discoveries will forever change the perception of the serious researcher.

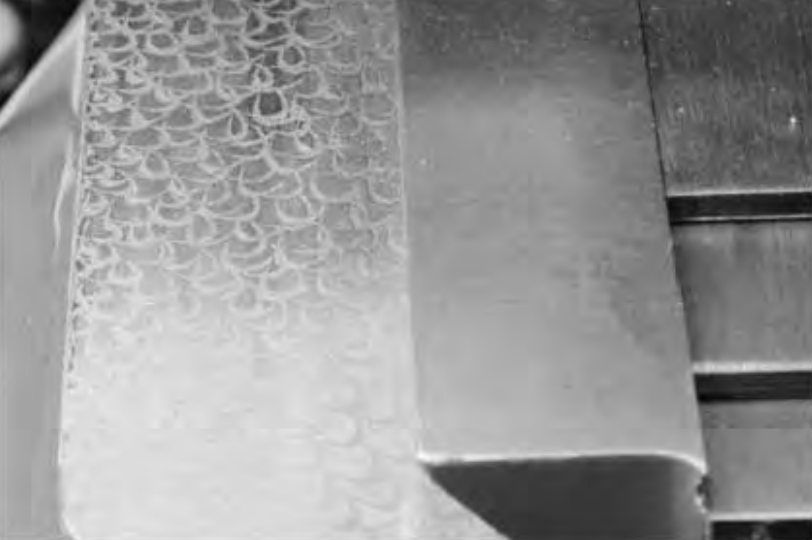

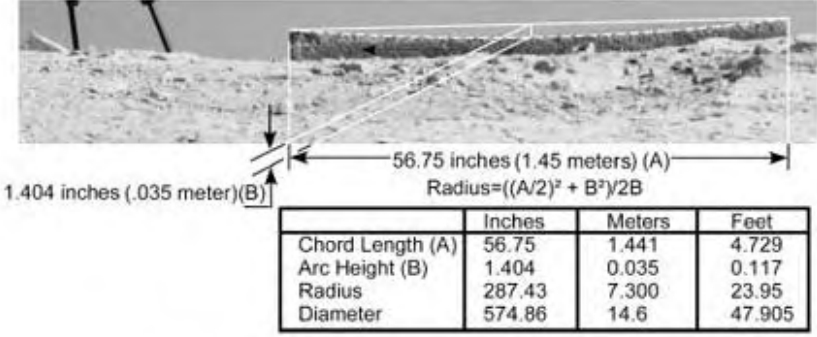

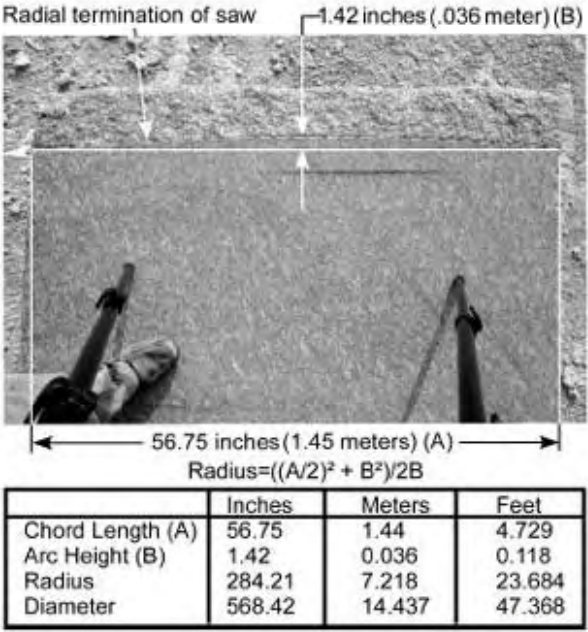

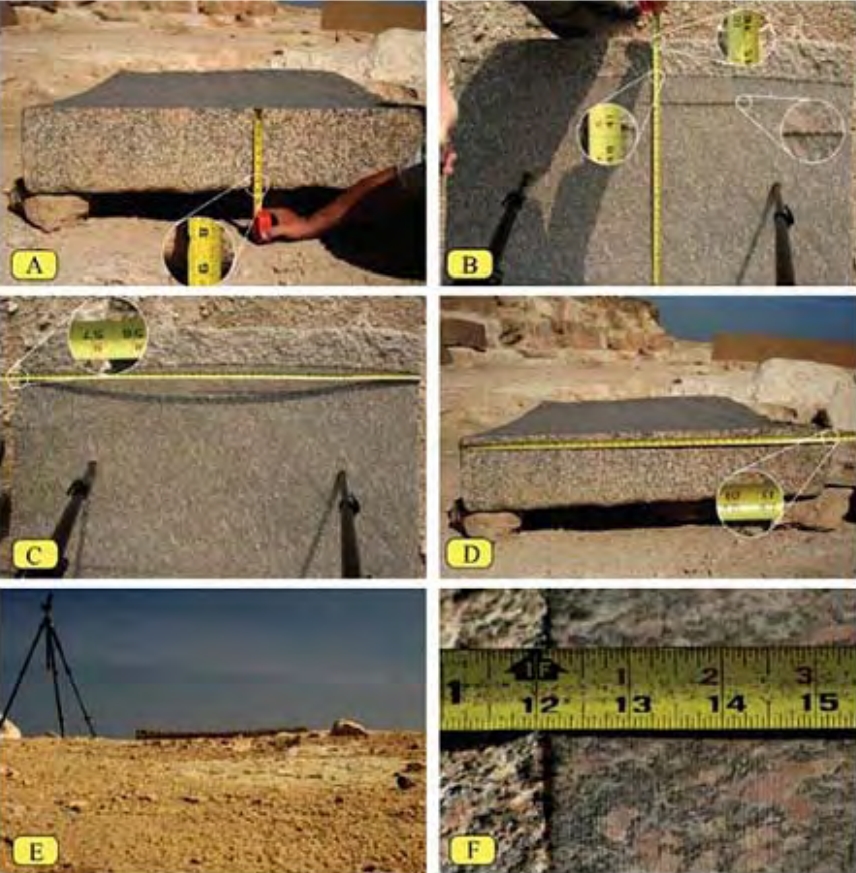

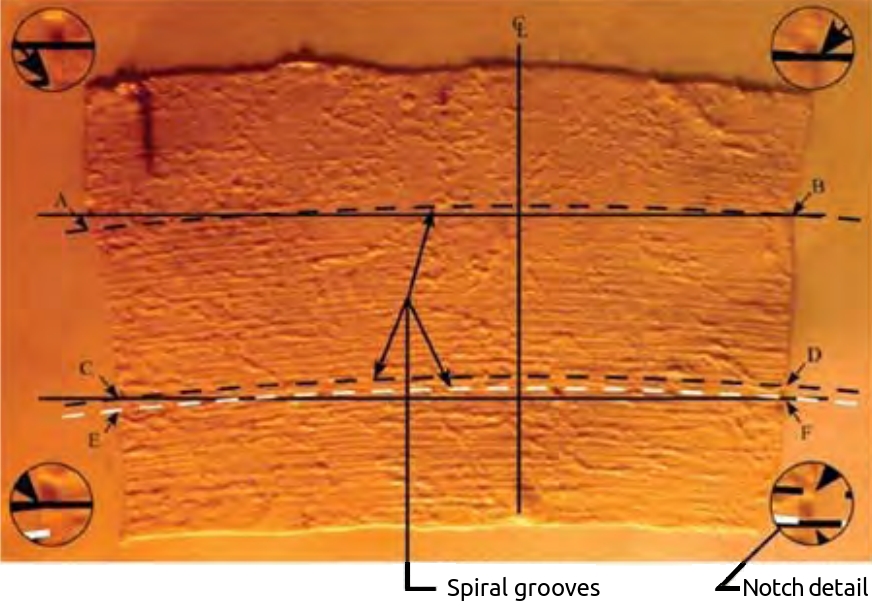

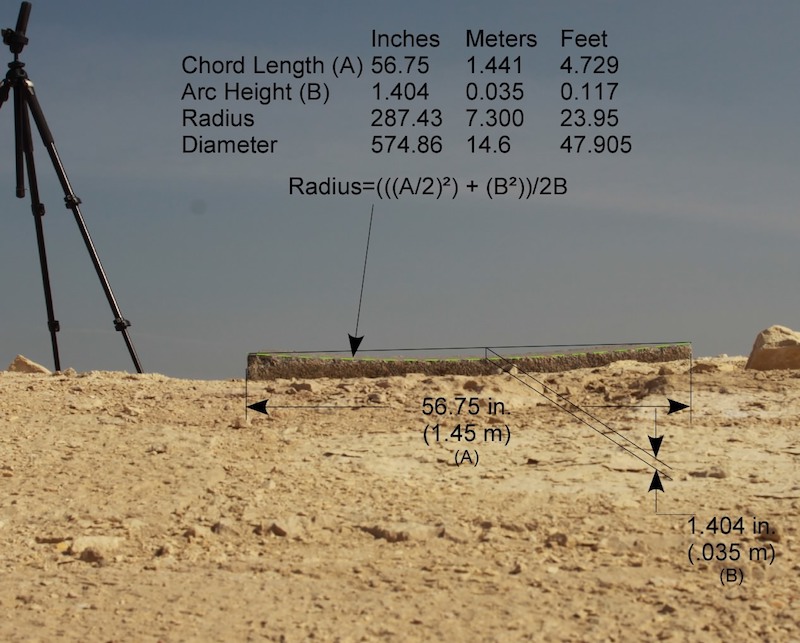

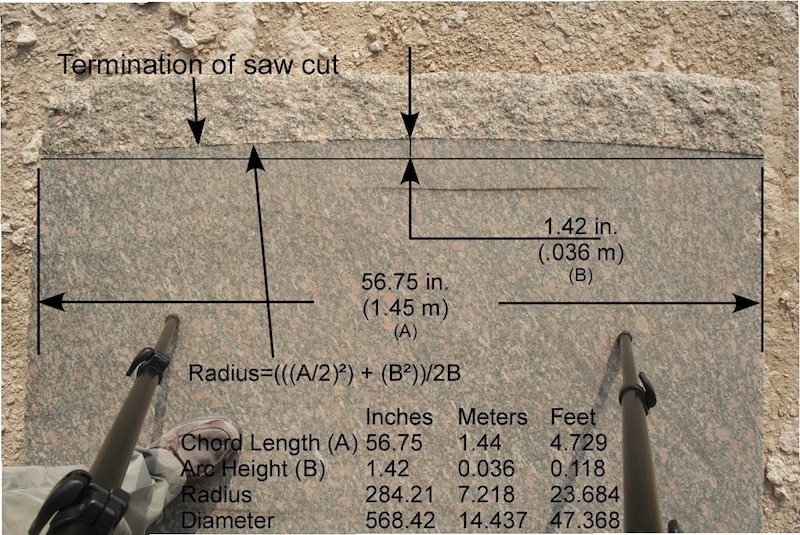

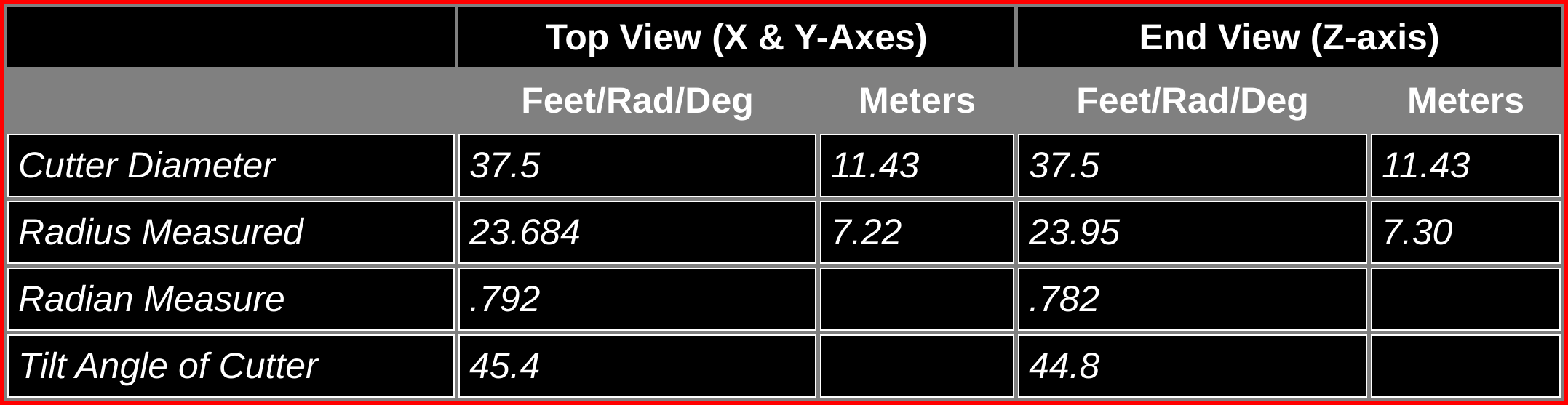

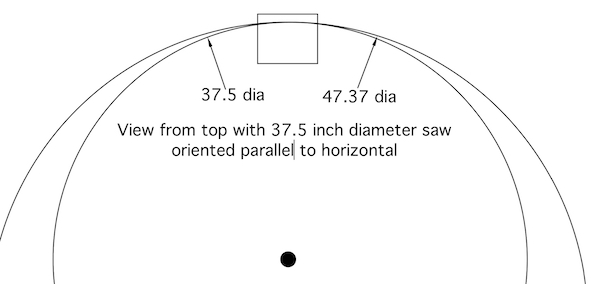

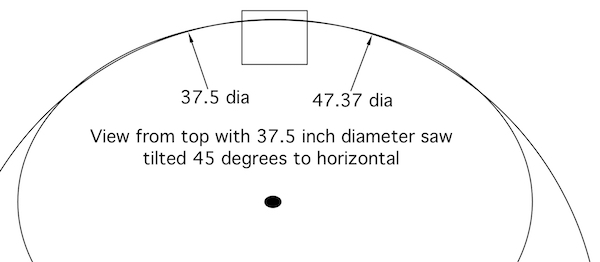

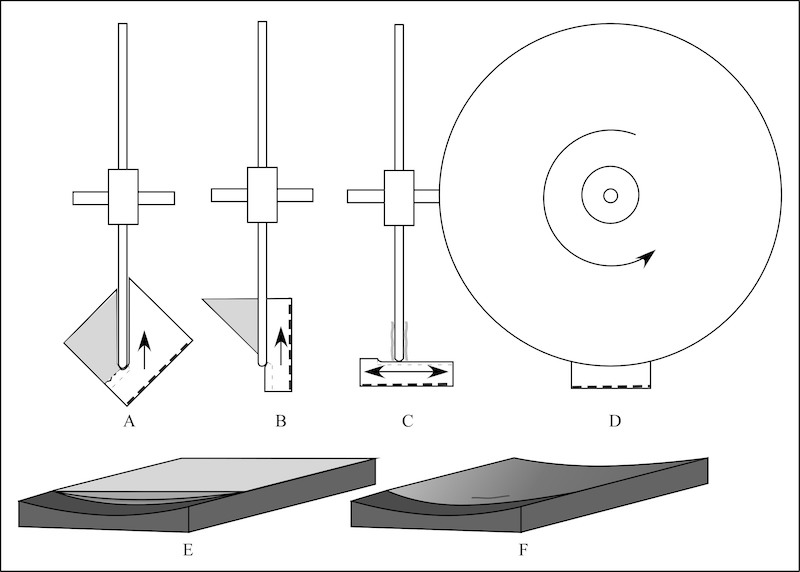

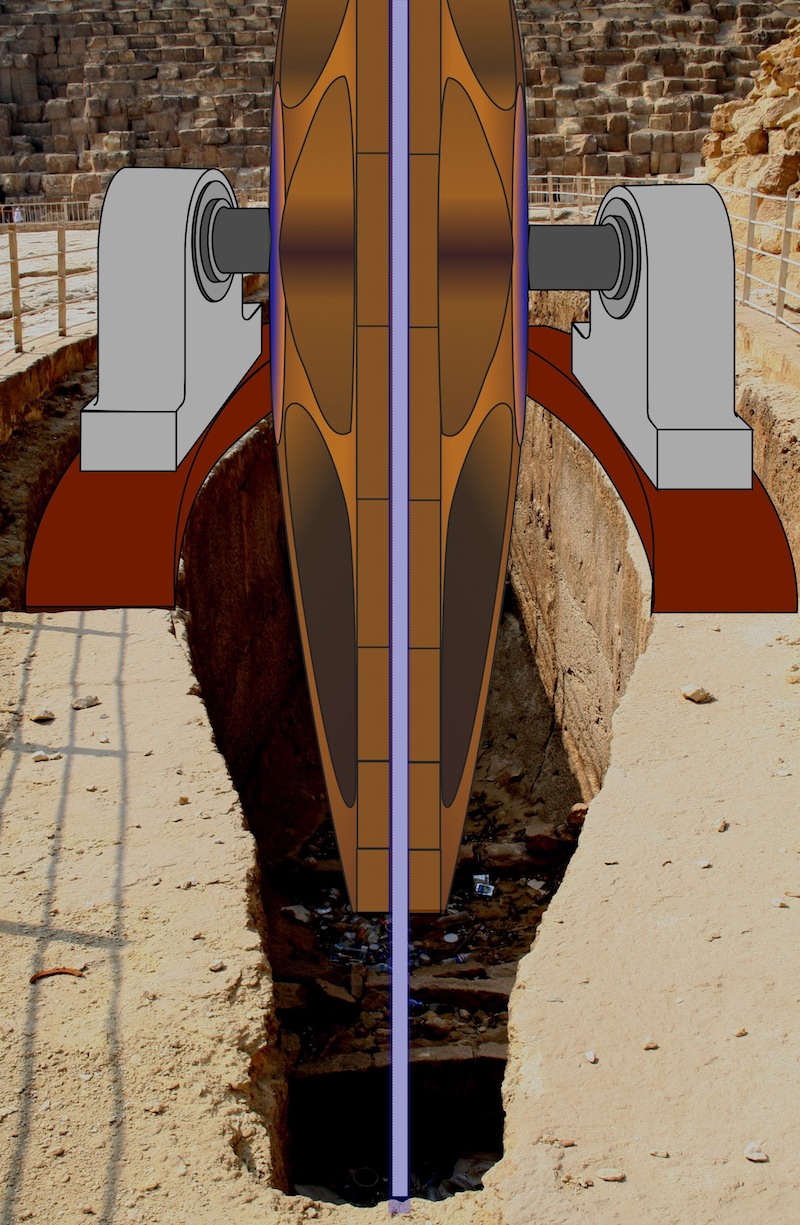

In a similar manner to Champollion reading ancient Greek and comparing it to the unknown hieroglyphic figures, researcher Christopher Dunn was able to “read” the machine-cut tool marks on the Abu Roash stone and compare them to those made by modern tools capable of the same operations. With years of experience and a trained eye for such details, and armed with the proper paradigmatic perspective, Dunn was able to recognize at once what it meant to produce a stone with a curved cut some 37 feet in diameter, and to reproduce that cut in small, uniform steps across a three-foot width — over 700 nearly identical radial tool cuts! This feat is simply not achievable by human hand alone, using any known tools.

Such toolmarks require at the very least a large saw blade or cutting tool, and sophisticated fixtures to produce the steps between cuts. To suggest that the primitive tools ascribed to the ancient Egyptians could have produced anything like these markings is ridiculous. In my opinion, this machined stone by itself demonstrates the existence of sophisticated tooling that did not exist again until the 1900s.

To the modern engineer, machinist, or toolmaker, the toolmarks on the Rose Red Rosetta Stone of Abu Roash are proof enough that the ancient Egyptians possessed technologies not replicated until the twentieth century — if even then. But Lost Technologies of Ancient Egypt shows more examples, each of which have similar impact — the Ramses heads in Luxor, the carvings and columns at Denderah — further reinforcing the genius of the ancient machinists, engineers, designers, and planners. Taken together, they represent arguments in stone that refute current Egyptological conclusions.

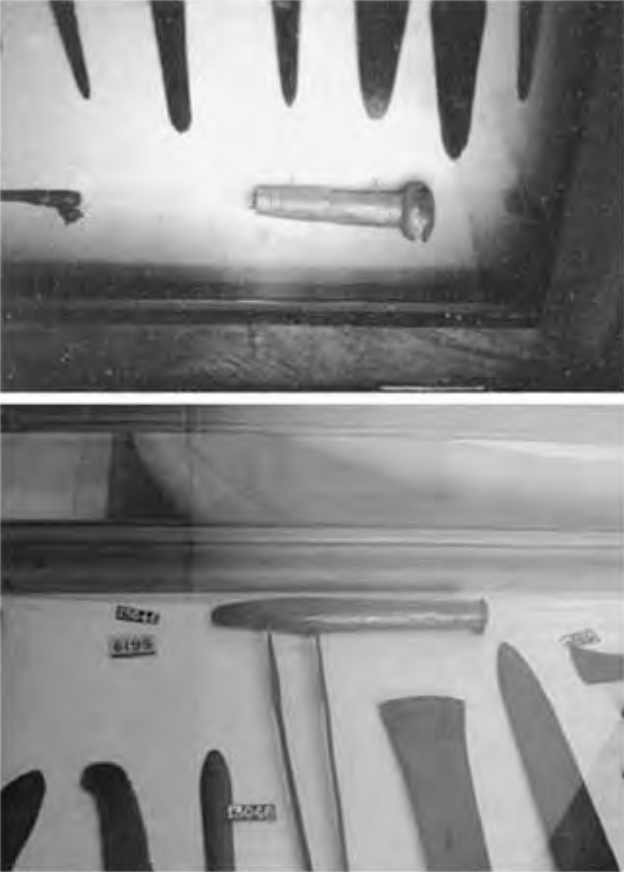

When civilization fails for any reason, metals of all kinds become precious commodities. They become knives, spear points, scrapers, fishhooks, even plows. Ancient Egypt underwent numerous upheavals caused by droughts, earthquakes, civil wars, religious strife, and foreign invasions. During the times of collapse, the advanced metal tools that the ancient Egyptians used were probably disassembled, cut apart, or melted down. What wasn’t immediately used would corrode and disappear after thousands of years. And perhaps some other advanced technology was also employed, the remnants of which we wouldn’t recognize today.

Large saw blades and other machine tools, if not secreted away from armies, earthquakes, floods, and mobs, would not endure very long. Over the millennia, few metal objects from our own time would survive or be recognizable. Life After People, a popular cable television show that debuted in 2009, shows example after example of the deterioration of manmade objects after years, merely because of lack of maintenance. In five thousand years, approximately the timespan estimated in Lost Technologies of Ancient Egypt, almost nothing of today’s technology would be left. In a world of resourceful (and destructive) human beings, the devastation would be much worse than Mother Nature alone could cause; marauding bandits and nomads would re-use, recycle, or otherwise destroy even our ubiquitous automobile engine blocks and our porcelain toilet bowls!

It may be that future archaeologists will one day uncover an untouched ancient factory or workshop under the sands or in the caves of Egypt, a place that was purposefully hidden away from destructive recycling, a place that would show us exactly what the ancients used and how. Such a discovery would be the equivalent of the unexpecedly sophisticated two-thousand-year-old Greek computational mechanism, the Antikythera Device! But to recognize their finds as evidence of ancient technologies, those future discoverers must have minds that are opened to the possibilities that Christopher Dunn has been the first to reveal. Otherwise, that advanced machine shop of the ancients could wind up stored in unnumbered boxes in the basement of the Egyptian Museum in Cairo, labeled merely as “funerary objects.”

Recent discoveries at the archaeological site Göebekli Tepe, in Turkey, indicate that twelve thousand to thirteen thousand years ago, so-called primitives were erecting T-shaped monuments as tall as six meters, ranging in weight from ten to fifty tons, perhaps building a Neolithic cathedral of sorts. Many of these stone pillars exhibit carvings of wildlife and even some human-shaped reliefs. For unknown reasons, the site was deliberately buried approximately ten thousand years ago. Because this site can be dated as existing prior to previously established dates for the beginnings of agriculture and urbanization, not to mention cooperative construction of stone monuments, we can readily believe that conventional chronology is at the least incomplete, if not wholly inaccurate. We see that every new archaeological discovery pushes back civilized development further and further into the past, never in the opposite direction.

So here we have evidence of moving massive stones and carving them in intricate detail dating earlier than 10,000 BCE — thousands of years before the ancient Egyptians were believed to have begun the stone machining that the author examines in this volume and in his previous works. Several thousand years passed between the time of Göebekli Tepe and that of the Egyptian First Dynasty, millennia in which artisans and engineers of ancient times could have perfected their craft, invented their complete suite of enabling tools and supportive technologies, and eventually emigrated to the Nile Valley, becoming part of the incipient civilization emerging there. With centuries of experiment and practice, those who worked in stone could have kept their knowledge secret, offering their finished products to leaders, priests, and the wealthy. As Dunn points out in this volume, even today trade secrets and proprietary knowledge are closely held, even in an educated world-wide civilization with widespread literacy and training. In ancient times the impulse to secrecy may have been even more necessary for survival.

Alas, the human beings who worked the Rose Red Rosetta Stone of Abu Roash, who machined the statues of Ramses, the columns of Denderah and the stones of the pyramids, were more fragile and evanescent than the mighty tools they employed in their work. If tools of metal are lost in war or natural catastrophe, their flesh and blood designers and operators are even more subject to the vagaries of Fate — disease, injury, wounds, and famine can take away technicians, inventors, planners, and managers, while leaving behind marvelous tools fit only for destruction by desperate people ignorant of their value.

If the knowledge of a specific task, the operation of a given machine tool, or the procedure for laying out vast projects is resident in just a few people, maybe just one, then the loss of that person or group means the knowledge is gone forever, unless it is recorded. This is an eternal problem, not limited to the ancient Egyptians of five thousand years ago. As a modern example, in 1992 while working at the White House Science Office, I invited to a meeting there a person from the National Science Foundation. Although only peripheral to the agenda, this older scientist regaled us with a tale of a lost technology of modern times, namely how to start up the engines of the Saturn V rocket that took American astronauts to the Moon from 1969 to 1972. Incredibly, this leading scientist averred that no one was alive who knew how to start up the engines on the largest rocket ever flown. No one had written down the standard operating procedure, and the rocket men who had developed the technique had all passed away.

So in 1992 CE or 1992 BCE or further back in time, we can find sufficient examples to demonstrate that technologies are not always lost as a result of conspiracy. Ordinary human pride, greed, stubbornness, selfishness, and even carelessness, can account for much of our loss.

In two groundbreaking works, author Christopher Dunn has opened our eyes that ancient Egyptians, and maybe others in the past, designed, planned, laid out, and precisely machined stone statues that would be difficult to reproduce even with todays manufacturing technologies. As the first person to uncover and develop this new paradigm, he has gone on to investigate other ancient Egyptian artifacts, temples, tombs, and pyramids using this new way of looking at information. He has retrieved knowledge that all before him have overlooked, save Flinders Petrie, whose interest was not primarily proving advanced ancient technology, merely commenting upon interesting findings. A new way of looking at old data could bring new respect to ancient civilizations that left magnificent ruins in a still-troubled part of the world. As we understand more about the origin of Egyptian temples and pyramids, we find a way to bridge the past and the present, a way to look for still other revelations that affect us as human beings.

Arlan Andrews Sr., SCD

Arlan Andrews Sr., a registered Professional Engineer, graduated from New Mexico State University with a doctorate in mechanical engineering. Throughout his career he worked as a missile tracker at White Sands Missile Range, as a member of technical staff at Bell Telephone Laboratories, as the advanced manufacturing initiatives manager at Sandia National Laboratory, and as the environmental director at the Naval Air Station, Corpus Christi, Texas. In 1991, Dr. Andrews was assigned to the Technology Administration of the U.S. Department of Commerce as a Fellow for the American Society of Mechanical Engineers (ASME). Following his tenure there, he became an ASME Fellow at the White House Science Office. He later co-founded several high-tech startup companies, one of which was listed on NASDAQ and another still operating in North Carolina. He also founded the nonprofit futurist organization SIGMA, a group of professional scientists and science fiction writers formed to advise the Federal Government on future technologies and events.

|

No one can be a great thinker who does not recognize that as a thinker it is his first duty to follow his intellect to whatever conclusions it may lead. Truth gains more even by the errors of one who, with due study, and preparation, thinks for himself, than by the true opinions of those who only hold them because they do not suffer themselves to think. – JOHN STUART MILL, ON LIBERTY |

As a lawyer trained in the areas of evidence and the nature of proof, I have witnessed firsthand the disagreements that occur in the arena of ideas. Sometimes these disagreements make their way into a courtroom, where a trial is held and a judgment made as to which opinion carries the weight of evidence — evidence that ultimately convinces a judge and jury. The court reaches a decision in favor of the party or parties that presented that convincing evidence.

Over the course of this book, Chris Dunn presents evidence that raises a multitude of challenging questions, introducing new ideas and opinions about the history of craftsmanship in Egypt. This work calls into question established paradigms and theories that have, for many decades, formed the basis of academic studies in schools and universities around the globe and in volumes that occupy the shelves of virtually every library. But first, let me describe how I came to be involved in this debate.

Leaving the formal practice of law in the late 1980s, I have, in the ensuing two decades, become a manufacturer, more specifically a fabricator of sheet metal components for gas turbine engines at Danville Metal Stamping Co., Inc., located in Danville, Illinois, USA. It was here that I first met Dunn, upon my arrival at Danville Metal in 1988. He preceded me at the company by a couple of years and was then serving in the capacity of laser engineer. He later became a manufacturing engineer and, in 1995, brought his manufacturing and engineering skills, as well as his judgment and insight, to the post of Human Resources Manager. As President and CEO, I devote a significant amount of time to human resources and, consequently, my contact with Dunn increased dramatically.

At that time, I had little background or particular interest in Egypt, the pyramids, or ancient technologies and civilizations. Nonetheless, like most humans, I had a natural curiosity about how things are made or done and why. My curiosity then turned toward the subject that Dunn had spent the past twenty years studying in his spare time, and I was impressed by the enthusiasm and sense of wonder he had for it.

Over breakfast after a Sunday walk, Dunn would discuss his thoughts on ancient technologies. Those discussions were often supplemented by a photograph or other visual aid, such as an engineering drawing or a sketch on a napkin or scrap of paper. We would also discuss the online controversies that swirled around his comments, theories, and questions raised in his first book, The Giza Power Plant. Dunn’s analysis did not stop there; he instead applied the criticism he received to improve his methods and collect further evidence.

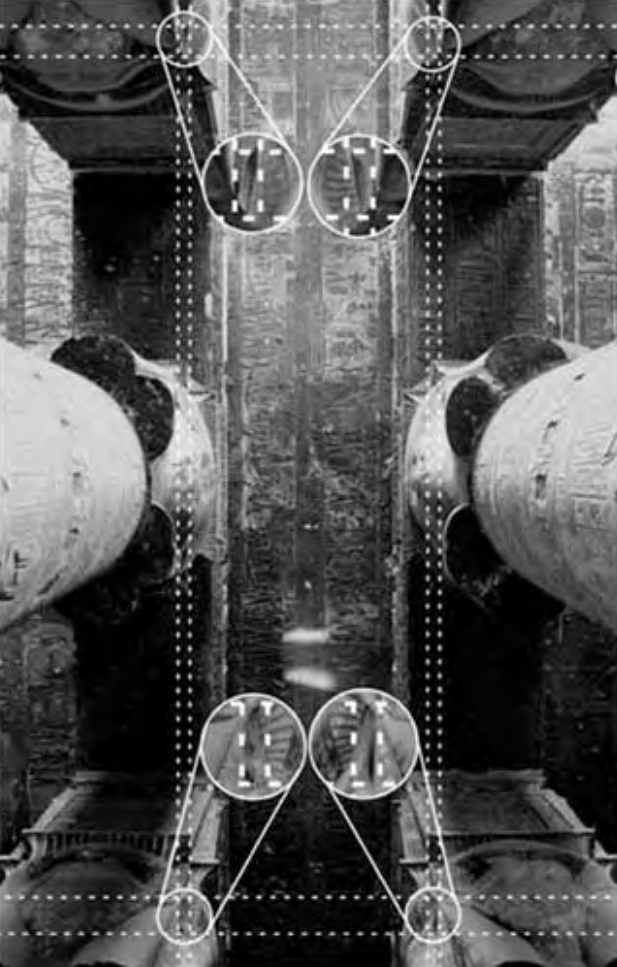

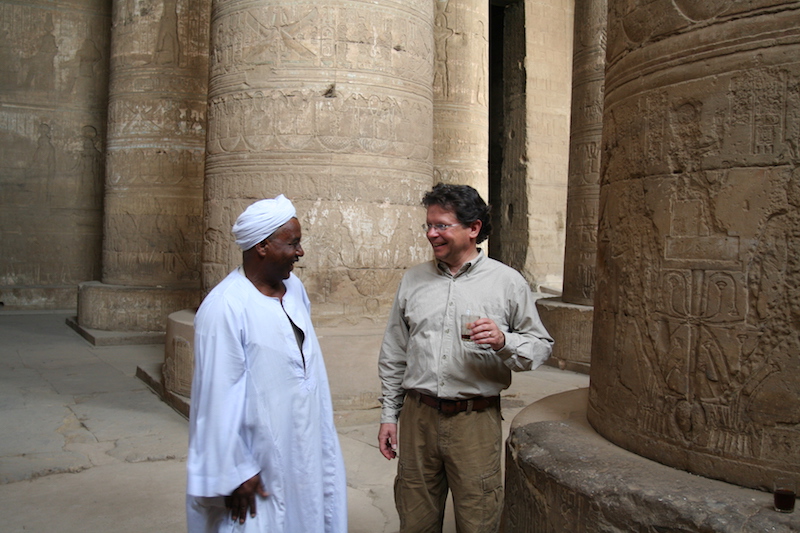

In February of 2006, Dunn took another of his many trips to Egypt, this time with a tour group that visited a number of temples in Upper Egypt. Although he had first visited those temples in 2004, his exposure had been brief and he was interested in more closely inspecting temple artifacts, especially in the Luxor Temple. This new expedition took Dunn deeper into and beyond the issues he had explored previously. He returned from the trip with a new and elevated interest in the accomplishments of the ancient Egyptians in the temples, particularly the statuary. His observations in the temples presented a new frontier of amazing feats, raising questions that were complementary to observations he had made in connection with granite boxes and other aspects of construction in the pyramids.

In April and May of the same year, I took the opportunity to travel with Dunn to witness in person what I had only examined as photographic evidence. This included many looks through the viewfinder of his camera equipped with a telephoto lens and then verifying the results captured by the camera.

From personal observation, I can verify that in this book Dunn has been true to the evidence he observed. As an engineer, Dunn was able to analyze his observations with CAD/CAM programs and geometrical analysis unavailable or incomprehensible to the average observer. Among other things, with advances in digital imaging, a technology used daily in manufacturing, his computer-assisted analysis afforded him the ability to see attributes that could not be seen or analyzed with the naked eye even in the presence of the original artifact.

Using his extensive skills and his tools as an engineer and a toolmaker and bringing to bear his decades of experience in manufacturing, Dunn was relentless in assessing what he could reach and, through his camera lenses, preserving that which he saw. He also used his camera to capture what he could not necessarily reach and was thoughtful and creative in his approach. As the reader will witness in the pages that follow, Dunn thinks well in three dimensions and understands thoroughly the consequences of a particular test, comparison, or view.

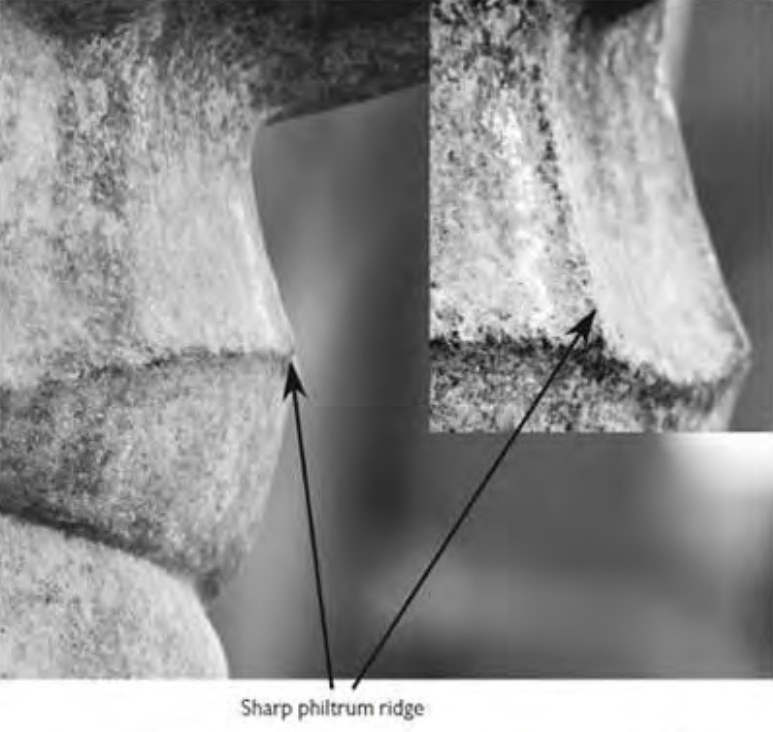

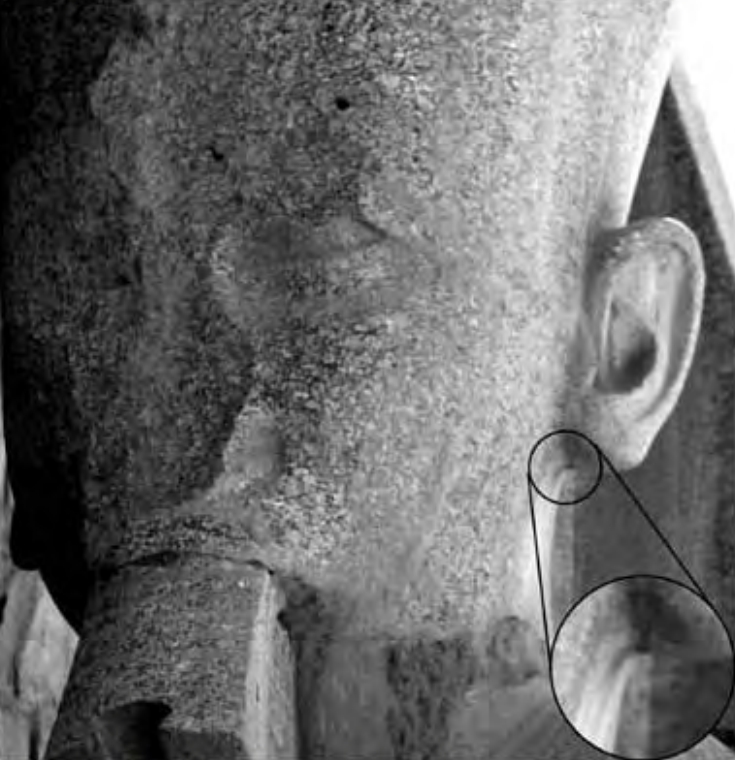

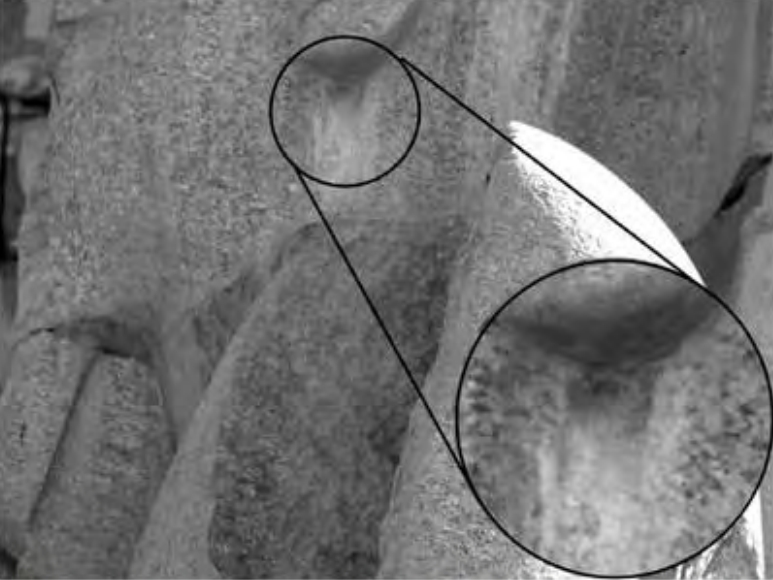

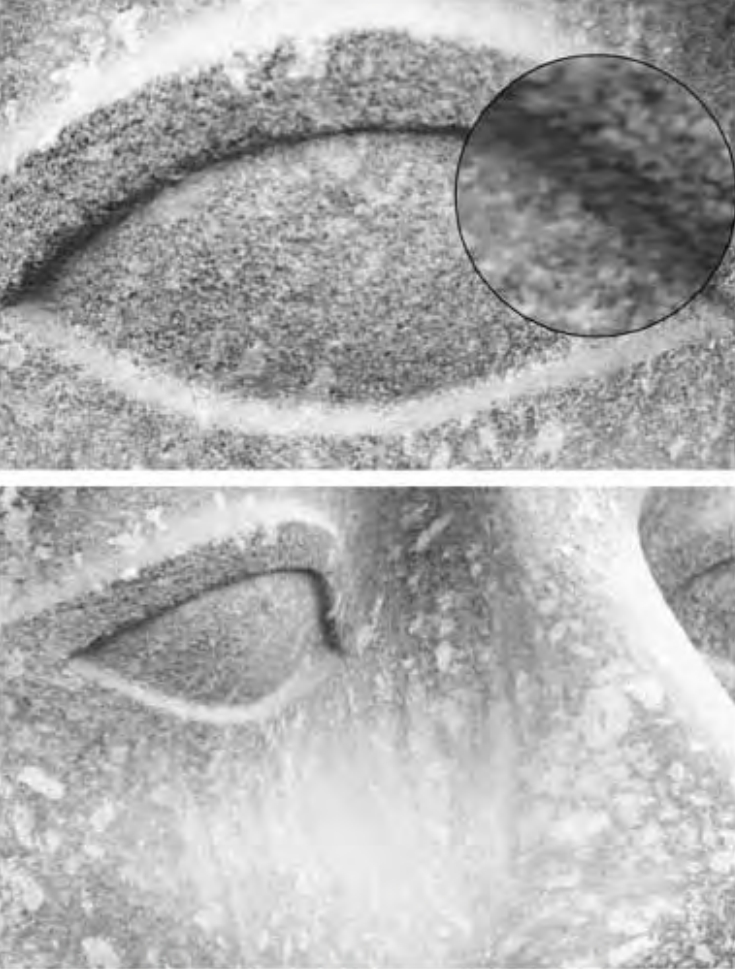

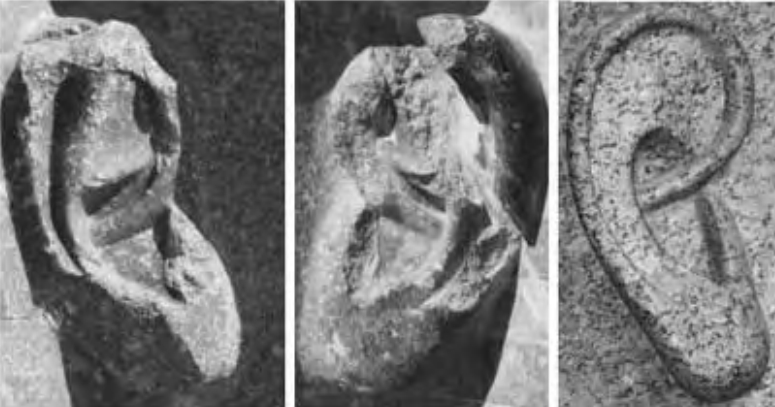

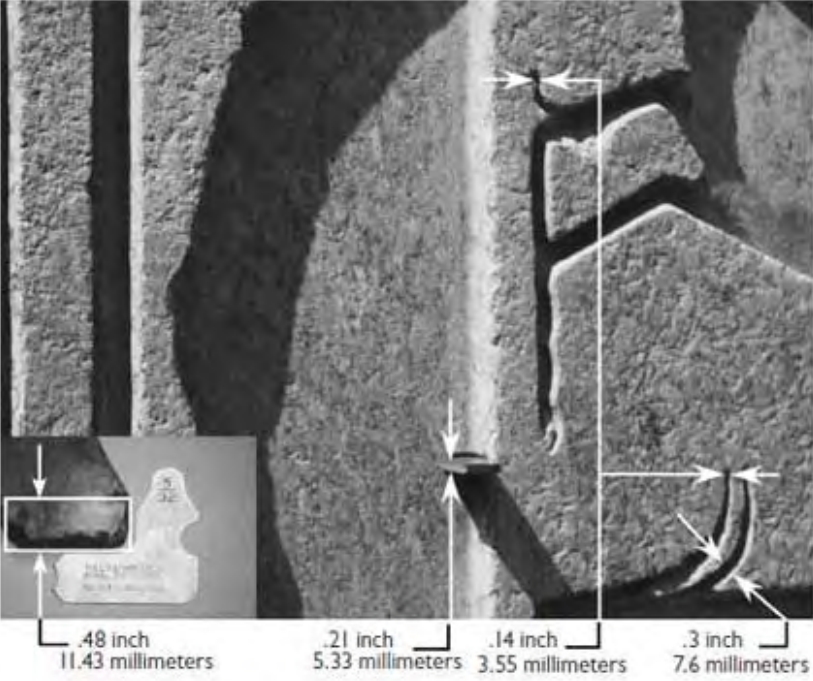

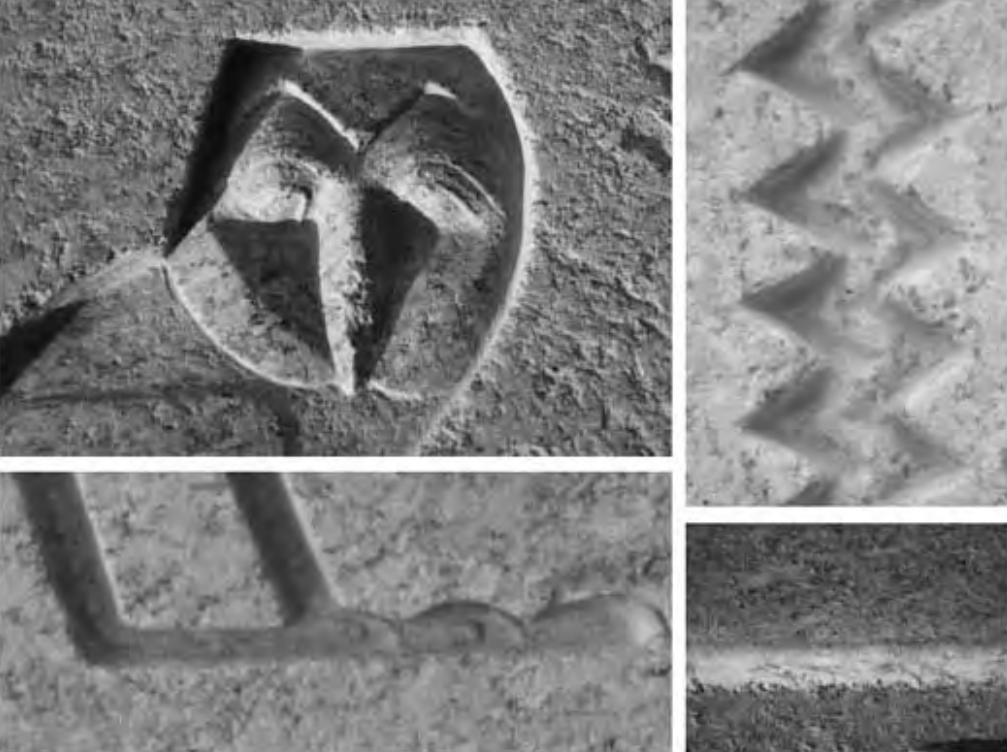

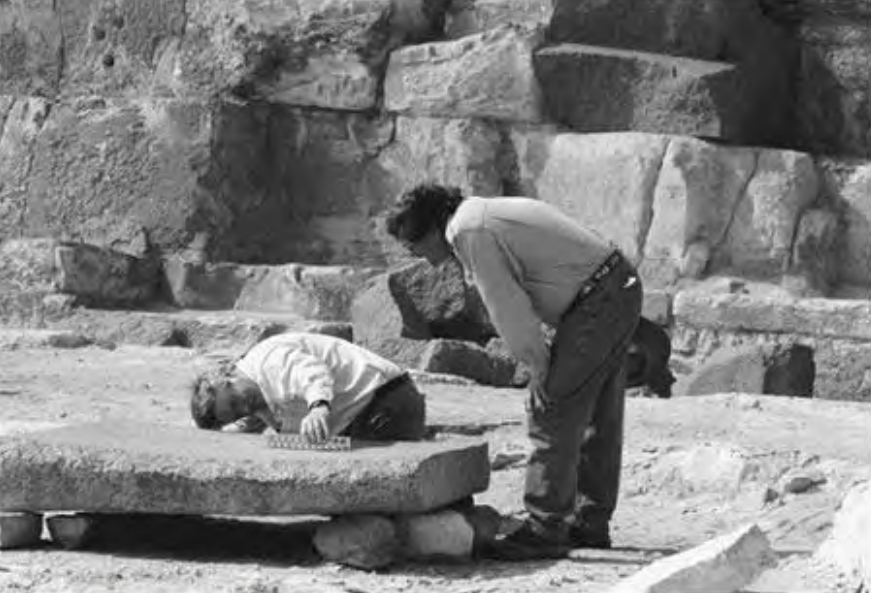

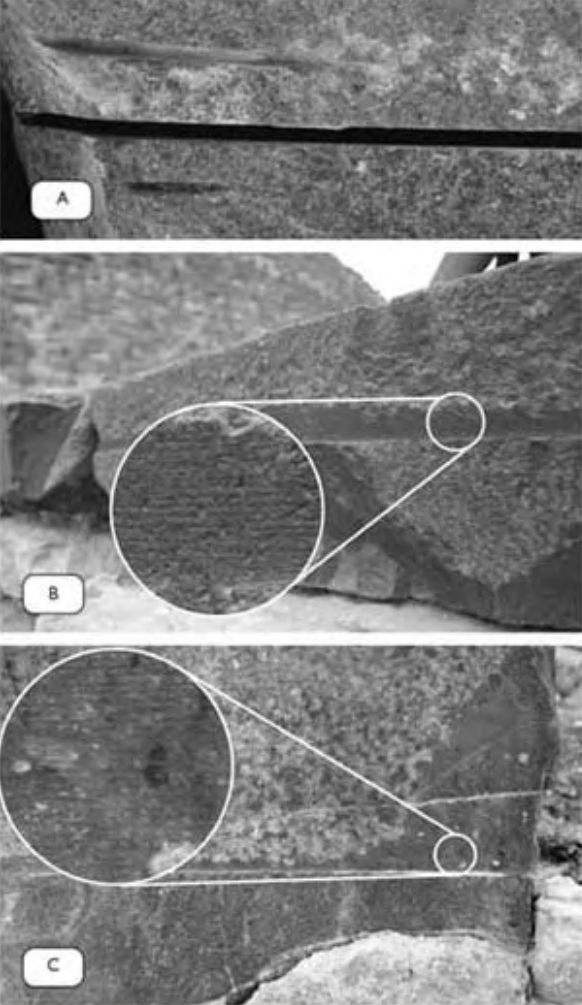

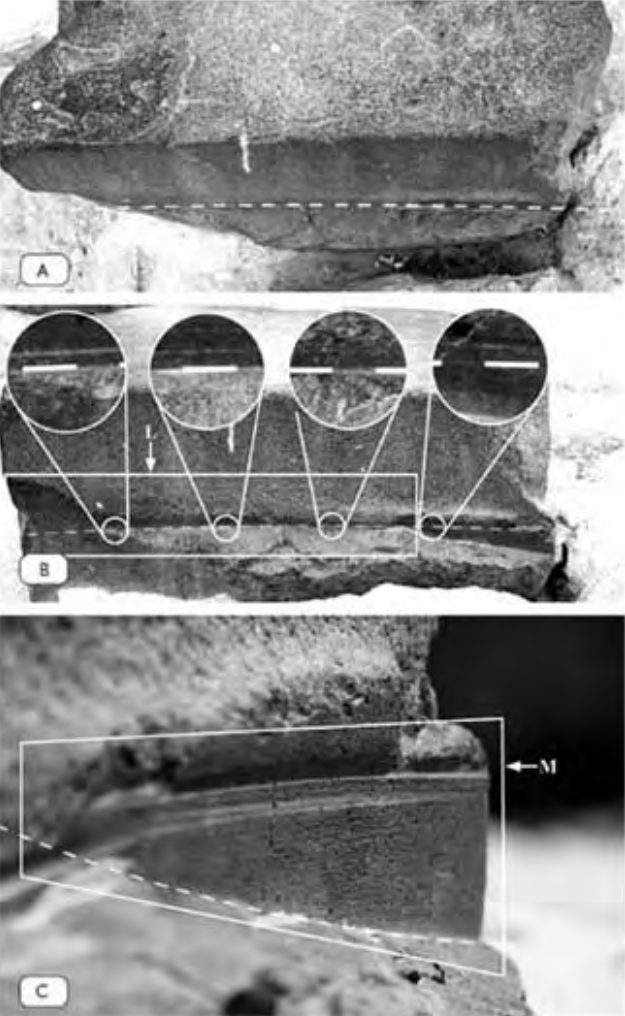

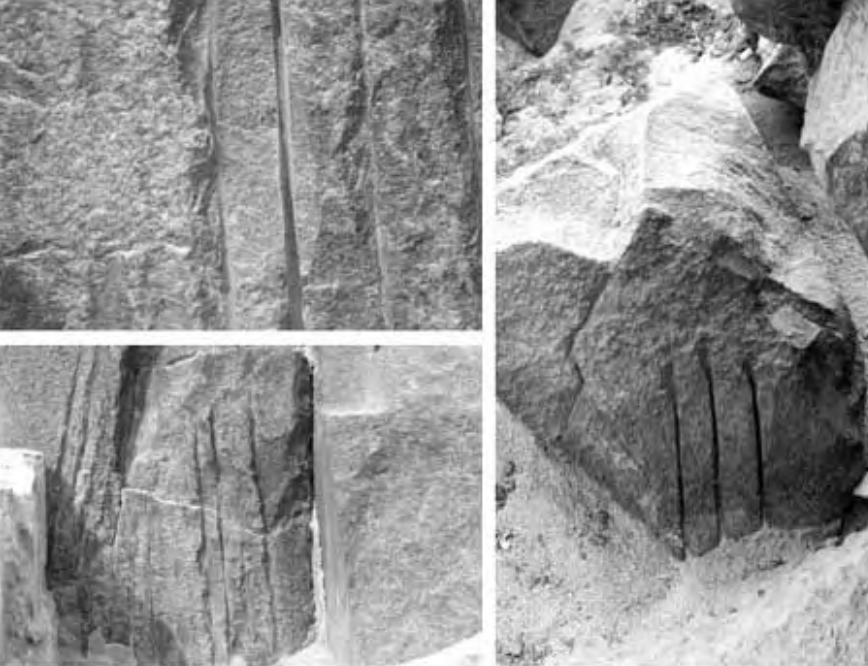

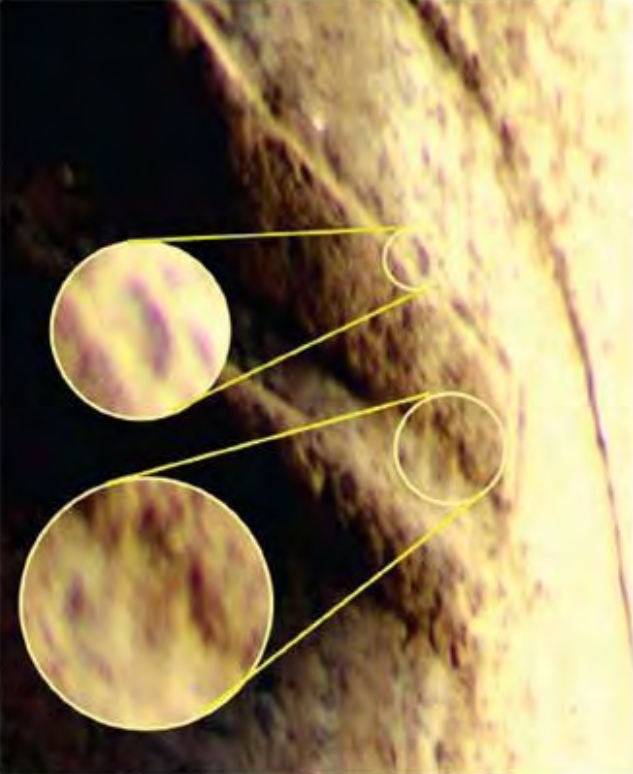

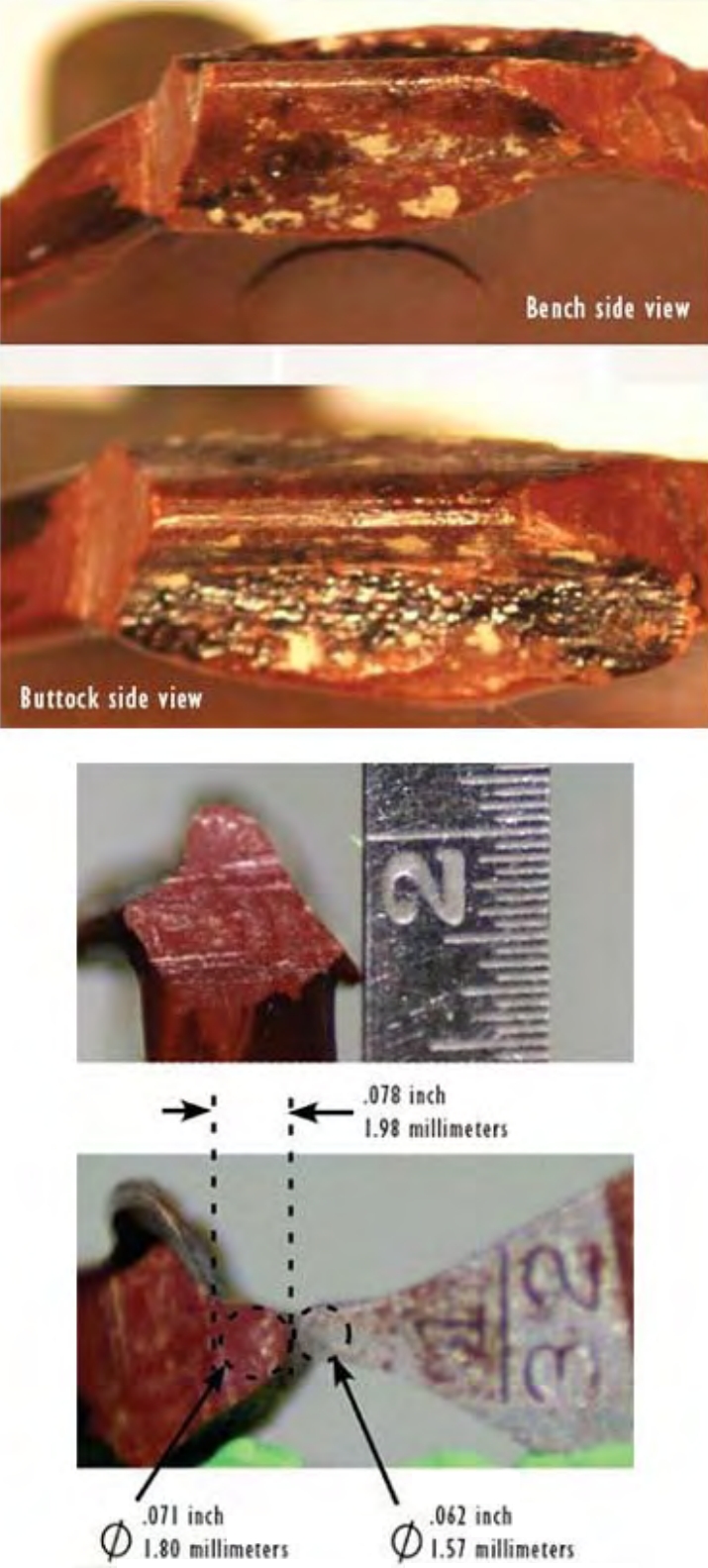

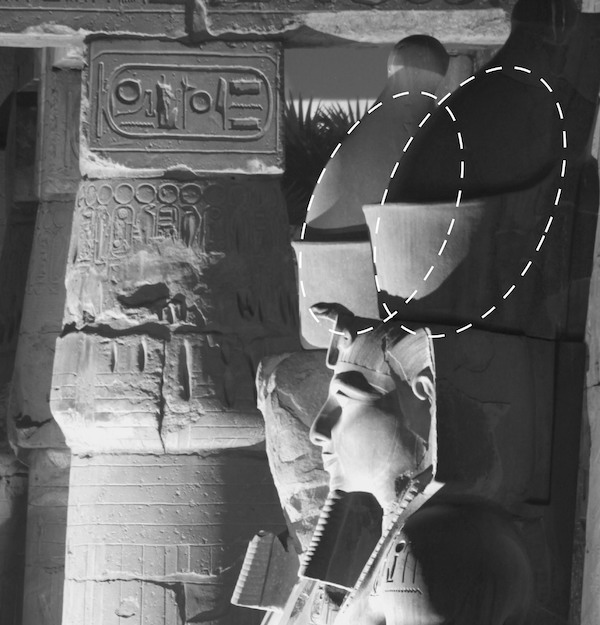

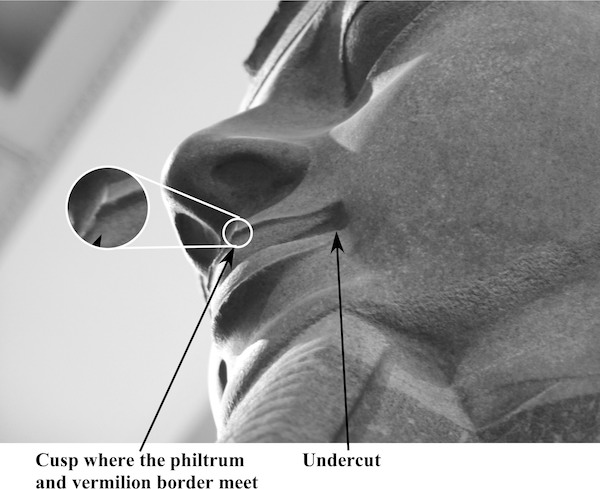

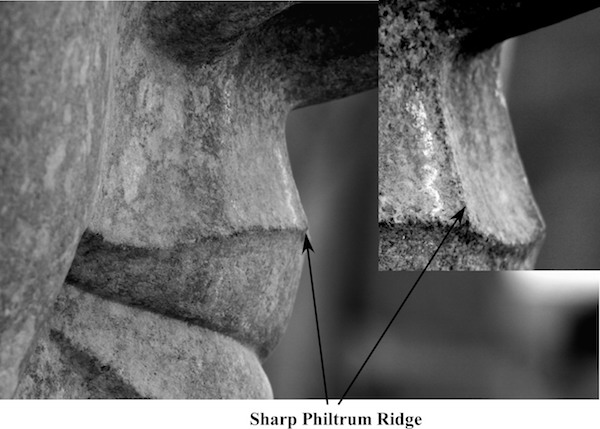

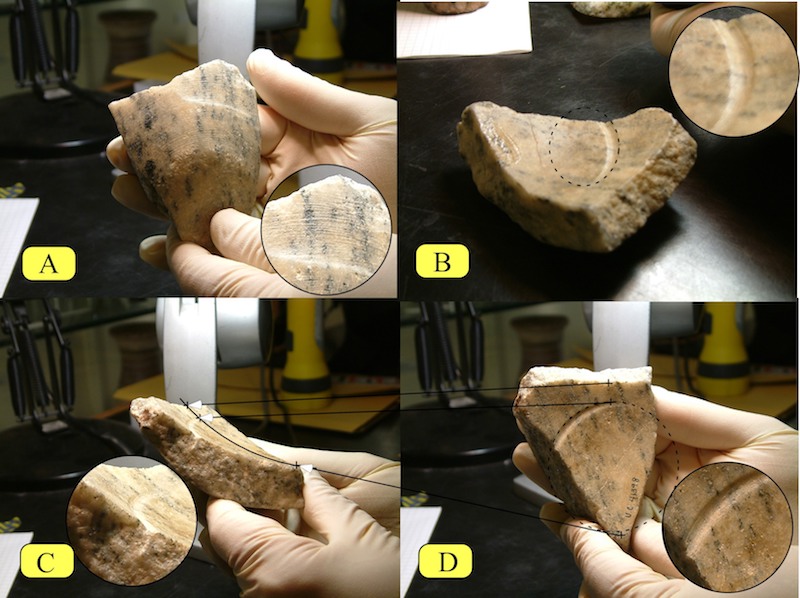

After our visit to the temples in 2006, Dunn studied his photographs and detected in the statues certain features that resembled tool marks — the kind of tool marks that a craftsperson or engineer would recognize. Realizing that he had focused on collecting geometric information and neglected to look for evidence of tool marks, another trip was planned and taken in November of 2008 to further authenticate and more finely focus on what his previous photographs indicated. On this trip I was able, through Dunn’s camera, to see the tool marks on the cheek of one of the Ramses in the Temple at Karnak, even though the head of that statue was some 45 feet in the air. I was later able to examine the resulting photograph, as can the reader later in this book.

I vividly remember my first (and then every subsequent) visit to the Luxor Temple. Although smaller than the nearby Temple at Karnak, the Luxor Temple is impressive. The different areas of the Temple provided an interesting variety of architecture from the hall of the Ramses to the colonnade to the plaza to the inner temple. Each had something different to offer and yet they harmoniously fit together. The imposing Ramses statues hewn out of huge solid blocks of granite, the immense columns, and the fact that the Temple, its contents and its surrounding have existed for thousands of years caused me to wonder about the influence it had on the civilization that built it. From these thoughts, my mind was opened to a new awareness.

As I am confronted with the evidence, both in Dunn’s book and from my own personal observation, I find myself wondering, among other things, how the technology of the ancient Egyptians that allowed them to carve and shape stone as they did was applied in other areas of their society, such as healthcare and dentistry for example. In our socety, advancements in one area of technology are quickly spread to other areas in which those advancements might apply. Wouldn’t the ancient Egyptians have done the same?

While my background as an attorney and a manufacturer qualifies me to evaluate Dunn’s work objectively, I am still awestruck by what he has revealed in his studies and by the disparity between his findings and the understanding I gained in the course of my traditional education on the subject. If, metaphorically speaking, truth lies at the heart of an onion, I have witnessed firsthand as Dunn peeled away layers of that onion to get closer to the heart of technologies employed in ancient Egypt, revealing previously unaddressed questions. While the most obvious and prominent of those questions is how these ancient artifacts were made to exhibit such remarkable geometry and precision, the second most obvious that follows quickly on the heels of the first is why.

At this time, there are no certain answers to these questions, and it is human nature to fill the void of the unanswered question with something. Those who ignore questions because the answers are not apparent are disingenuous. I am reminded of this quotation from John Stuart Mill in Considerations on Representative Government: “From despairing of a cure, there is too often but one step to denying the disease; and from this follows dislike to having a remedy proposed, as if the proposer were creating a mischief instead of offering relief from one.”

A skeptic is defined by Webster's as “a person who questions the validity or authenticity of something purporting to be factual,” while the same dictionary defines cynical as “distrusting or disparaging the motives of others.” In his work, Chris Dunn invites us all to be skeptical of things that we may have never really questioned while, at the same time, he invites rigorous skepticism of his own observations. This skepticism is healthy and helpful. It is not cynicism, however. It is not contempt for the theories or ideas of others or for those who proffer those theories or ideas. It is a questioning and a testing of ones own ideas and theories as well as those of others. In reading and contemplating the pages that follow, I entreat the reader to be skeptical but not cynical.

In exercising skepticism while reading Dunn’s work, also bear in mind this quotation from the Wizard in the play “Wicked”: “Back where I come from we believe all sorts of things that aren’t true … we call it history.”

Perhaps a more famous Winston Churchill quote, “history is written by the victors” should be considered. The history of Egypt traditionally taught in the west has, for the most part, been written by western scholars who followed on the heels of their armies. I am confident that the obvious sophistication of the ancient Egyptians revealed in this book will, in due time, prompt western scholars and others around the world to reexamine what has been written about ancient Egypt and to consider what else the citizens of that ancient civilization, by whatever means, accomplished.

Judd C. Peck, Esq.

Judd C. Peck graduated from the University of Illinois College of Law (magna cum laude) in 1978. In 1989, he took the helm of Danville Metal Stamping in Danville, Illinois, and became its President and Chief Executive Officer.

Those who have come into my life — whether personally, professionally, in the flesh, or at the speed of light as packets of electromagnetic energy coursing through the Internet — are the motivators and teachers to whom I am eternally indebted.

For her unwavering support and encouragement, I thank my wife, Jeanne. Her patience and intelligence, not to mention her enthusiasm for my work, are acknowledged with love and appreciation. Thanks and love also to my sons Peter, Alexander, and Geno, who have stood by me and supported all my research and trips to Egypt. For their loving influence in my life, I thank my mother and father and my siblings: Bernard, Celia, Pauline, and Angela.

My sincere gratitude goes to Judd Peck for his wisdom, advice, and friendship. I will always remember and remain humbled by his mission of mercy when he flew to Egypt to assist me in my recovery and return home when I fell ill and was hospitalized in Cairo in 2007. I also extend my sincere appreciation to Edward F. Malkowski, who provided life-saving assistance on that ill-fated trip. Also, my gratitude goes to Cecilia El Nadi, Bahgat El Nadi, Mohamed El Nadi, Semir Gharib, and Sharzhad Awyan for their kindness and help in Egypt. My brother Bernard, sister Angela, and their families who stood by ready to assist, and the people of Danville, Illinois, and many others around the world who expressed concern and gave an outpouring of support to Jeanne and me during this ordeal. My thanks, also, to the staff of the Dar Al Fouad hospital in 6th of October City and Provena Medical Center in Danville, who provided excellent care to a very difficult patient.

The Board of Directors, management, and employees at Danville Metal Stamping have been incredibly supportive and helpful. The opportunities they have given me as well as the encouragement I’ve received while pursuing this rather offbeat avocation are of inestimable value. For their assistance in several research projects that required machine-tool work, I would like to thank Tom Neal, Don Reed, James Brown, and Doug Carter.

Dr. Arlan Andrews Sr. has helped immensely over the past thirty years with advice and encouragement. I cannot thank him and his wife, Joyce, enough for their incredible support. The irrepressibly passionate Stephen Mehler and Theresa Crater, who sometimes get more excited about my work than I do, have been valuable supporters and have shined their own bright light on the true heritage of the ancient Khemitians (Egyptians). Thanks and blessings to Norma Eckroate for her incredible support and promotion of new information about ancient cultures. For their continued support and feedback I am indebted to Paul and Ardith Keller, Jeff and Judie Summers, David Hatcher Childress, Doug Kenyon, Paul Brenner, Dr. John DeSalvo, Michael Schneider, George Noory, Dr. Dustin Carr, Jennifer Bolm, the late Abd’el Hakim Awyan, Ashraf Williams, Gouda Fayed, Antoine Gigal, Alain Hubrecht, Dr. Hossam Abulfotouh, Carol Radford, Jeff Rense, Bart Haas, Susan Hale, Dan Hamilton, Jaques and Visne Grimault, Susan Alexjander, Dr. Randy Ashton, Dr. Dustin Carr, Steve Garcia, James Hagan, John Heckler, Will Hemphill, Gary Lickfett, Stuart Mitchell, Robert Bauval, Dr. Robert Schoch, Michael Cremo, Dr. J. J. Hurtak, and Colin Wilson.

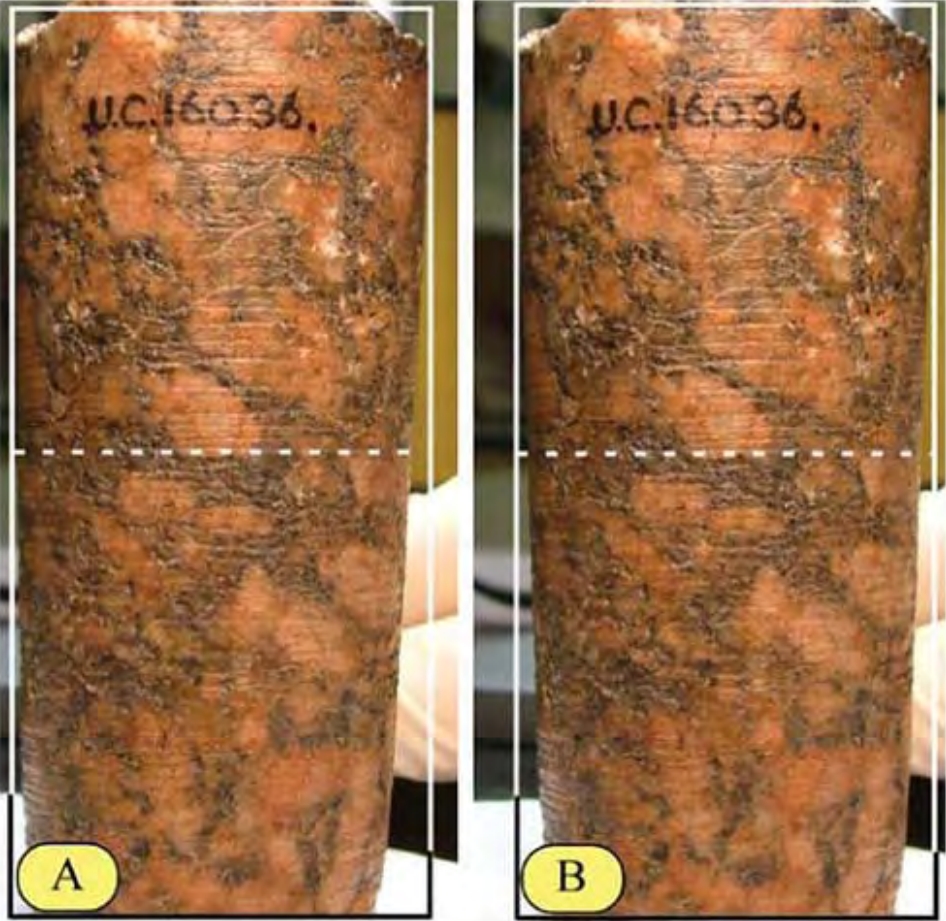

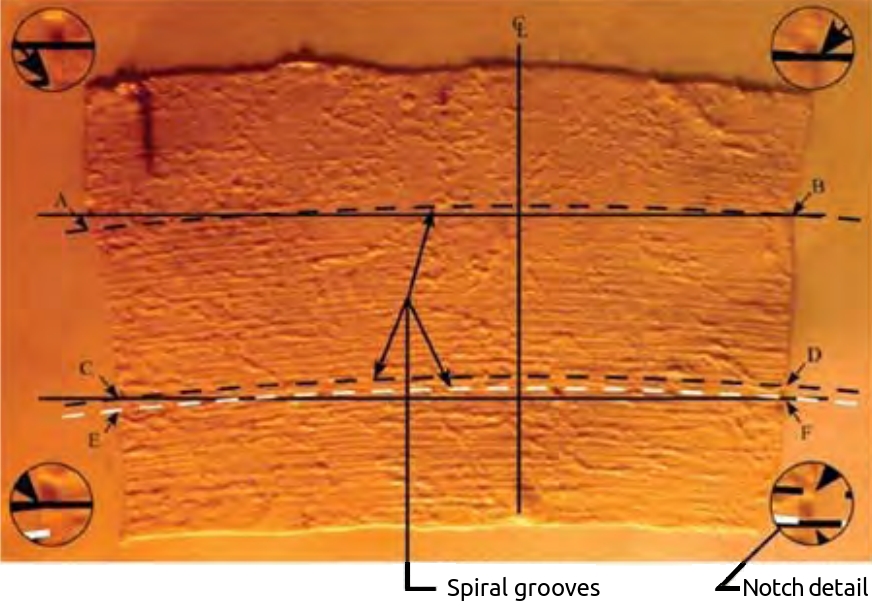

For their contribution to a greater understanding of Petrie’s infamous Core 7, I would like to thank Dr. Stephen Quirke and James Hale of the Petrie Museum; Malcolm McClure and Nick Annies for their assistance in the Petrie Museum; Ian Lawton and Chris Ogilvie-Herald for the impetus provided in their book; Graham Hancock, Santha Faiia, and Nick and Angie Annies for their hospitality while I was in London.

Special thanks go to Dr. Zahi Hawass for his Egyptian hospitality and helpfulness in providing permission to the worker’s village, the Great Pyramid, and the Serapeum. To Adel Hussein Mohamed, the director of Saqqara and lately of Giza, who was a perfect host during the visit to the Serapeum; and to Gail Fallen of Grizzly Adams Productions for making those events possible. Mike Leckie for his talent, expert opinion, and gorgeous photographs; Patrice Pooyard for his vision and passion; John Anthony West, an enormously enjoyable host and companion who I found was always willing to listen to a different point of view; Andrea Mikana for contacting me before visiting the Unfinished Obelisk and asking me if there were any images I needed: the results are outstanding. Denys Stocks, for his professional and thorough answers to my e-mailed questions, and Marcus Allen, for his interest and input regarding the Petrie Core #7.

In preparing this book for publication I am indebted to Greg Brown who offered his help as an editor and a sculptor and who provided expert feedback during the writing of the first draft. From Inner Traditions • Bear & Company, I would like to thank, in the order I met them, Rob Meadows; Cynthia Fowles; Jon Graham; Jeanie Levitan; Kristi Tate; Peri Swan; a marvelous project editor, Chanc VanWinkle Orzell; Manzanita Carpenter; and all others who are a part of this unique publisher’s staff.

Last but not least, I should mention the value brought by hundreds of online forum participants who have provided both positive and negative feedback. I appreciate the comments and the challenges, and I hope they will continue.

Illustrations and photographs are copyright Christopher Dunn, 2006-2010, except for the following copyright holders who have my sincere thanks and appreciation for their critically important contrbutions to this book.

Figure 3.5: thanks to Jessica Brackmann of Champaign, Illinois.

Figures 7.15 and 10.31: Dr. Arlan Andrews Sr. of Padre Island, Texas.

Figures 11.1, 11.3, 11.4, 11.8, 11.12, and plate 26: Nick Annies of Cambridge, UK.

Figures 1.19, 4.3, 6.6, 6.9, 11.6, and 11.7: taken by author and printed with the permission of Danville Metal Stamping Co., Inc.

Plate 19 upper and lower left: Jacques Grimault of Paris, France; 2005 Egypt Project.

Figure 9.3: Bart Haas of Pekin, Illinois.

Figures 5.6, 6.15, 9.10, and plate 19 right: Dan Hamilton of Canada.

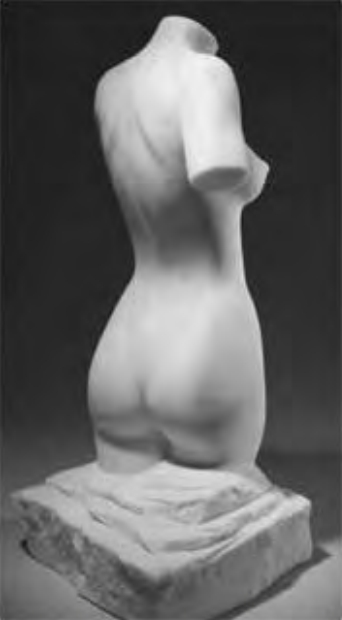

Figures 9.8 and 9.9: Photograph by David Loveall and copyright Mike Leckie of Eugene, Oregon, 2007.

Figures 6.3, 6.4, and 6.5: Glenn McKechnie, reproduced under the guidelines of Creative Commons License Deed, available at https://creativecommons.org.

Figure 6.10 and plate 13: Stephen Mehler of Colorado.

Figures 8.1, 9.11, 9.12, 9.13, and 9.16: Andrea Mikana-Pinkham of Sacred Sites Journeys, Sedona, Arizona.

Plate 11: Joakim Moller of MadCAM Mould and Die CAM Systems, Romakloster, Sweden.

Figures 9.17, 9.20, 9.21, 11.18 upper left, and plate 19 upper and lower left: Patrice Pooyard of Paris, France.

|

Tell me, Mr. Hoover, what are your interests? |

It is possible that Mr. Hoover’s confused lady acquaintance had the wrong impression of what an engineer does, since a train driver is also known as an engineer. There are mechanical engineers, electrical engineers, materials engineers, computer engineers, construction engineers, quality engineers, and safety engineers. And all may not be considered gentlemen — many you may meet will be ladies. Each engineer works in a specialized field, and within those particular disciplines are subgroups that work in myriad industries that form the fabric and backbone of modern civilization. Of themselves and their machines, the life of an engineer is frequently punctuated with Scotty’s Star Trek lament, “Can’t take much more o’ this, Captain!”

Perhaps unbeknownst to you, the engineers’ labors have a direct affect on your daily life. For instance, you have just arrived in the office, hung up your coat, and poured yourself a cup of your favorite morning beverage. An army of engineers and artisans worked to create the technology that has allowed your morning ritual to happen. Crafted into the car, train, or bus and the elevator that carried you to your destination are the labors of the modern artisan. At some location miles away, perhaps on another continent, the skillful eye and hands of artisans guided the tools that created the coffee maker and processed the coffee.

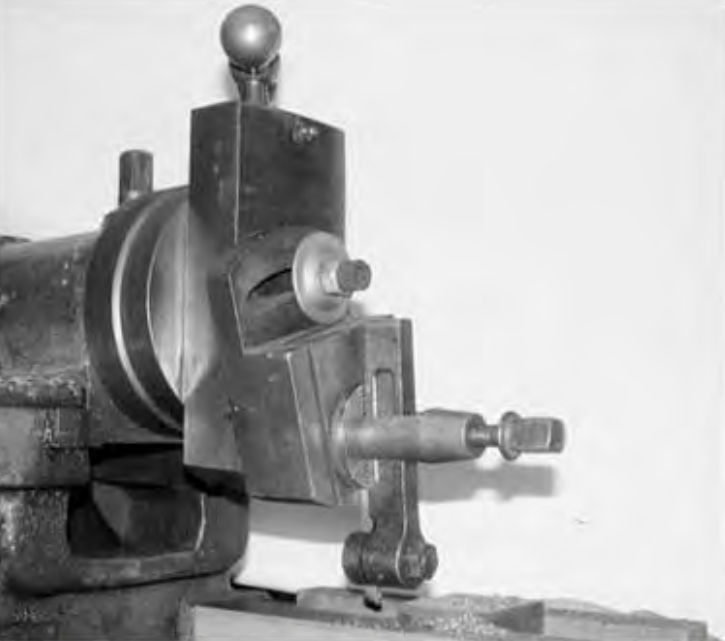

The Industrial Revolution of the 1800s propelled Western civilization forward in terms of labor-saving devices. Around this time, many of the machines that are now used in manufacturing were either invented or improved. Yet the most basic of machines, the lathe, has been around in one form or another for centuries — originally in the form of a potter’s wheel. Its development as an efficient metal-cutting machine grew from the invention of the steam engine, which powered everything from textile mills to Stephenson’s Rocket, the first steam locomotive to convert linear motion to rotary motion and use that rotary motion to propel itself along two rails at the dizzying speed of twenty-five miles per hour.

In the past sixty years, technology has advanced rapidly in directions that many people, except science fiction writers and futurists, could not even have imagined possible. Discoveries and innovations in the field of physics have introduced new patterns of thought in the minds of scientists and inventors. Like legs on a centipede, branches of science, engineering, and manufacturing, along with the creative genius of gifted artists who are now an essential part of the design of functional products, move forward, independently and in unison, each drawing on the other for inspiration and survival.

Three hundred years before the Industrial Revolution was in full swing, geniuses arose among their peers and made their mark, adding to the prosperity and understanding of future generations. The genius of Leonardo da Vinci, Copernicus, and Galileo is well known. During this period, mathematicians, astronomers, and philosophers laid the groundwork for the pursuit of scientific inquiry and changing the worldview of humanity and its place in the universe. With its genesis in the 1500s, what is now known as the Scientific Revolution fought against the church and superstitious beliefs to create the foundation of modern science. The heliocentric theory of Nicolaus Copernicus shattered many beliefs of the earth’s preeminence in the universe, and the Catholic church, which opposed such heresy, fought tooth and nail to stop the rush of intellect that ultimately reshaped our beliefs about nature and ourselves. Rene Descartes, a devout Catholic himself, cut through the confusion that had reigned for so long with a remarkably simple philosophy that to us is a part of life, but in his day was counter to the philosophy of the church, for it would ultimately challenge the church’s own philosophy and teachings. In “Discourse on the Method of Rightly Conducting the Reason and Seeking for Truth in the Sciences,” Descartes sets forth three guidelines that he followed in his own work:

![]()

The first of these was to accept nothing as true which I did not clearly recognize to be so: that is to say, carefully to avoid precipitation and prejudice in judgments, and to accept in them nothing more than what was presented to my mind so clearly and distinctly that I could have no occasion to doubt it.

The second was to divide up each of the difficulties which I examined into as many parts as possible, and as seemed requisite in order that it might be resolved in the best manner possible. The third was to carry on my reflections in due order, commencing with objects that were the most simple and easy to understand, in order to rise little by little, or by degrees, to knowledge of the most complex, assuming an order, even if a fictitious one, among those which do not follow a natural sequence relatively to one another.1

From the birth of the Scientific Revolution to the Industrial Revolution the knowledge of the world has advanced at a rapid pace. Up until today, this advancement has spanned five hundred years. Within that time we have gone from an agrarian society with a much lauded, simple, pastoral existence to a complex industrial society with products that were undreamed of when the creator of the world’s first successful locomotive, Robert Stephenson, cried out, “full steam ahead!”

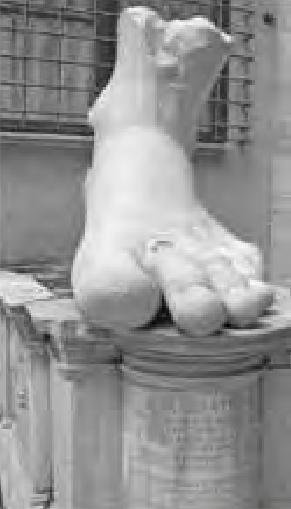

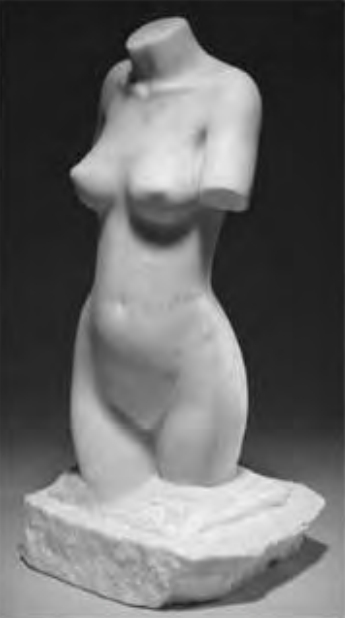

Punctuating each stage of civilization’s development are major building projects that by necessity or demand incorporate the state-of-the-art building construction of their period. The landscape of the ancient world is dotted with fabulous structures that are breathtaking in their complexity. The Egyptians and Mayans had their pyramids and temples. The Hindus crafted elaborate temples throughout Asia. The Greeks built the Parthenon, and the Babylonians constructed the Jupiter Temple and the fabled Hanging Gardens. The Romans made their mark all over their world, with engineering geniuses guiding the construction of their famous roads, the Coliseum, and numerous temples and viaducts, while Roman sculptors guided their chisels over marble and alabaster, giving it physical presence and beauty.

With the exception of artifacts such as the mysterious Antikythera Mechanism, an astronomical computer found by fishermen on the sea floor near the island of Antikythera in 1901, the development of technology in the ancient world seems to have clear origins and is fairly well understood.

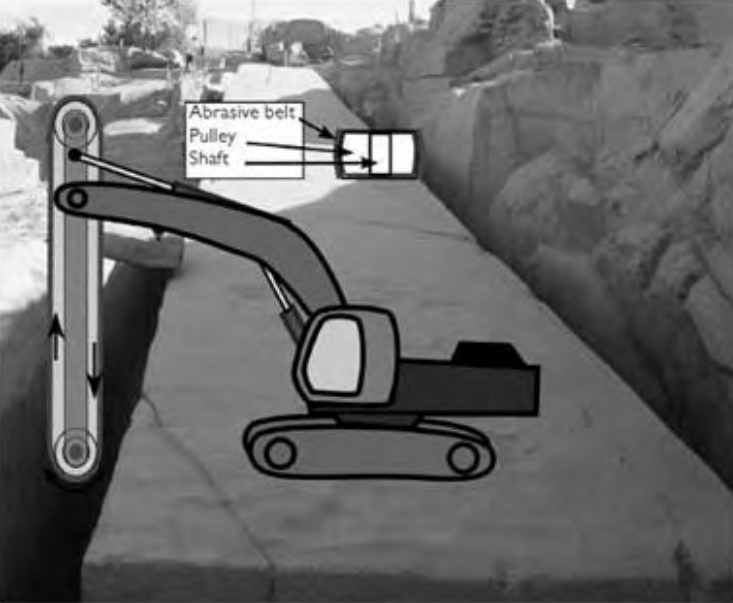

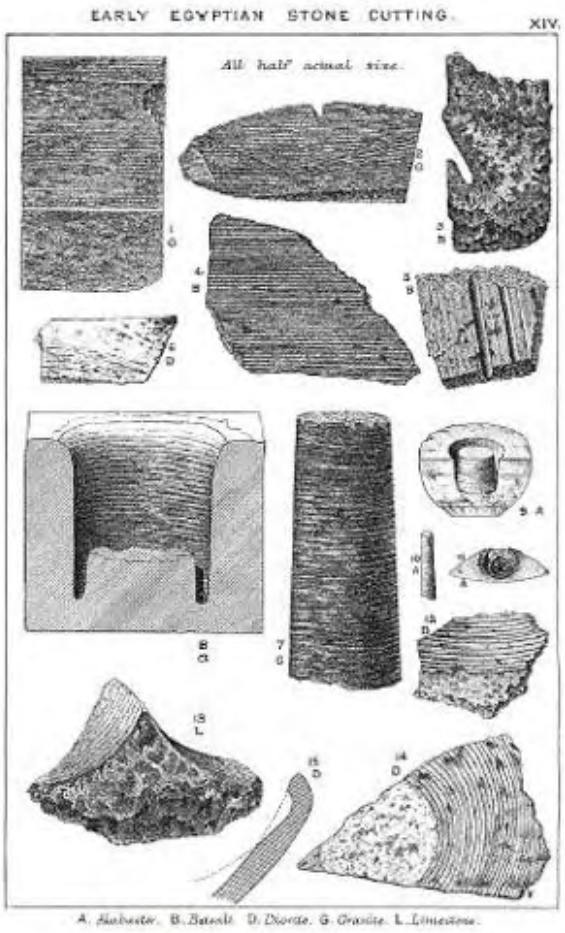

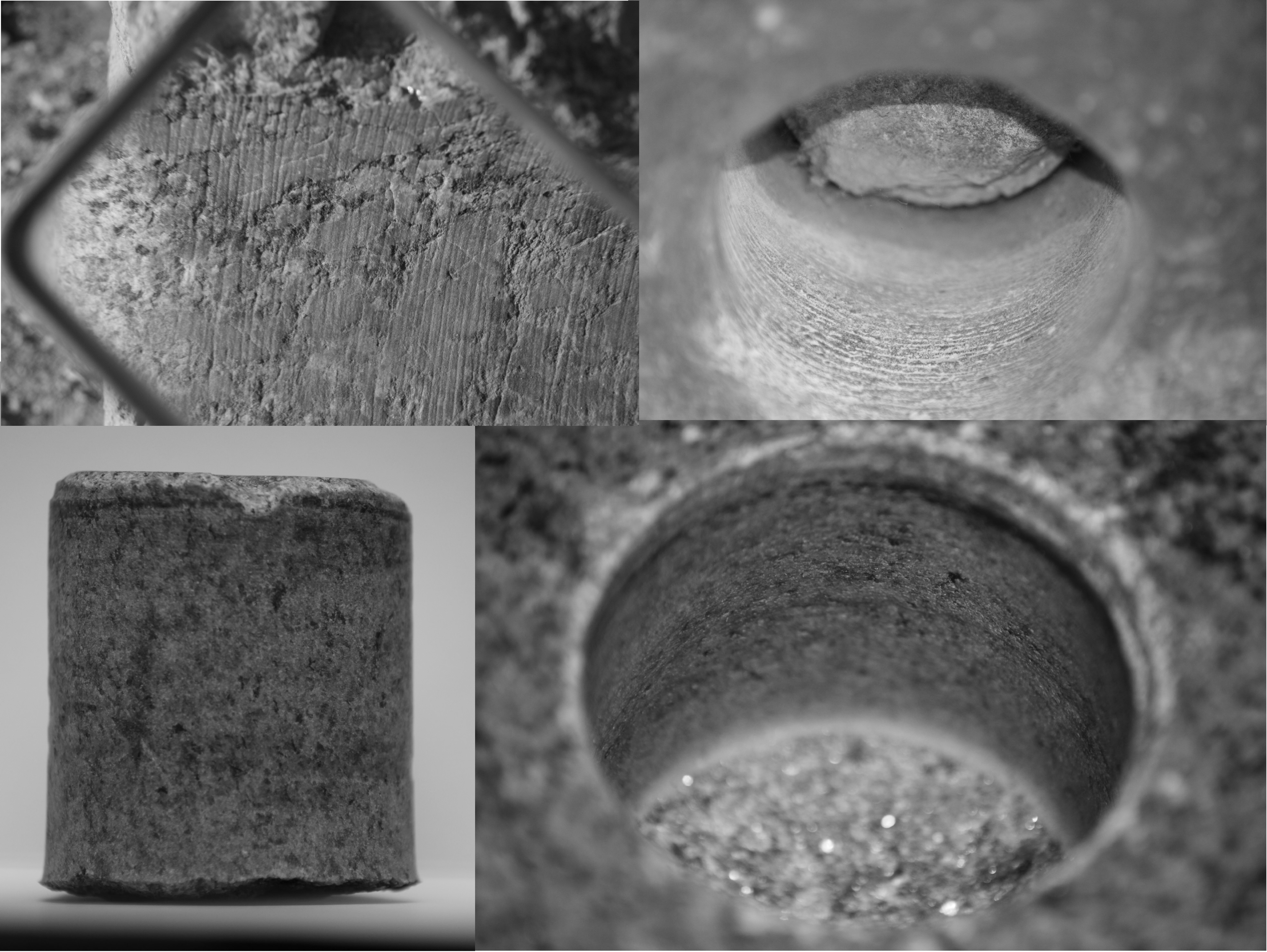

Going back yet further in time, another deep mystery lies in the question of how the ancient Egyptian civilization could have lasted for three thousand years without improving the tools used to quarry and shape stone to near perfection. Since 1984, when Analog magazine published my article “Advanced Machining in Ancient Egypt?” controversy on this subject has persisted. The article proposed that the ancient Egyptians were more advanced than previously believed and that they used advanced tools and methods to cut granite, diorite, and other difficult-to-work stone. It does not seem credible that brilliant architects and engineers would continue to use stone tools and copper chisels for three millennia.

Following this article, I have received input from many kind people from different walks of life. Though much of the feedback I have received has been extremely positive and supportive of the idea that ancient cultures were more advanced than classical archaeology has supposed, there has been some criticism from those who believe that I went too far with my conclusions because I made the mistake of imposing a modern engineer’s viewpoint on an ancient civilization, thereby ignoring its cultural origins, and disrespected the Egyptians’ heritage.

In fact quite the opposite is true. Anyone who suggests that the ancient Egyptians were more advanced actually shows more, not less, deference and respect to their civilization. Such a statement does not diminish their culture in any way. Rather, such a suggestion would elevate the Egyptians’ status in the world. The cultural assumptions that are disturbed most by the idea of an advanced Egyptian race in prehistory lie in the libraries and halls of Western countries and the belief system that has been generated by generations of Western scholars — beginning with Herodotus. It is our own culture’s chauvinistic view of Egypt that threads throughout our history books.

Studies made by archaeologists, historians, and Egyptologists over the past five hundred years have essentially provided us with the modern, conventional view of ancient Egypt. This is an area of intense interest to engineers — such as myself — who find in Egypt a language with which we are familiar. This is the language of science, engineering, and manufacturing. Our counterparts in that ancient land left future generations of scientists, engineers, architects, and those who take their instructions and shape materials to their specifications, with a difficult challenge. This challenge is to recognize what they created and provide evidence-based, reasonable answers that give the ancient engineers credit for what they achieved. With their works, ancient engineers, perhaps unwittingly, created a sort of Mecca for modern engineers and technologists. The engineers and technologists that have taken this “pilgrimage” have discussed many theories, but always at the end we come up short of confidence that the theories are actual truth.

The ancient Egyptians who built the pyramids and temples, who crafted monumental statues out of igneous rock, were thinking with the minds of architects, engineers, and craftspeople. Were ancient archaeologists responsible for the legacy they left us? Without the advice of modern Egyptian architects, engineers, and craftspeople, are today’s Egyptian archaeologists missing something? Are modern interpretations of the awesome feats of the ancient Egyptians irrelevant in providing new and powerful information about this ancient culture? Are the thoughts and conclusions of Western writers and travelers who stood in front of the Great Pyramid one hundred years ago (or some forty-five hundred years after it was built) more intrinsically linked to the ancient Egyptian mind than those who come after them, a century or more later? What can be described as a “modern perspective?” In his time, Herodotus would surely have been considered modern. So were Egyptophiles Petrie, Marriette, Champollion, and Howard Carter — each in possession of a modern mind that was clothed in a fabric of prejudices and stereotypes that existed within their own culture.

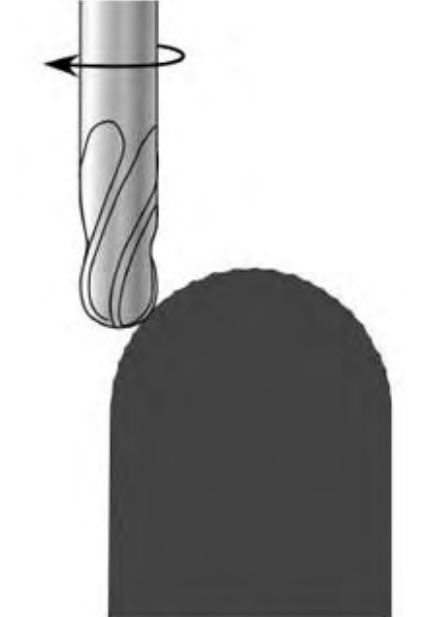

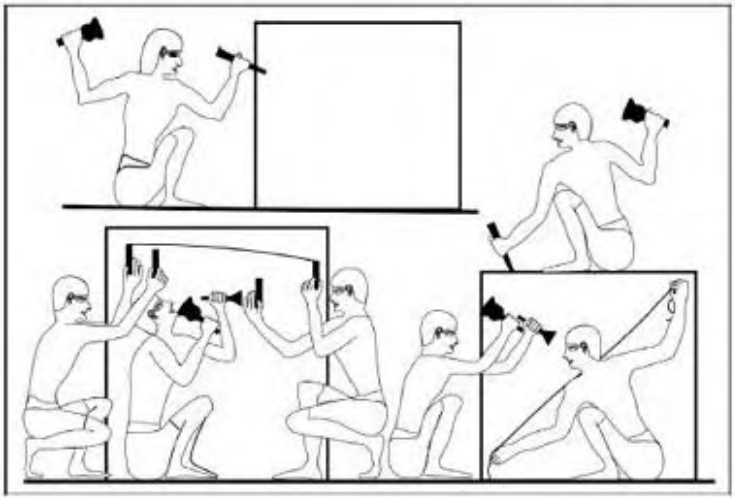

When it comes to completely understanding the ancient Egyptians’ level of technological prowess, there can be no final conclusion. What is left to study today is a mere skeleton of what existed at the time of the ancient Egyptians. This skeleton survives as highly sophisticated and precisely crafted sedimentary and igneous rock. It is my belief that the clothes we have placed on this skeleton are mere rags compared to what should be there. I have proposed in the past that higher levels of technology were used by the ancient Egyptians, but you will find in this book that I have rejected some ideas and cast doubt on all my previous assertions as to the level of technology they enjoyed. At the same time, I cast doubt on the methods of manufacture that Egyptologists have asserted were used to build the pyramids and the glorious temples in Egypt. These methods are primitive and include stone and wooden mallets; copper chisels; tube drills and saws; and stone hammers for quarrying, dressing, and sculpting hard igneous rock. Nobody can claim that they know what was in the minds of the ancient Egyptians. All we have are their works: “By their works, ye shall know them.”*

This book is about the Egyptians’ works, but before understanding the manufacturing and building methods, it is necessary to understand the full scope of each work — exactly what it is we are studying. In the following pages I present another view of ancient Egyptian artifacts: the view of a modern craftsman and engineer made possible through the use and knowledge of modern technology.

After I describe each work, we will examine the methods of construction that have been proposed by Egyptologists and discuss some of the arguments against and for considering other methods that are more advanced. It is my sincere wish that the artifacts are respected and understood for what they are. They are priceless treasures and would have astronomical value if produced today using modern tools. Because they are encoded with the knowledge of life on this planet in prehistory and hold a powerful message for future generations, their worth in monetary terms is unfathomable. Their value in raising awareness and dispelling cultural bias, even while short of real answers, cannot be calculated in monetary terms.

1 René Descartes, “Discourse on the Method of Rightly Conducting the Reason and Seeking for Truth in the Sciences,” Great Books of the Western World, vol 31 (Chicago: William Benton, 1952), 47.

* Matthew 7: 20.

Bear & Company

One Park Street

Rochester, Vermont 05767

Bear & Company is a division of Inner Traditions International

Copyright © 2010 by Christopher Dunn

All rights reserved. No part of this book may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without permission in writing from the publisher.

Library of Congress Cataloging-in-Publication Data

Dunn, Christopher, 1946-

Lost technologies of ancient Egypt advanced engineering in the temples of the pharaohs / Christopher Dunn.

p.cm.

Includes bibliographical references.

Summary: “A unique study of the engineering and tools used to create Egyptian monuments” - Provided by publisher.

ISBN: 978-1-59143-102-2 (pbk.)

eISBN-13: 978-1-59143-968-4

1. Egypt-Civilization-To 332 B.C. 2. Engineering-Egypt-History-To 1500. 3. Technology-Egypt-History-To 1500. 4. Pyramids-Egypt-Design and construction. 5. Temples-Egypt-Design and construction. 6. Monuments-Egypt-Design and construction. I. Title. DT61.D86201O

932-dc22

To send correspondence to the author of this book, mail a first-class letter to the author c/o Inner Traditions · Bear & Company, One Park Street, Rochester, VT 05767, and we will forward the communication or contact the author at www.gizapower.com.

About Inner Traditions · Bear & Company

Founded in 1975, Inner Traditions is a leading publisher of books on indigenous cultures, perennial philosophy, visionary art, spiritual traditions of the East and West, sexuality, holistic health and healing, self-development, as well as recordings of ethnic music and accompaniments for meditation.

In July 2000, Bear & Company joined with Inner Traditions and moved from Santa Fe, New Mexico, where it was founded in 1980, to Rochester, Vermont. Together Inner Traditions · Bear & Company have eleven imprints: Inner Traditions, Bear & Company, Healing Arts Press, Destiny Books, Park Street Press, Bindu Books, Bear Cub Books, Destiny Recordings, Destiny Audio Editions, Inner Traditions en Espãnol, and Inner Traditions India.

For more information or to browse through our more than one thousand titles in print, visit

www.InnerTraditions.com.

Electronic edition produced by

ePubNow!

|

Editor's note

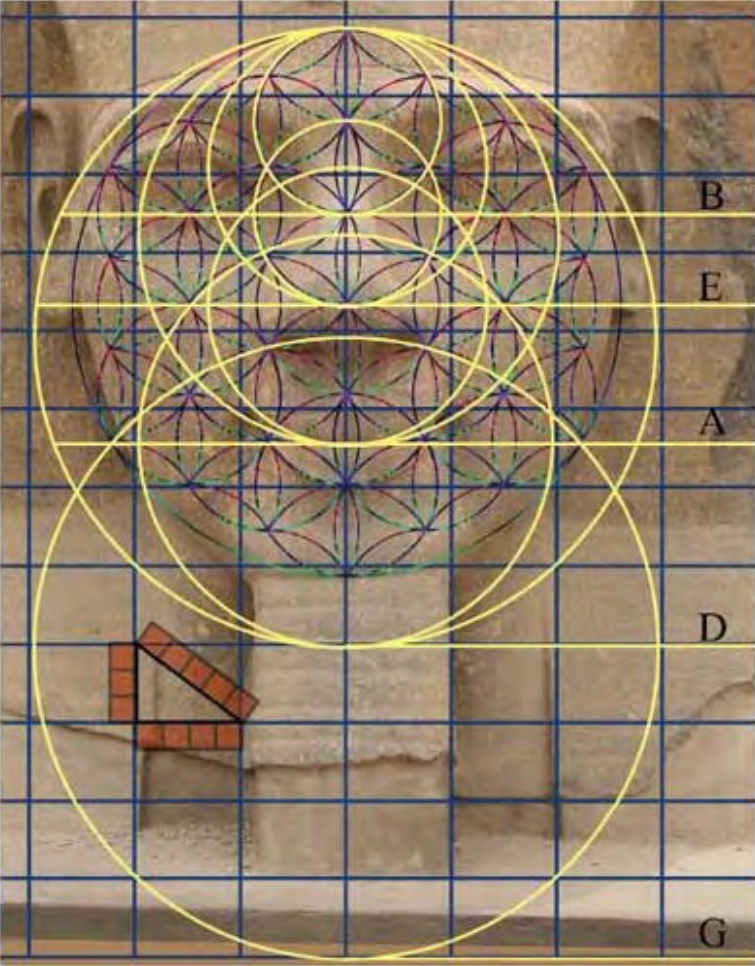

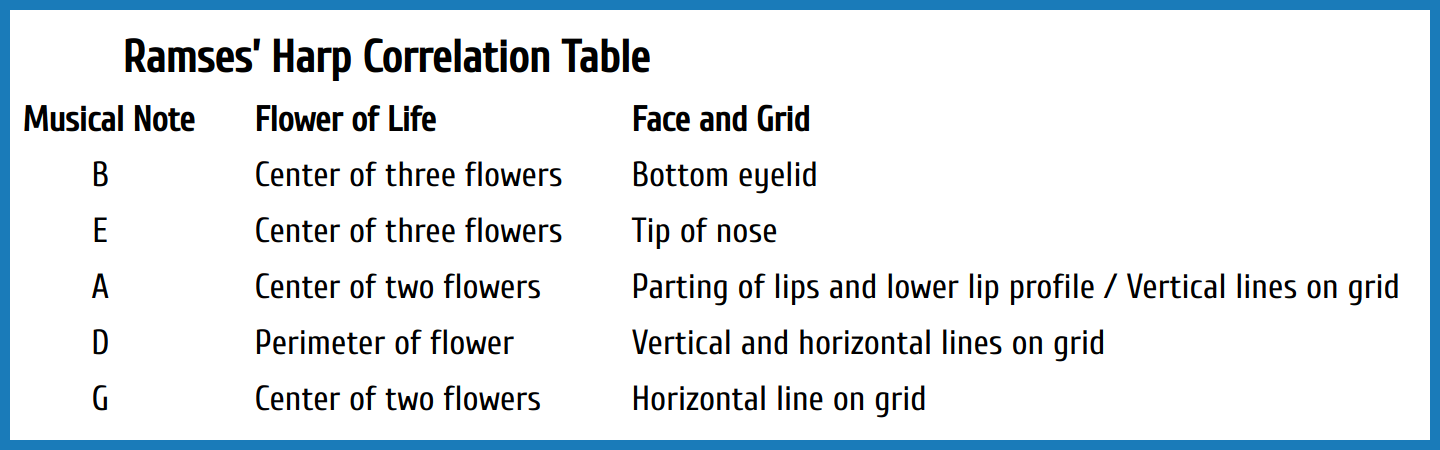

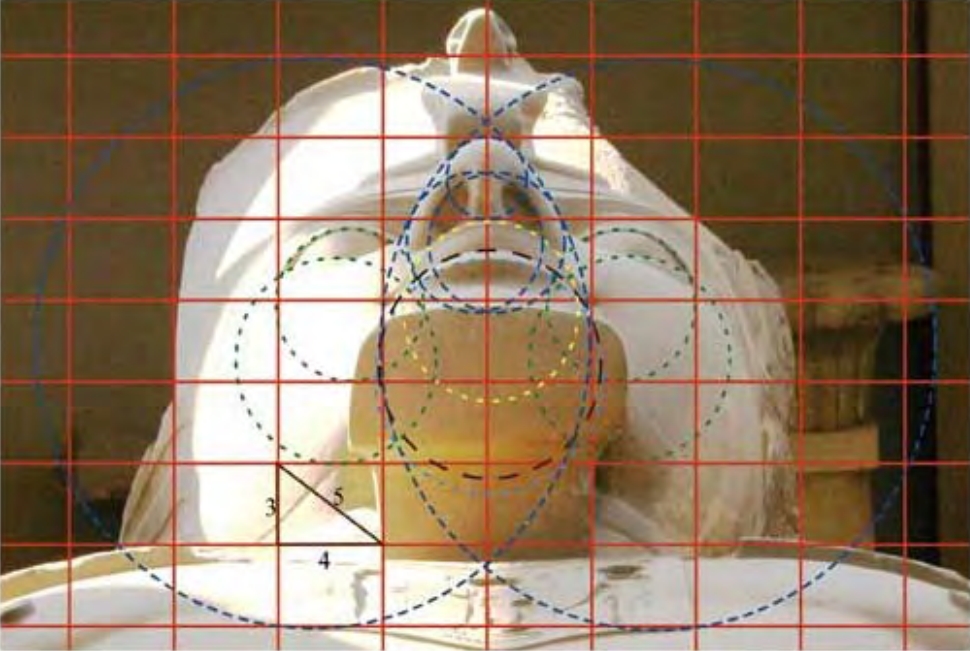

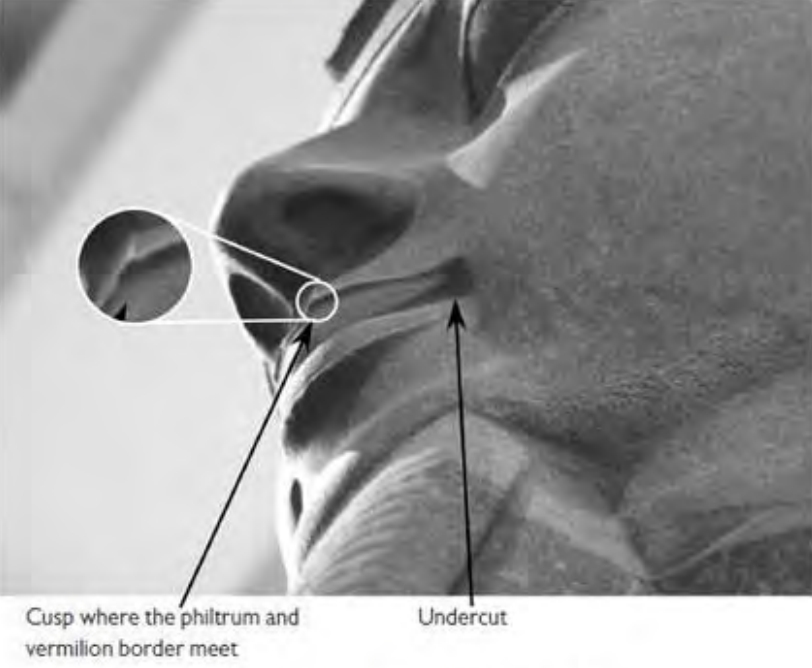

Additional photographs of Ramses Statues found under the last tab (Ramses Statues) of this chapter are from Chris Dunn’s website. |

|

The life of man is a self-evolving circle, which, from a ring imperceptibly small, rushes on all sides outwards to new and larger circles, and that without end. – RALPH WALDO EMERSON, ESSAY ON CIRCLES |

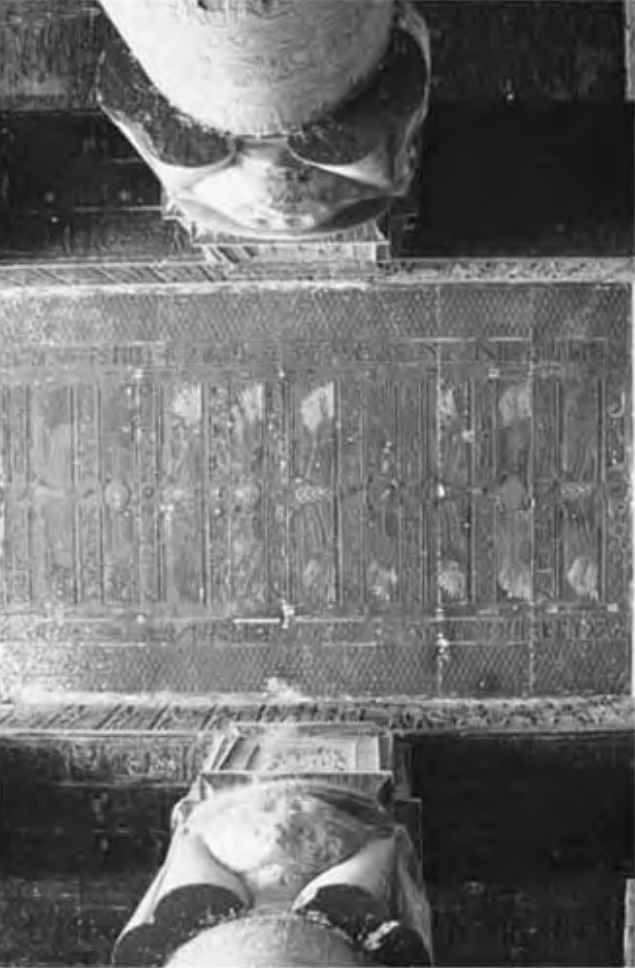

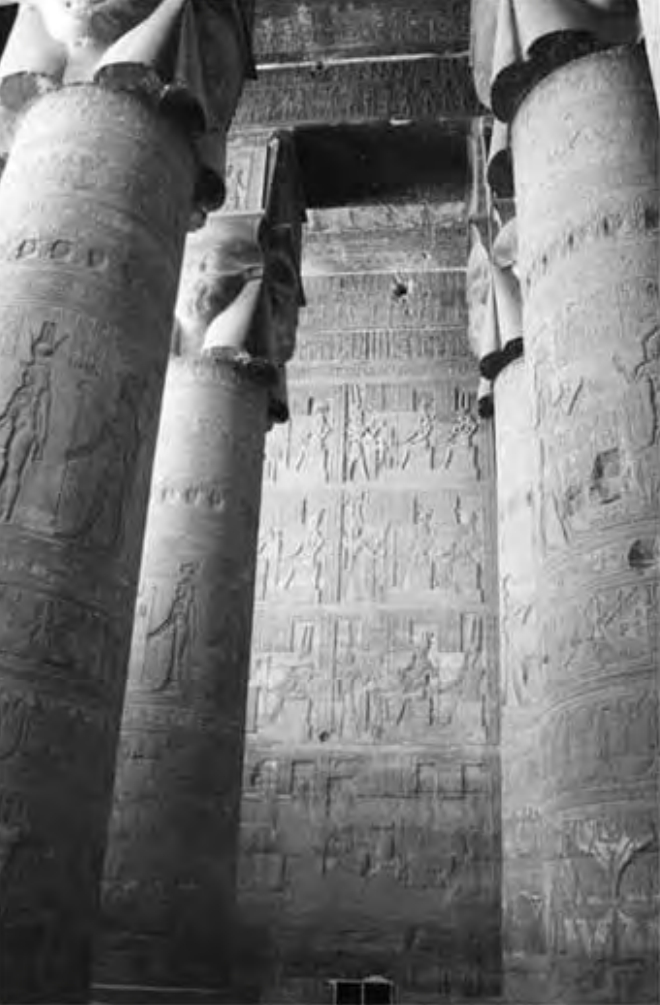

Figure 1.1. The Ramses Hall at Luxor

Figure 1.2. Bust of Ramses outside the Temple of Luxor

|

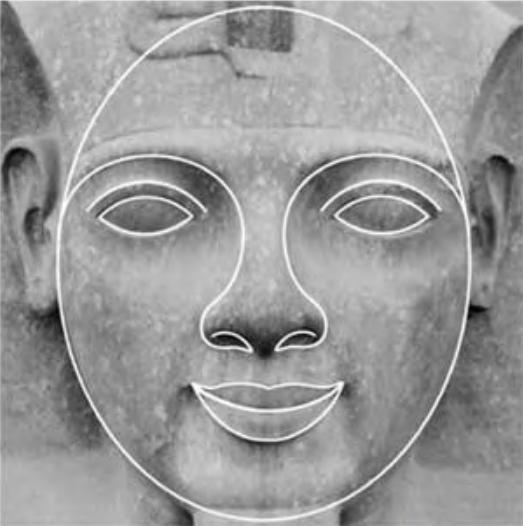

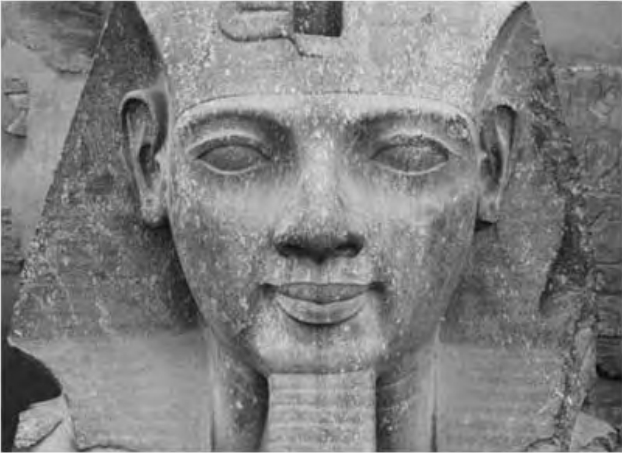

Within the Ramses Hall at Luxor, subtle curves and shaded hues of geometric perfection create an effect that seems designed to mask the real truth about the artifacts. Waiting for millennia for questions that have not been asked, let alone answered, the perfectly crafted granite statues of Ramses II smile and gaze upon each person who enters the hall and tries to come to terms with and grasp the true meaning of the Temple of Amun-Mut-Khonsu at Luxor.

Sometimes referred to as the world's greatest open air museum, the city of Luxor is situated in Upper Egypt, where once stood the ancient city of Thebes, approximately four hundred miles south of Cairo. The temple complexes of Karnak and Amun-Mut-Khonsu stand within the city, and the latter is commonly referred to as the Luxor Temple. Overlooking the Nile River nearby is the Winter Palace where Howard Carter and Lord Canarvon refreshed themselves in the quiet, cool bar. Graceful lateen sails fill and push feluccas on the river, as clouds, haloed by a crimson sun setting in the west, snake like serpents in the evening sky. Monuments, temples, and tombs of the west bank necropolis lie beyond the sails and include the Valley of the Kings, the Valley of the Queens, the Ramesseum, and roads leading to the temples of the north.

If special recognition was given to the billionth visitor to Luxor, I probably missed it by centuries. Millions of tourists go there every year and, in season, jam to capacity the hotels and luxurious floating mansions that cruise the Nile River. Out-of-season accommodations play host to more visitors than a hotel in a normal town would at the height of any tourist season.

In any society, there are geniuses that innovate and make their mark by providing novel and revolutionary iconic images. Within the confines of three dimensions, the subtleties of individual expression allow philosophy, symbolism, and individuality to flow forth into stone, onto canvas, or through the orchestra. This expression guides the chisel and the pen.

Nowhere in the ancient world is the marriage of art and engineering better expressed than at Luxor in Egypt. The temples have inspired many to write eloquently about the city's magnificent monuments, its history, and the archaeological studies that have yielded untold riches in antiquities. The incredibly significant aspect of the artistic attributes of the numerous statues of Ramses is that it stimulates both the right and the left brain to study how their imposing beauty is not only a symbol of an incredibly gifted ancient culture, but also a symbol of manufacturing engineering that would be considered quite relevant in our modern world.

The ultimate function of art in human evolution is a mystery, but there is no mystery about what art does: it communicates, it evokes, it alters the observer. From the profound power of the Lascaux cave images to the spattering of Jackson Pollock, art calls to something within the observer. In the case of Luxor and the images of Ramses, the art is highly stylized, symbolic, and uniform. Even to today's observer, it carries a deliberate message of divinity and eternity, of awe and majesty – which must have been so much more powerful to the ancient Egyptians. On another level, to the sculptor who has worked in stone and to the technologist whose job it is to shape adamantine materials, it calls out a question and issues a challenge: "What am I? How did I come to exist? Build another just like me."

It challenges: "Don't just gape in awe and wonder, shake your head, and walk away. Bring me back to life! Know me – who I was and what I was. The only way to do this is to understand what I am and build another! Why am I smiling? Don't think for a minute that I am content sitting here on my pedestal, misunderstood by the droves that have passed by for centuries. There is more here than meets the eye."

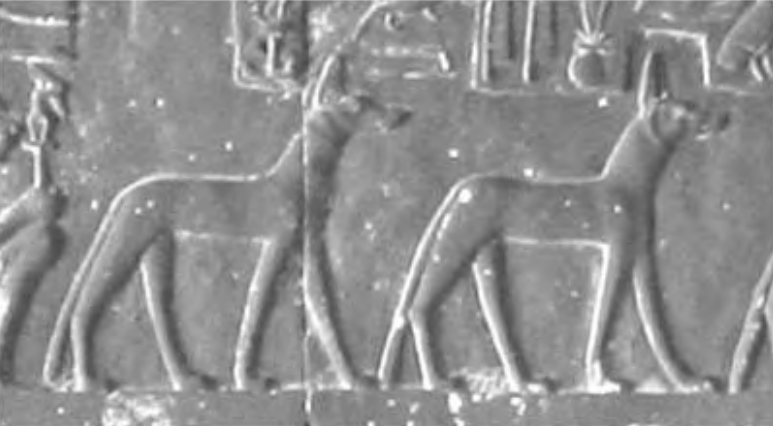

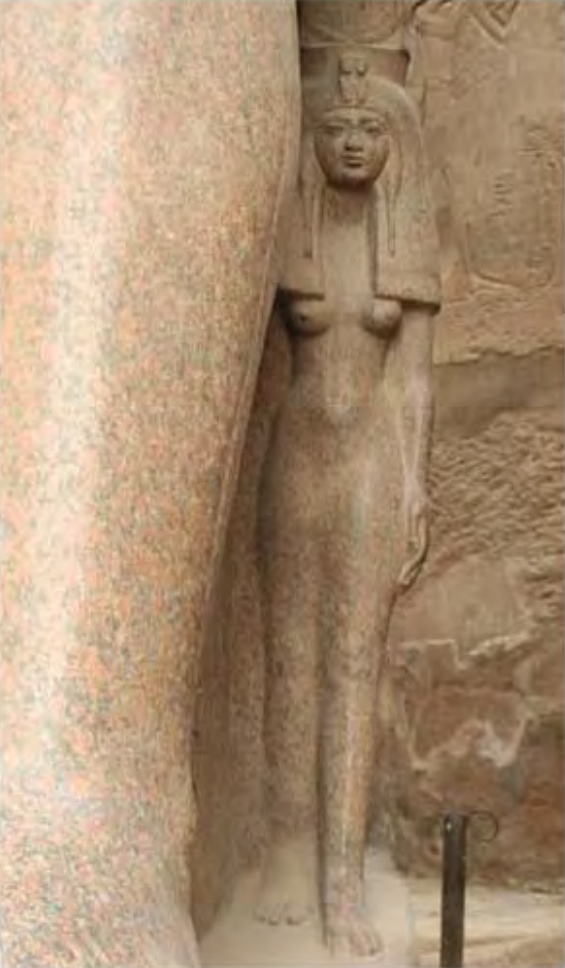

The Ramses challenge was issued in ancient Egypt again and again, from Memphis and Cairo to Luxor and Abu Simbel. Exact replicas of Ramses' image were crafted in limestone, sandstone, quartzite, granite, and diorite. Some pieces, such as the Colossi of Memnon, weigh more than 1,000 tons. Other statues at Luxor weigh 600 tons. In fact, just the crowns that top the statues each weigh more than a ton. The statues are massive — a significant challenge to move and, because they are intricately carved, an even more significant challenge to sculpt. What distinguishes the Ramses statues is the iconic imagery of the perfect face. It seems that no matter which of the Ramses statues we look at, the same smiling face gazes through you, into infinity.

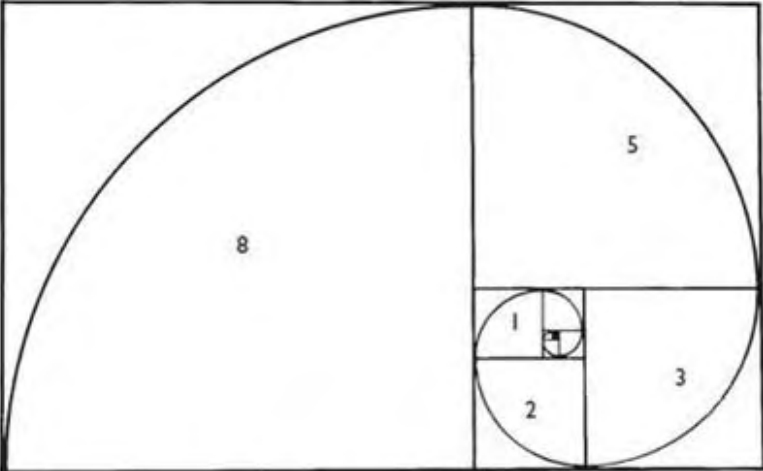

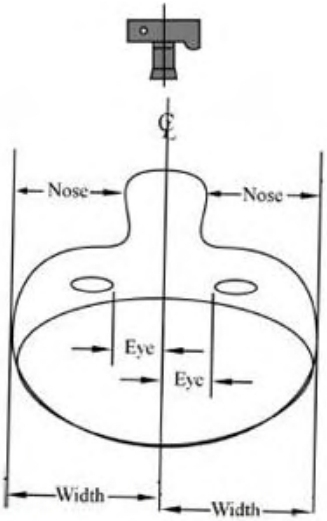

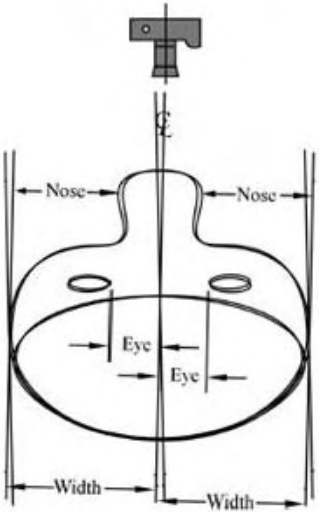

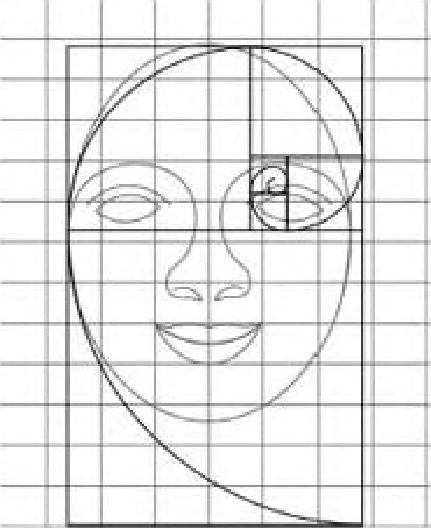

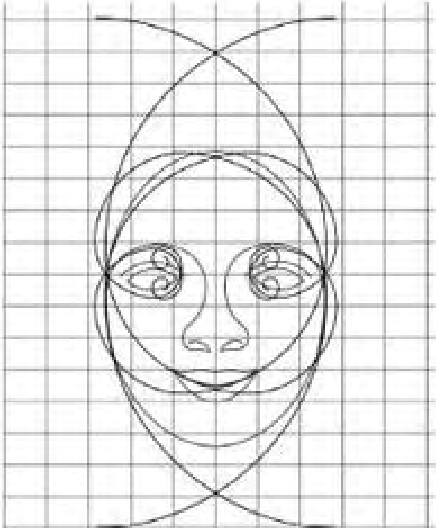

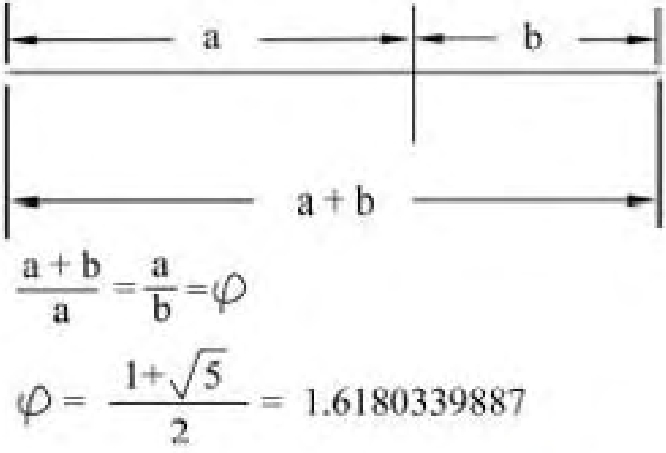

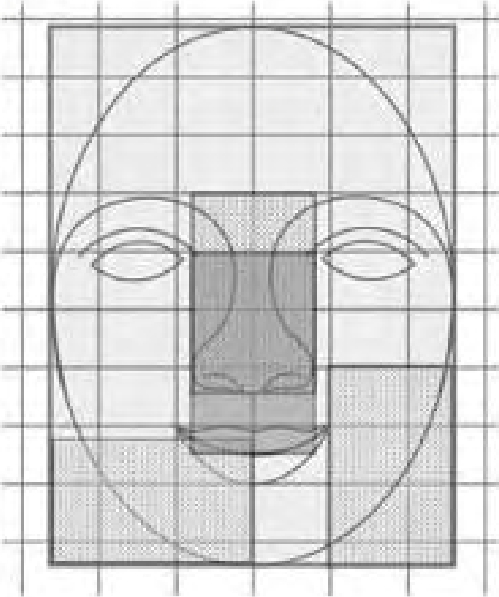

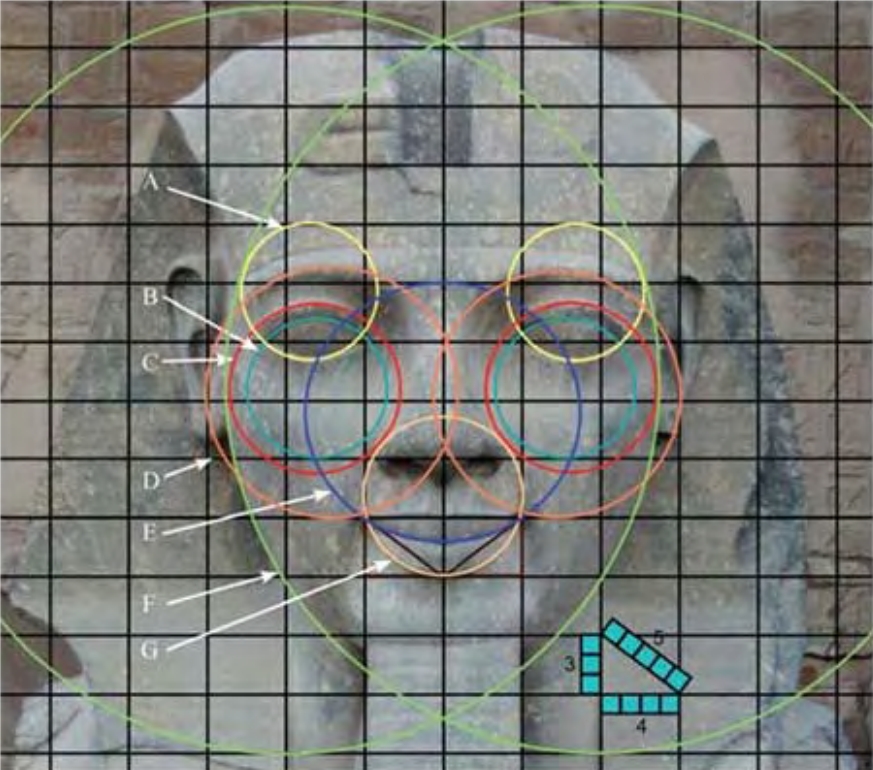

In order to accomplish this effect, the ancient sculptors worked to a uniform system of measurement and a design scheme. Just as today we replicate designs using uniform measures and consistent methods of manufacturing, in ancient Egypt there was a system of design, measurement, and manufacture used to create the Ramses statues. We can then ask the question: What was the fundamental scheme that the ancient Egyptians used to create and re-create this iconic image in stone?

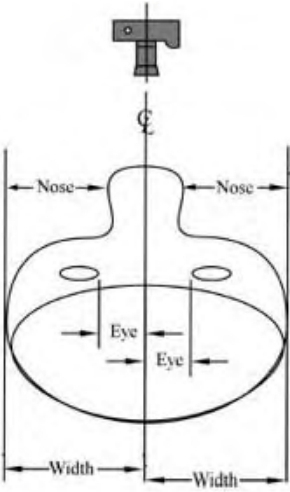

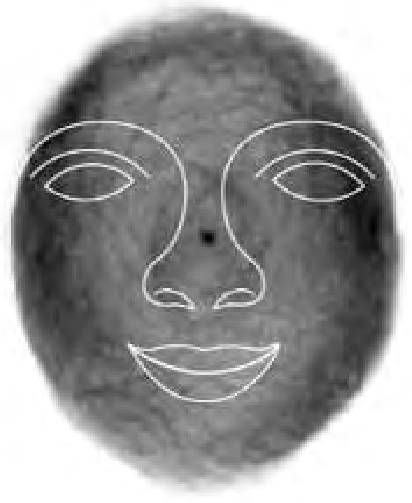

In 1986, I visited Memphis, near Saqqara, and gazed down at the statue of Ramses in the open-air museum. Looking down the length of the statue, it struck me as peculiar that the left and right nostrils were identical mirror images of each other. It is common knowledge that no adult walking the earth has nostrils that are identically shaped. I thought it was noteworthy, but did not follow up and research it further as my focus at the time was on engineering, not art. I was there to study the pyramids and had not planned to visit any temples during my visit. I didn't realize at the time, though, how important my observation would become to my future research.

My interest in the Ramses statues was rekindled when I visited Luxor in November 2004. Though I had been to Egypt four times before and learned to love the Egyptian people for their hospitality and sense of humor, this was my first visit to the temples in Upper Egypt. Words cannot describe my feelings of wonder and awe as I absorbed the temples not only from a philosophical and spiritual aspect but also with my engineer's brain. These temples impressed upon me indelibly that they were incredibly important from an engineering and scientific perspective.

For an engineer or artisan, to walk through the Temple of Luxor is an exercise in humility. Combining the logical, rational, and objective attributes of left-brain functions with the intuitive, subjective, and holistic qualities of the right brain, the experience of seeing these temples is suffused with profound sadness for a civilization that had risen to great heights and then suffered a cyclic decline.

In exploring what is left — the mere skeletons of the Egyptians' achievements — and then going beyond, a veil is lifted to reveal the incredible material loss of a people who created perfectly crafted buildings and statues from the hardest stones known to humankind. This ancient culture accepted the challenge to develop the tools to work glasslike stone — stone that was created by tremendous forces within the earth and spewed, or squeezed, from its fiery belly — to a high order of magnitude, proportion, and exactitude.

Basalt, diorite, and granite yielded to these ancient tools — the quartz crystals abundantly present in the granite and diorite gave way to the application of ancient technology now lost. Perfection was the goal, and the ancient Egyptians' stone-working craft, as we shall see, was perfected to the extent that exactness was achieved.

Even if our mind is not normally turned toward philosophy, a visit to Egypt soon finds our thoughts seeking refuge in ruminations of wonder at what once was and what could have (or must have) been had there not been an interruption. From the perspective of a philosopher, the mortality of physical existence is reinforced. We slowly realize that civilizations are like the human body — they have a life cycle. This is a discomforting thought for those who are faced with the implications of what Egypt's accomplishments mean. We become comfortable to the extent that we can master our environment, but eventually we all must yield to the ultimate master. The natural cycles of the universe and their concomitant forces of nature unleash death and destruction with as much indifference and impartiality as they provide what is necessary for life to exist.

The Temple of Luxor holds a message for our civilization — one that reaches across millennia through the ravages of time, and, though shaken, crippled, and on its knees, it implores us to pay attention.

I was with a delightful, eclectic group of people on a tour of Egypt in November of 2004. The tour was arranged by Andrea Mikana-Pinkham of Body Mind Spirit Journeys, and presenting on the journey were my good friends Stephen Mehler and David Hatcher Childress. A broad range of people from various backgrounds, including engineers, a pilot, salespeople, a doctor, a nurse, a minister, and, from Florida, a sassy barmaid with an infectious laugh, milled around the bus every morning in anticipation of another great day in the field. Everybody was having a wonderful time, and we all had one thing in common: a deep respect for the Egyptian culture and its monuments. Good humor and jokes flew around the bus like the swallows that swirl around the Great Pyramid at dawn.

Before 2004, I had not paid much attention to the temples in southern Egypt. Instead, I focused my attention on the pyramids and what I considered to be their more technical engineering attributes. As a part of this tour, I was fascinated by the story given by the Egyptologist tour guide, but I was not so fascinated that when an object caught my attention, I refused to wander off to do some exploring on my own.

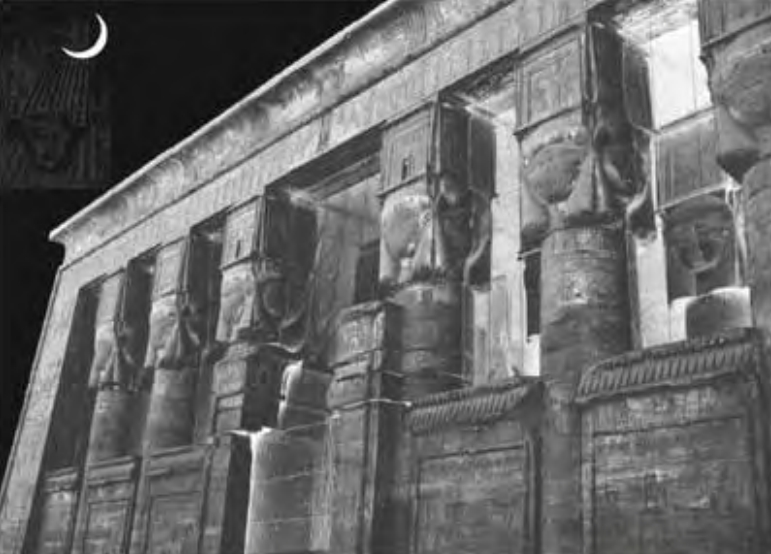

When you are part of a tour group, your visits to temples are strictly controlled. Generally, the tour operator takes you to Luxor at a time when it is the most visually stimulating: at night, when the temple is lit up with carefully designed and directed lighting. When you walk among the massive columns that reach to the sky like giant redwoods, the chattering of numerous tour guides fades as the power of the temple imposes its own majesty and voice onto your consciousness. This effect became more meaningful to me later, as my interest peaked and I began to learn more about the symbolic and philosophical interpretations that the temple has evoked from the hearts and minds of other researchers.

Figure 1.3. The Hedjet (front) with Pschent (back)

|

|

|

|

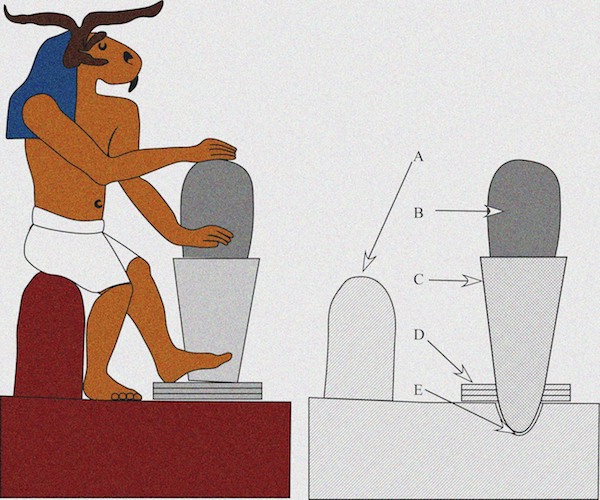

While our guide explained the meaning behind the intricately carved reliefs on the walls of the temples, several pieces of granite that were positioned in front of statues in the Ramses Hall — the first hall visitors enter after passing through the first pylon — managed to catch my attention. The explanations of the symbols on the walls suddenly lost their interest to me. Commanding my attention now were objects that appealed to a part of my nature that had been developed over many years of training and experience in manufacturing.

I recognized the granite pieces' faintly illuminated shapes as the cone-shaped crown of Upper Egypt: the Hedjet. Depicted as a white conical headdress in Egyptian art, images of the crown are found on the Narmer Palette and, famously, on the gold statue of the boy-king Tutankhamen. Another crown found in the Ramses Hall is the Pschent: a combination of the Red Crown of Lower Egypt and the White Crown that symbolizes the unification of the two Egypts. (See figure 1.3.)

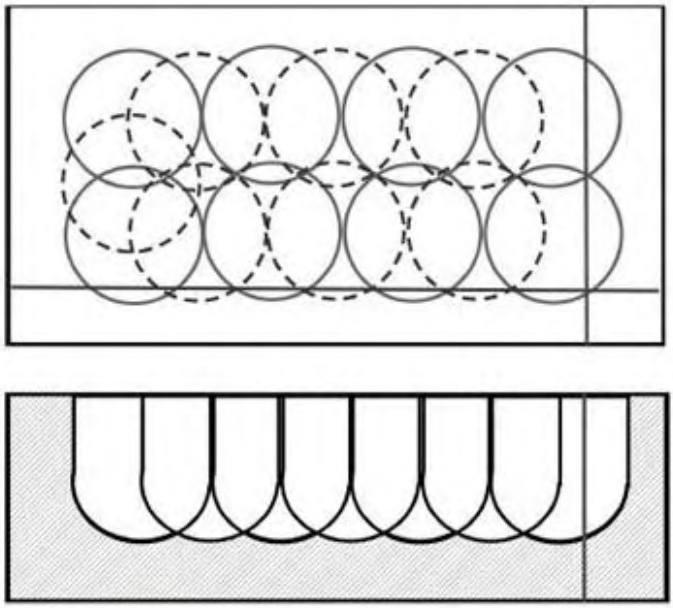

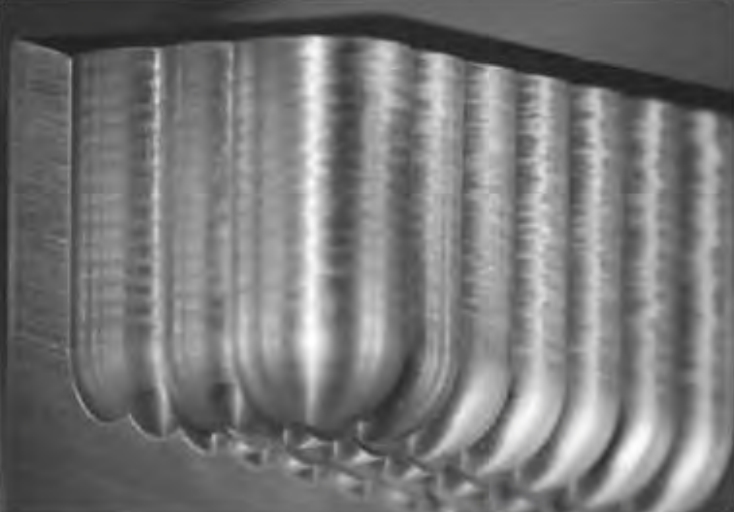

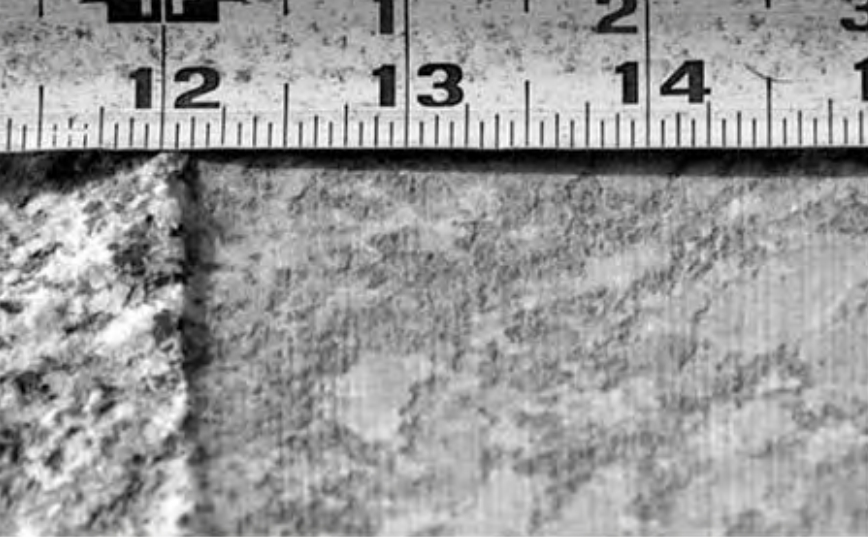

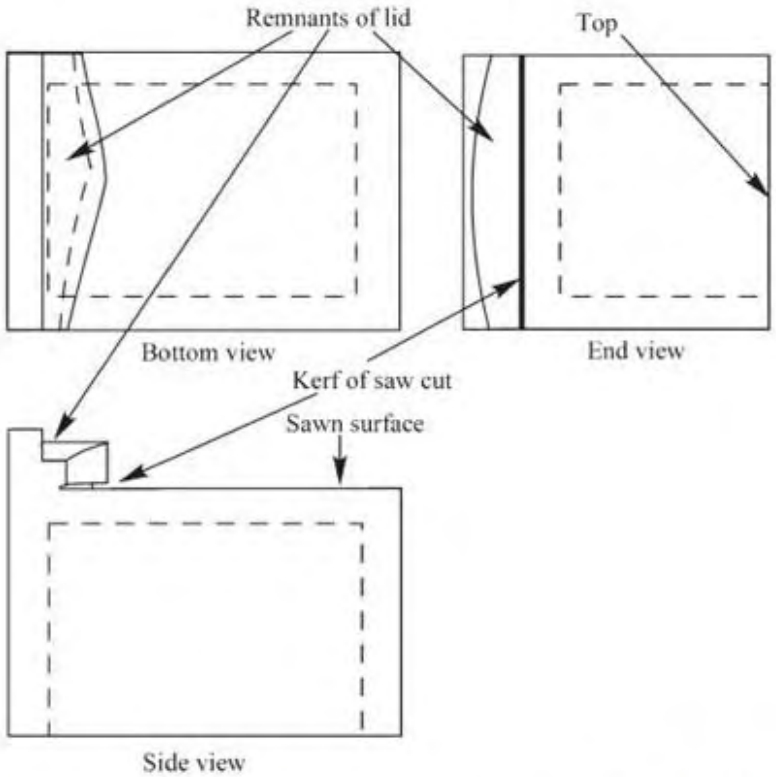

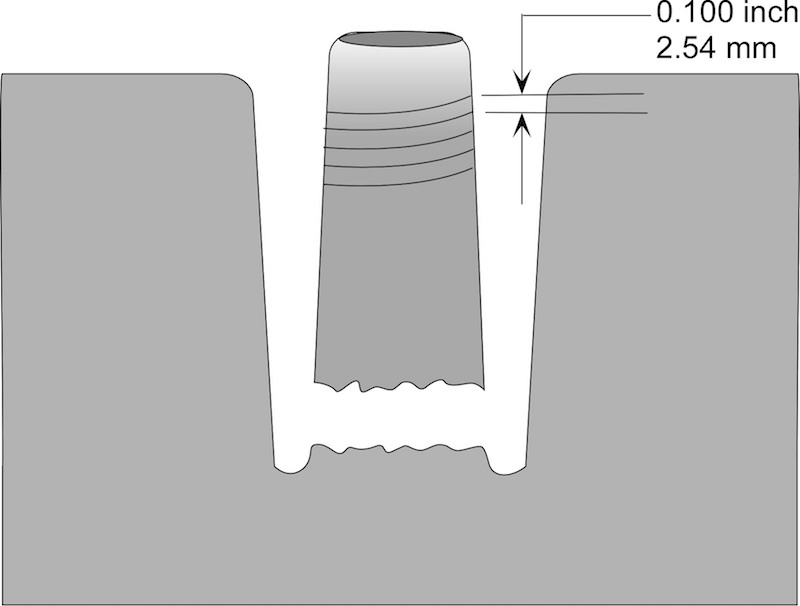

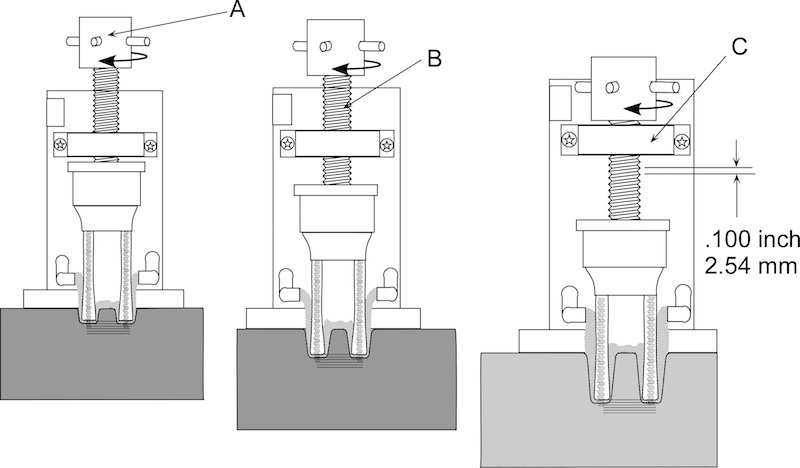

During this visit, I was able to examine them only visually and feel their smooth surfaces with my hand, but I was struck by their perfection of form, and I could not detect any deviation from a perfectly crafted contour. Throughout the course of my career, my hands have run across many different machined contours in order to find surface imperfections — and my contact with these Egyptian pieces seemed no different from my previous contact with objects that had been removed from a precision machining center. Except for some minor abrasions (presumably the result of the crowns falling to the ground) there were no pits or ripples or depressions in the compound curved surface. I felt only a flowing, exact surface that seemed as smooth as though it had been spun on a lathe. Because of its geometry, however, it would have been impossible to craft these crowns in such a manner. Along the length and width of each, the surface followed simple arcs that obviously were the result of careful deliberation in concept, design, and manufacture. From a cursory examination, it seemed clear to me that this result demanded adherence to geometry and precision in the manufacturing process.

This impression gnawed at me for a year, until I finally awoke to the realization that I had to go back and study them further. My opportunity to examine them again wouldn't come until February 2006, when I went to Egypt with John Anthony West on one of his Magical Egypt tours.

My main interest in going with West was to learn more about R. A. Schwaller de Lubicz, who had spent fifteen years at Luxor studying Amun-Mut-Khonsu and had concluded that it was built using a system incorporating precise measures that were a deliberate representation of the universe and man. Amun-Mut-Khonsu is, according to Schwaller de Lubicz, a material expression of cosmic correspondences. His magnum opus was translated into English in two volumes titled The Temple of Man1 It is considered a difficult work to understand, and West was one of the few people in the English-speaking world who knew Schwaller de Lubicz, supported his conclusions, and wrote about him in his own book Serpent in the Sky2 A more recent treatment of Schwaller de Lubicz’s work is The Spiritual Technology of Ancient Egypt, by Edward Malkowski.3

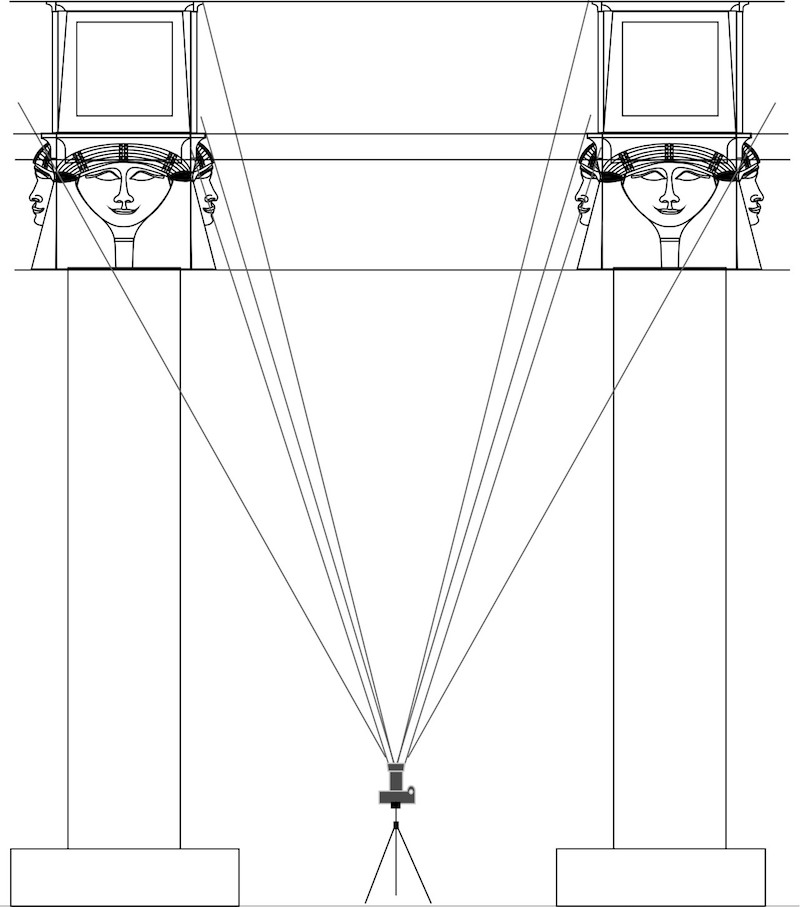

Before traveling with West, I bought a Canon digital Rebel XT 8-megapixel camera, and I took my laptop with me on the journey. Had I known at the time what my camera would reveal to me, I would have taken a good tripod too. Regardless, there is not much time for careful photography while on a tour because of time constraints, so it was more a matter of taking typical tourist photos — but doing so while striving, as best as circumstances allowed, to capture centered images of the crowns so that later I could evaluate their symmetry on the computer.

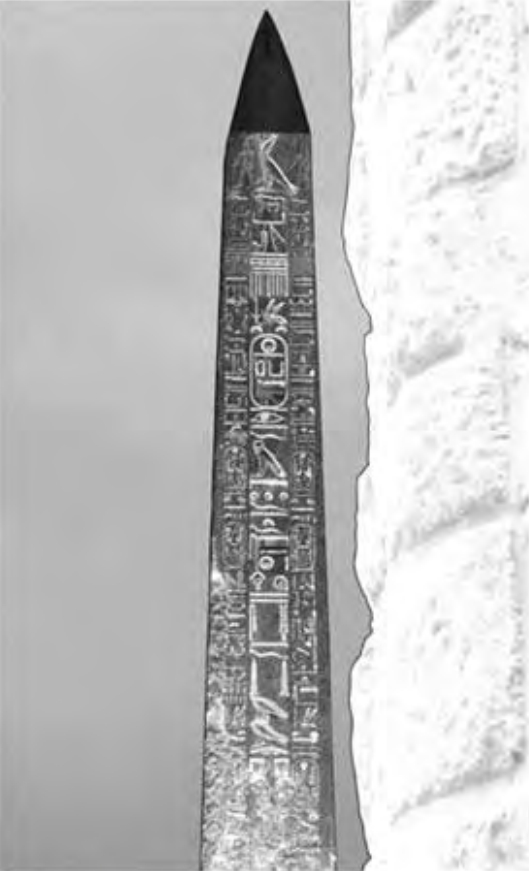

Because our visit to the Temple of Luxor was at night, I could not take the photographs I wanted of the crowns, so I photographed the Ramses statues and the bust near the obelisk outside as well as the obelisk itself, all the while attempting to keep the images square and the axis of the camera in line with the central axis of each object I was photographing.

The next day, after our excursion to Denderah and Abydos, I had the bus drop me off at the temple instead of the hotel in order to photograph the crowns in daylight. At this time, I was able to get better photographs just before dusk — the sun had barely disappeared behind the wall of the Temple, so it did not cast any sharp shadows. This allowed for a very evenly lighted shot that minimized distortions of the symmetries of the objects I wanted to measure.

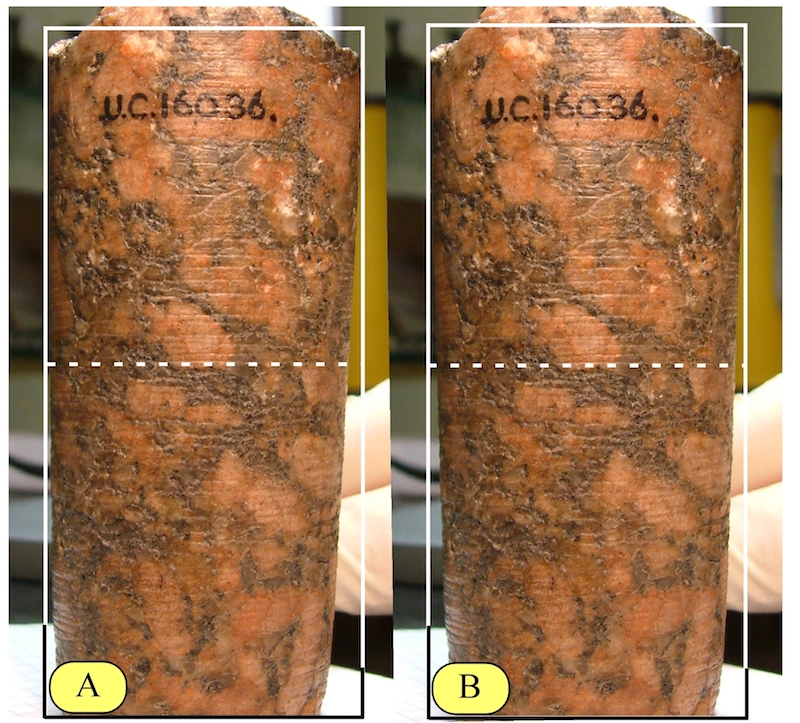

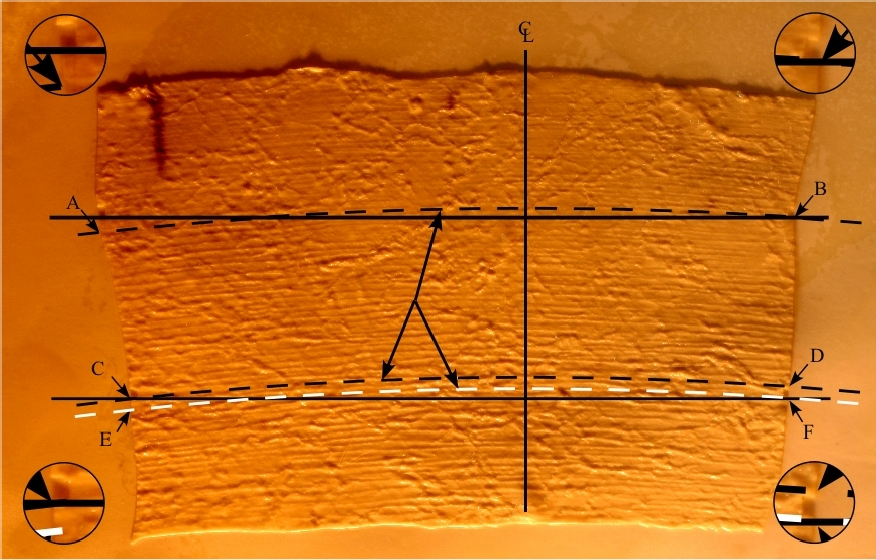

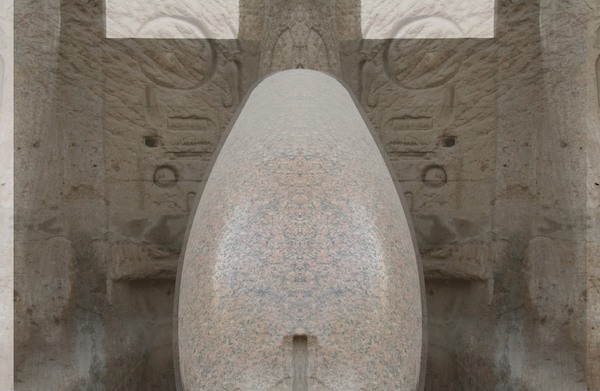

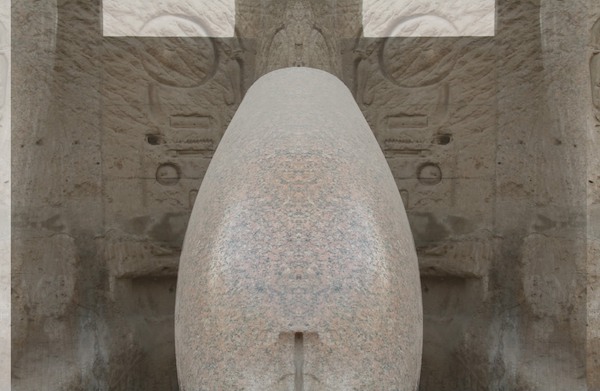

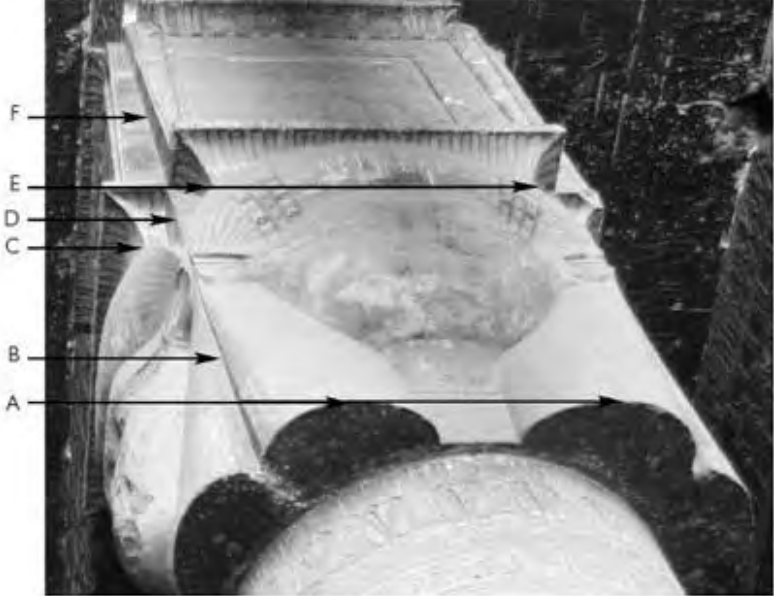

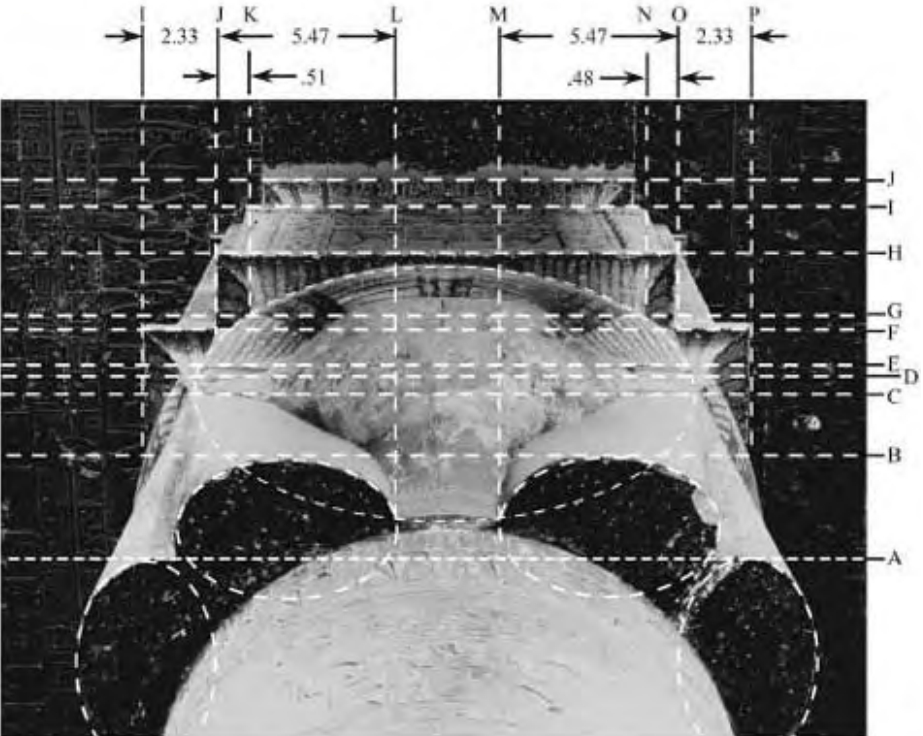

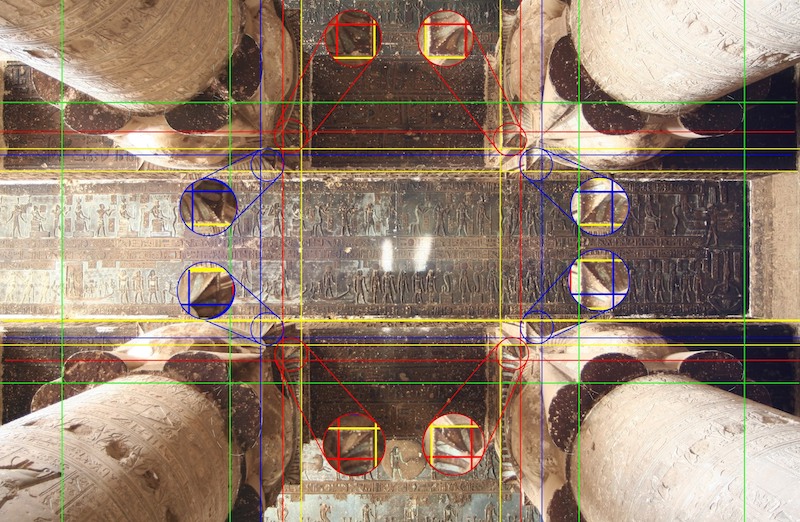

To a certain degree, my session was successful, and I was able to ascertain with some certainty that these crowns spoke an untold story. I took a digital image of one of the crowns and loaded it into my graphics program. I then duplicated the image and made a transparency of it so that I could compare opposite sides to determine if they were symmetrical. I discovered that they were — to a remarkable degree of accuracy. (See figures 1.4-1.6.)

1 R. A. Schwaller de Lubicz, The Temple of Man (Rochester, Vt.: Inner Traditions, 1998).

2 John Anthony West, Serpent in the Sky: The High Wisdom of Ancient Egypt (Wheaton, Ill.: Quest Books, 1993).

3 Edward Malkowski, The Spiritual Technology of Ancient Egypt (Rochester, Vt.: Inner Traditions, 2007).

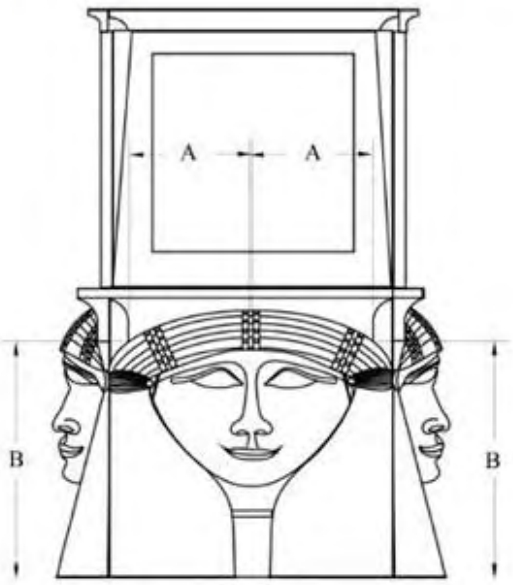

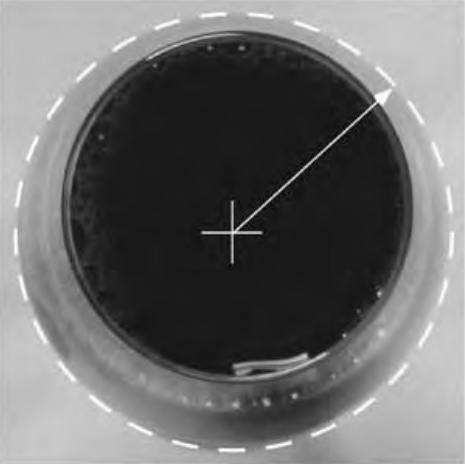

Figure 1.7. Hedjet symmetry with identical radii

|

|

|

|

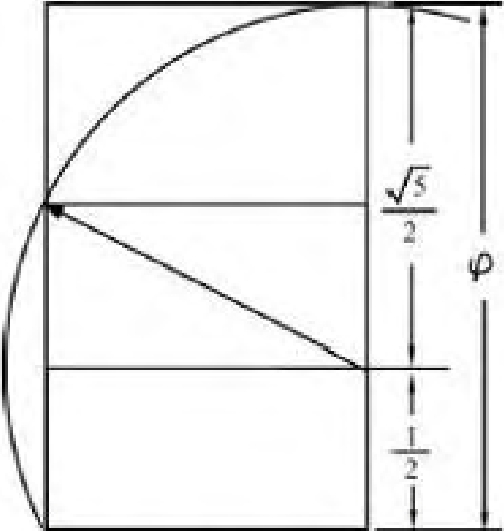

This symmetry, of course, compelled me to ponder how it was accomplished. In order to reverse engineer and duplicate an object, we must determine precisely the geometry encoded in its design. A few clicks of the mouse later, I had an answer to at least part of the geometry.

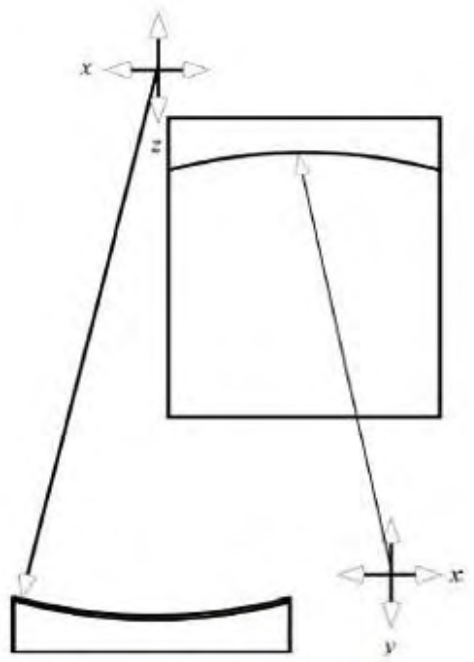

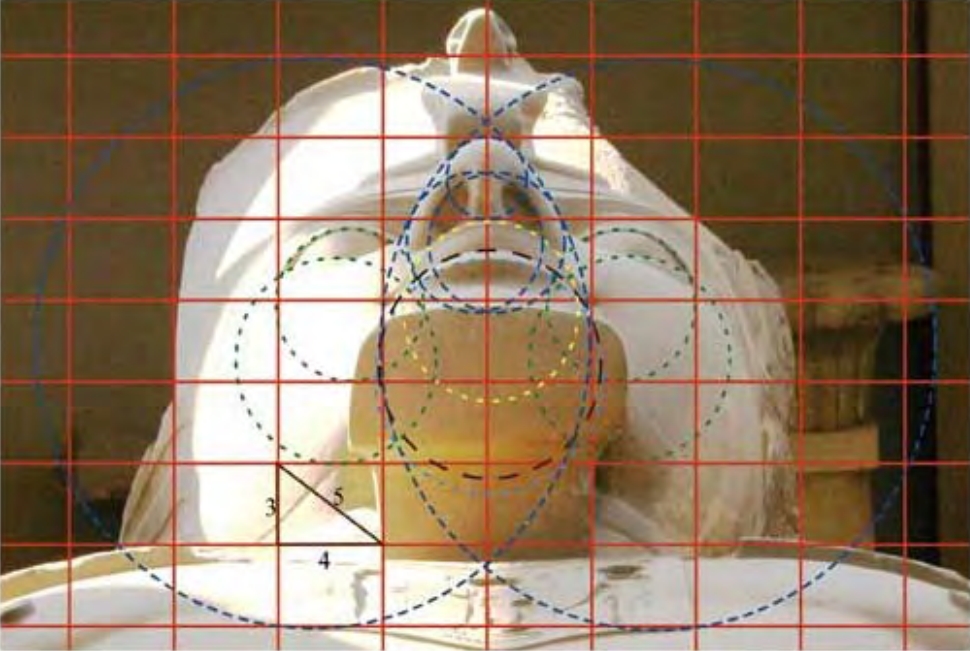

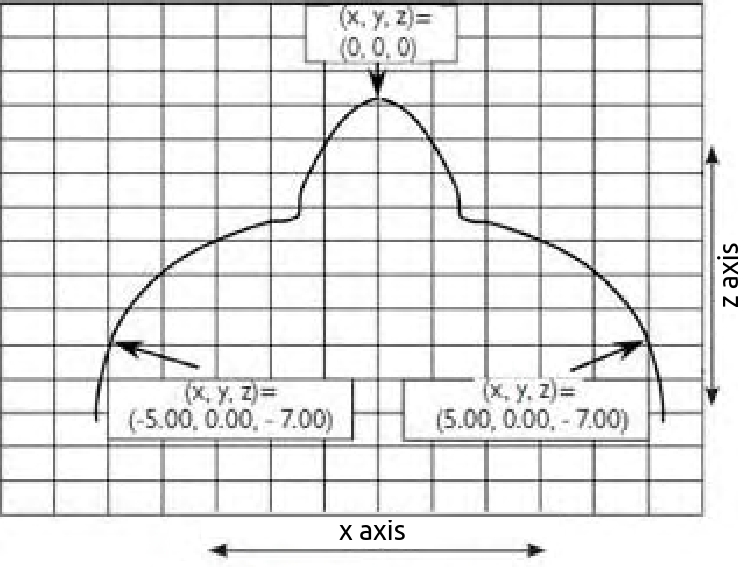

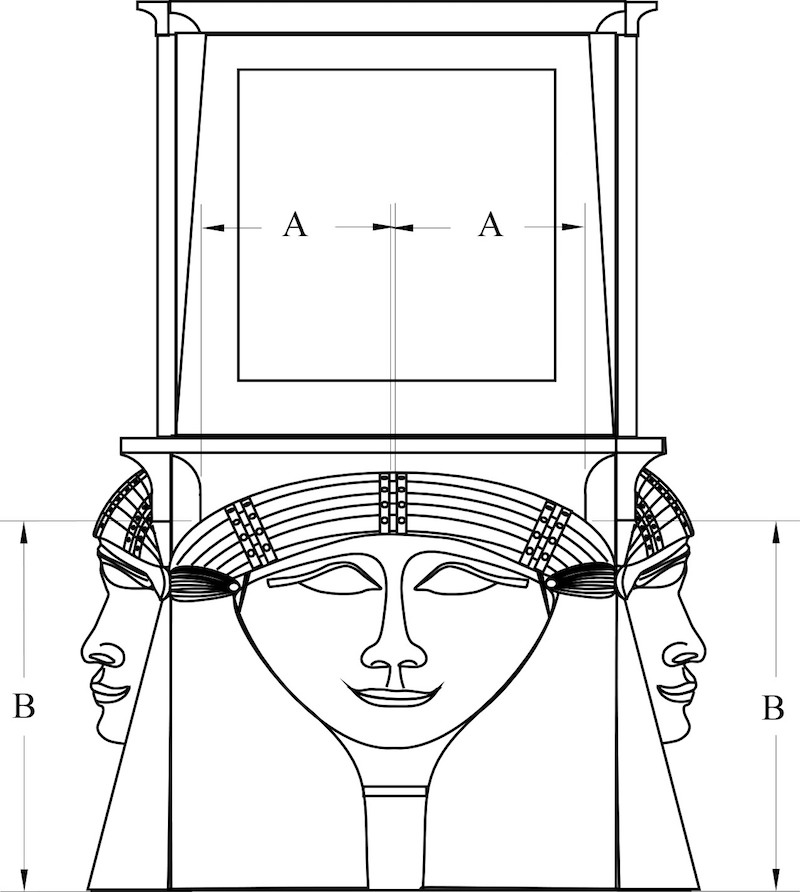

Figure 1.7 is a photograph of the front view of the Hedjet. It was taken as close to the center axis as possible so that the symmetry of the piece could be measured. As it turns out, we can determine fairly conclusively that the crown was designed and crafted to incorporate a true radius of the same dimension on both the left and right sides when the Hedjet is viewed from the front.

I analyzed another crown in the hall in the same way (see figures 1.8 through 1.10), and though it blends with the head of the pharaoh, it is crafted with a similar exact geometry.

On the first Hedjet, toward the top of the crown, the contour of the granite starts to move away from a true radius and follows another contour. We could determine exactly what that contour is if the crown was intact, but instead we must examine other crowns that do not have their tops broken off.

The next question that sprang to my mind was whether the radius was spun around a central axis — similar to the geometry on a bowling pin. Unfortunately, the answer to this question would take more time, because I had not taken any photographs of the Hedjet from the side — in fact, the question had not occurred to me until I was back at home, studying the photographs on my computer. When I was in the field, I was looking for symmetry and knew that the front and back were not symmetrical, so I didn't bother taking any photographs from that angle.

I was a bit chagrined that I didn't have the presence of mind to take those photographs, but I continued working with the ones I did have and determined that I absolutely had to return to Egypt and finish what I had started — or at least I had to take this mode of inquiry to the next level within my reach. I believed that at Luxor I had discovered a quality and precision of manufacturing granite that rivaled or surpassed what I had studied near the pyramids in Lower Egypt.

Because I had already taken two weeks of vacation, Judd Peck, the CEO of Danville Metal Stamping, my employer, was a bit perplexed when I asked for more time and told him that I needed to go back to Egypt when I had returned only a couple of weeks earlier. To convince him that the trip was legitimate, I shared with him what I had discovered in my many photographs.

Judd Peck is the president and CEO of a gas turbine engine manufacturing company with 410 employees. He is also a member of the Illinois Bar and a well-respected attorney in the community with impeccable judgment and common sense. After viewing the photographs for thirty minutes, he nodded and said, "I see what you mean."

The next day, I received a surprise: Judd came to my office and asked me if I was traveling alone to Egypt. What he had seen must have inspired him — he asked if he could tag along and carry my tripod. Of course, I was delighted to have him as a traveling companion, and in the last part of April through the first part of May, we went to Luxor to continue taking more tourist photographs.

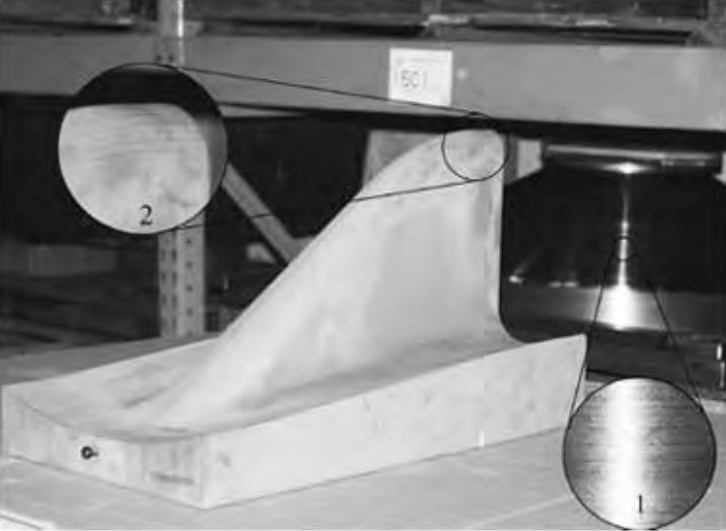

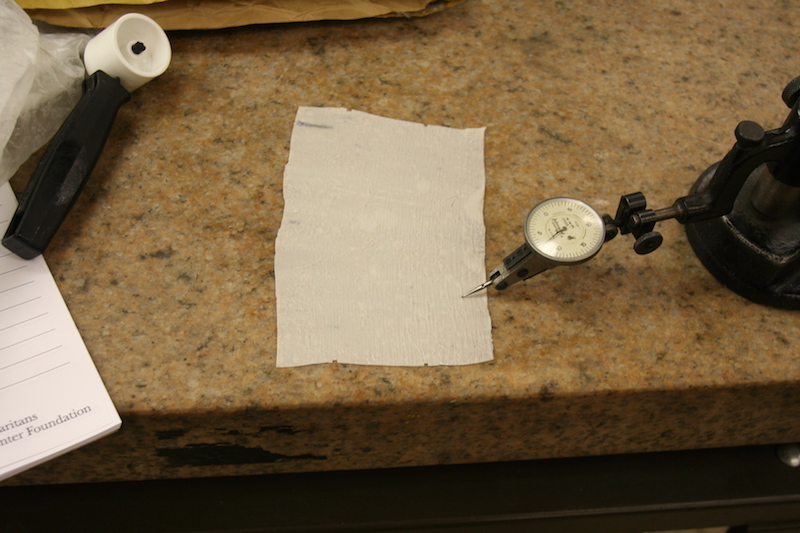

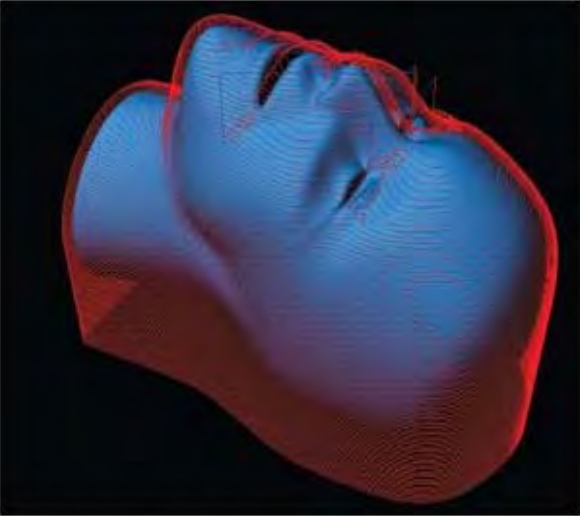

As it happens, the quality department at Danville Metal Stamping had recently reviewed some new technology called Capture 3D. This uses digital photography to take a stereo image of a contoured surface and then imports the images into proprietary software. The accuracy of the surface is compared to a computer model design and the imperfections are highlighted. In the world of metrology — the science of measurement — it is a relatively new technology, but one that yields reliable results. Judd and I were part of a panel that reviewed the technology and, in doing so, learned about some of the other work that had been performed by the company, such as digitizing and creating computer replicas of the statues on the Charles Bridge in Prague, in the Czech Republic.

With that resource in mind, I gathered some more equipment to assist me in my task: a sturdy Manfrotto tripod, a right-angle viewer, a telephoto zoom lens with macro focusing, and a wide-angle lens. Along with my digital camera, I brought to Egypt a film camera that accepted the same lenses.

The first day in Luxor we visited the Temple of Amun-Mut-Khonsu and spent about six hours there with very few tourists present. On this trip I discovered that it is best to experience the temples of Egypt in silence. I'm not sure how the ancients experienced these structures, but emanating from them — seemingly inversely proportional to the level of ambient noise — is a profound majesty. The hum of the city was an omnipresent background during my viewing, but within the colonnades and sanctuary of the temple itself, city sounds faded to insignificance and all was stillness and quiet. Similarly, on another trip that Judd and I took to Denderah, we were lucky enough to be there when all the tour buses had left. We spent several hours enjoying that temple in silence.

I found myself absorbed in thought as I went to work taking a set of photographs of artifacts that for months had consumed my mind with their overwhelming uniqueness. My thoughts turned to the recent Internet competition for the new list of Wonders of the World. I thought it was ironic that the Wonders of the World that I framed in my camera viewfinder on this visit were not even mentioned. In terms of beauty and the knowledge and skill they illustrated, the statues of Ramses II at Luxor and other locations in Egypt surpassed all other competition candidates in terms of advanced geometry and complex manufacturing precision in one of the hardest-to-work materials known to mankind. As I hope to demonstrate here, the statues of Ramses challenge the Giza pyramids themselves as the most perfectly engineered artifacts of ancient Egypt — and perhaps of human history.

The polished glint of granite again compelled me to run my hand over its smooth, but now familiar contour. Again, I marveled at the feat of engineering and the fact that the granite crowns were originally placed on top of the heads of the Ramses statues that populate the precincts of the temple. Some of these statues are 40 feet tall, beyond the scrutiny of earthbound observers, yet the creators of these wonders had seen fit to place upon them crowns that were carved with, what I suspected from my examination so far, extraordinary exactitude.

Figure 1.11. The Hedjet, side and front

Figure 1.12. Front, side, and angled view of a crown

|

Setting to work with my camera, I began to take more photographs, and I captured the images I failed to get the last time I was in Egypt. This time, my camera was firmly mounted on a tripod stand with a remote shutter-release button.

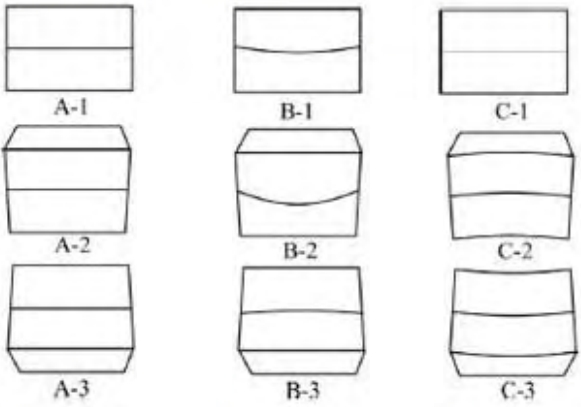

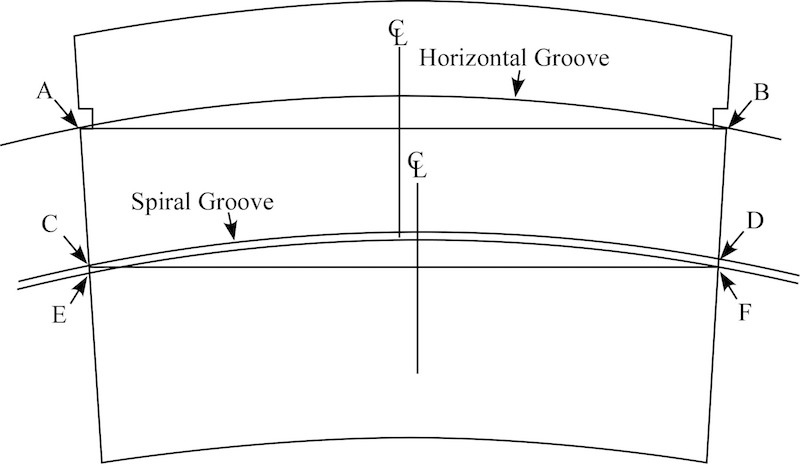

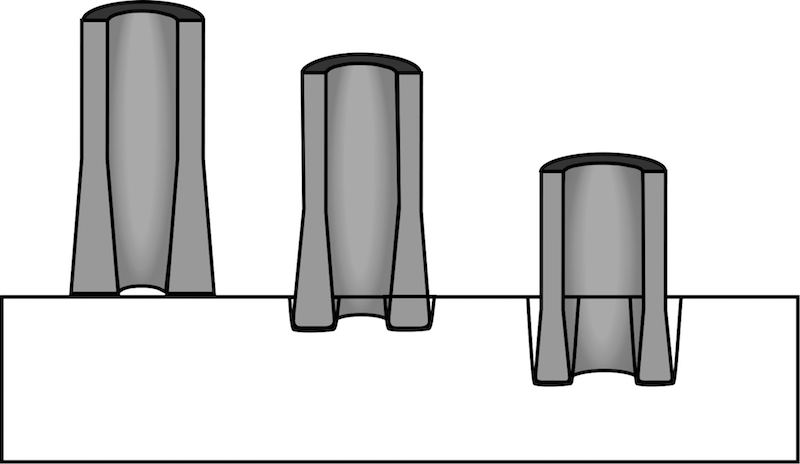

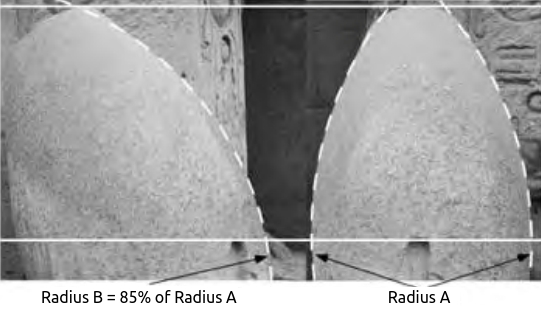

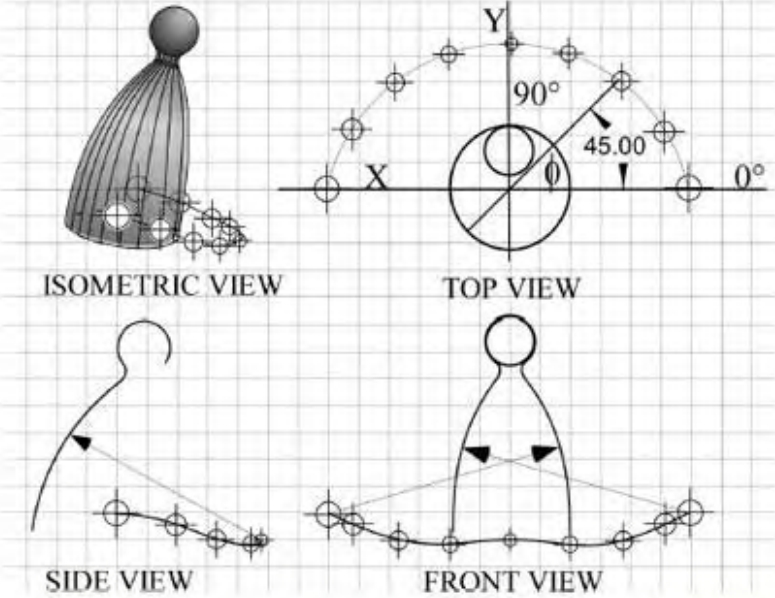

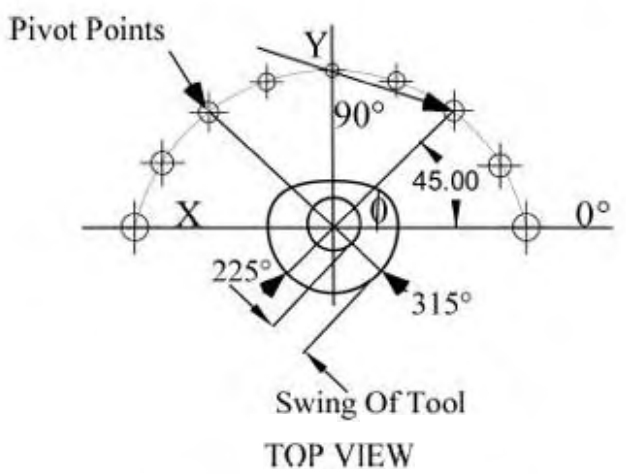

When I took the side-view photo of the Hedjet depicted in figure 1.7, I was unable to get a perfect right-angle view of the front because of barriers in the vicinity: A pillar was close to one side, and another crown was close to the other, but I was able to set the tripod to the side and obtain a shot at about 75 degrees. Upon review of the image, the answer to my previous question was answered: the side view of the Hedjet revealed that the contour on the front was also a true radius. Interestingly, though, at this angle, the radius had reduced in size by about 15 percent. (See figure 1.11; Radius B is 85 percent of Radius A.) Moreover, as the radius transitioned from the side to the front, the center point of the radius moved down slightly.

Fortunately, there were other crowns to study, and I set up my camera to focus on another on the west side of the hall — one of three crowns that had been placed in front of three statues positioned between the columns. In taking the series of photographs shown in figure 1.12, I attached a compass to the tripod and moved the camera around the crown in 45 degree increments. When I analyzed the results in the computer, I was astounded at the amazing accomplishment of these ancient craftsmen and, more important, of the fact that they saw fit to design these crowns to incorporate such a difficult and complicated work of art and engineering. From a conceptual and design standpoint, designing the crowns in this way would be a fairly straightforward task, but did the designer have any idea what he was asking of the craftsperson who would cut his design into stone? He might have said to his friends, "Hey, want to see what I did to drive the guys in the shop crazy? I just made the design of the crown exponentially more difficult to manufacture."